Steel wire mesh frame hollow wall board and preparation method thereof

A technology of wire mesh frame and hollow body is applied in building materials, building components, buildings, etc., to achieve the effect of reducing cost, clear process steps and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

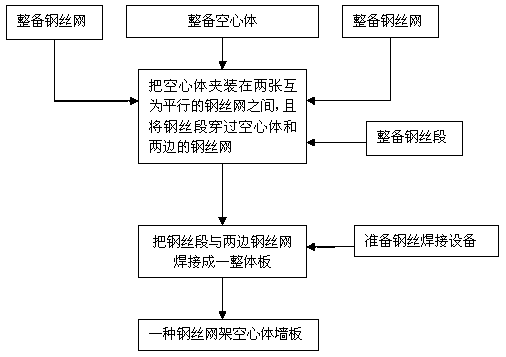

[0010] The following examples further illustrate the process of the preparation method of the present invention: see appendix figure 1 , the present invention can implement the manufacture of the steel mesh frame hollow body wallboard according to the required size and thickness. The specific steps are: first prepare the hollow body; prepare two steel wire meshes; prepare the steel wire section; prepare the steel wire welding equipment, clamp the hollow body between two steel wire meshes that are parallel to each other, and pass the steel wire section through the hollow body and The steel wire mesh on both sides is welded by welding equipment to the steel wire section and the steel wire mesh on both sides to form an integral plate, which constitutes the steel wire mesh frame hollow body wallboard.

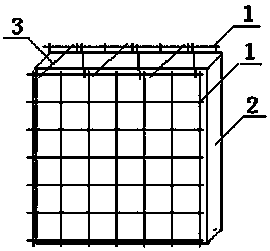

[0011] combine figure 1 and see figure 2 According to the embodiment, the steel wire grid hollow body wallboard and its preparation method can be further elaborated: the hollow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com