Cmp pad conditioners and associated methods

a conditioner and pad technology, applied in the field of cmp pad conditioners, can solve the problems of forming asperities in the cmp pad, reducing the degree of so as to reduce minimize the compression of the cmp pad. , the effect of reducing the compression of the cmp pad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0073]A PCD compact with sintered polycrystalline diamond coupled with cemented tungsten carbide substrate is used as a blank for EDM machining. The compact disk has a diameter of 34 mm (e.g. Adico), 52 mm (e.g. Adico), 60 mm (e.g. Diamond Innovations), 74 mm (e.g. Element Six), or 100 mm (e.g. Tomei Dia). The typical PCD layer is 400-600 microns thick. The total thickness (including the WC substrate) can be 1.6 mm or 3.2 mm as standard materials.

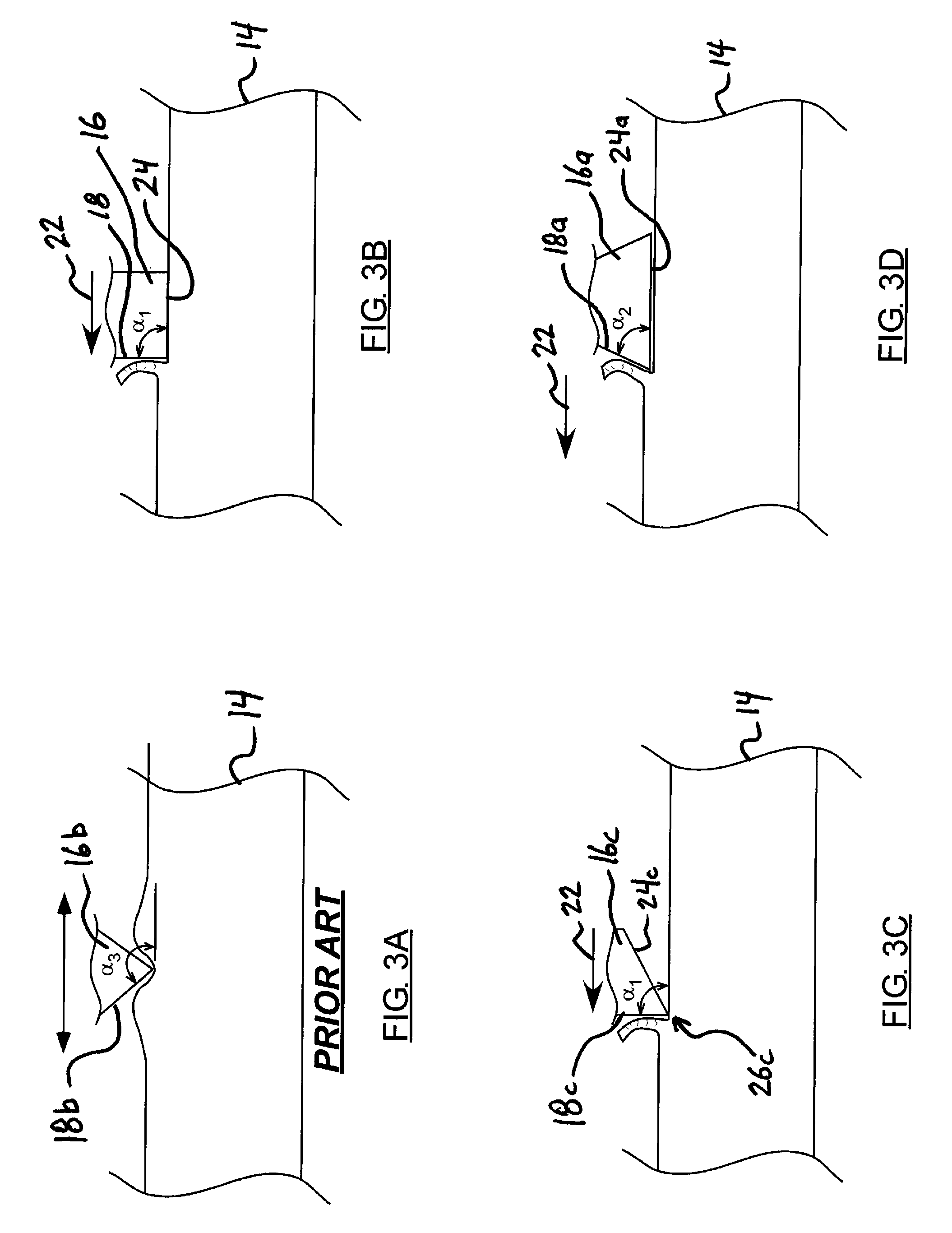

[0074]The PCD surface is fine polished to have an Ra less than about 1 micron. The blank is wire-EDM cut to form zigzag pattern with tip-to-tip distance of about 400 microns and tip-to-valley depth of about 100 microns. The tip angle can be 60, 70, 60, 90 or 100 degrees (relative to a finished surface applied to a pad), which can be varied by the computer setting for traversing the PCD blank. The zigzag pattern produces symmetrical profiles on the vertically sliced blades. The blade (e.g., cutting element) thickness can be less than about 1...

example 2

[0080]A process similar to that described in Example 1 is used, except that a WC blank is used instead of PCD. The WC blank contains a low amount of cobalt (e.g. 6 wt %). The straight blades are set in a fixture and placed in a CVD reactor with methane (1%) hydrogen mixture that is thermally decomposed and dissociated to form carbon and atomic hydrogen. The CVDD coated WC will deposit diamond grains with sharp cutting tips that can be spaced by controlling the nucleation density, sparse nuclei distribution, larger grains, and higher protrusion and further separation. The diamond grains can range from nano crystalline (i.e. the edge is straight) to grains with larger than 10 microns. The low cobalt amount in WC can help diamond retaining by avoiding the back conversion due to its catalystic ability.

example 3

[0081]A process similar to that described in Example 2 is used, except that the blade is sliced from a silicon infiltrated SiC blank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com