Thread hooking apparatus of button-sewing machine

A button sewing machine and thread hooking technology, which is applied to the thread cutting mechanism, thread breakage detector, sewing machine components, etc. in the sewing machine, which can solve the problems of stitch deviation, poor finishing quality, lack of stability, etc., and achieve the elimination of stitches The effect of the deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below with reference to the drawings.

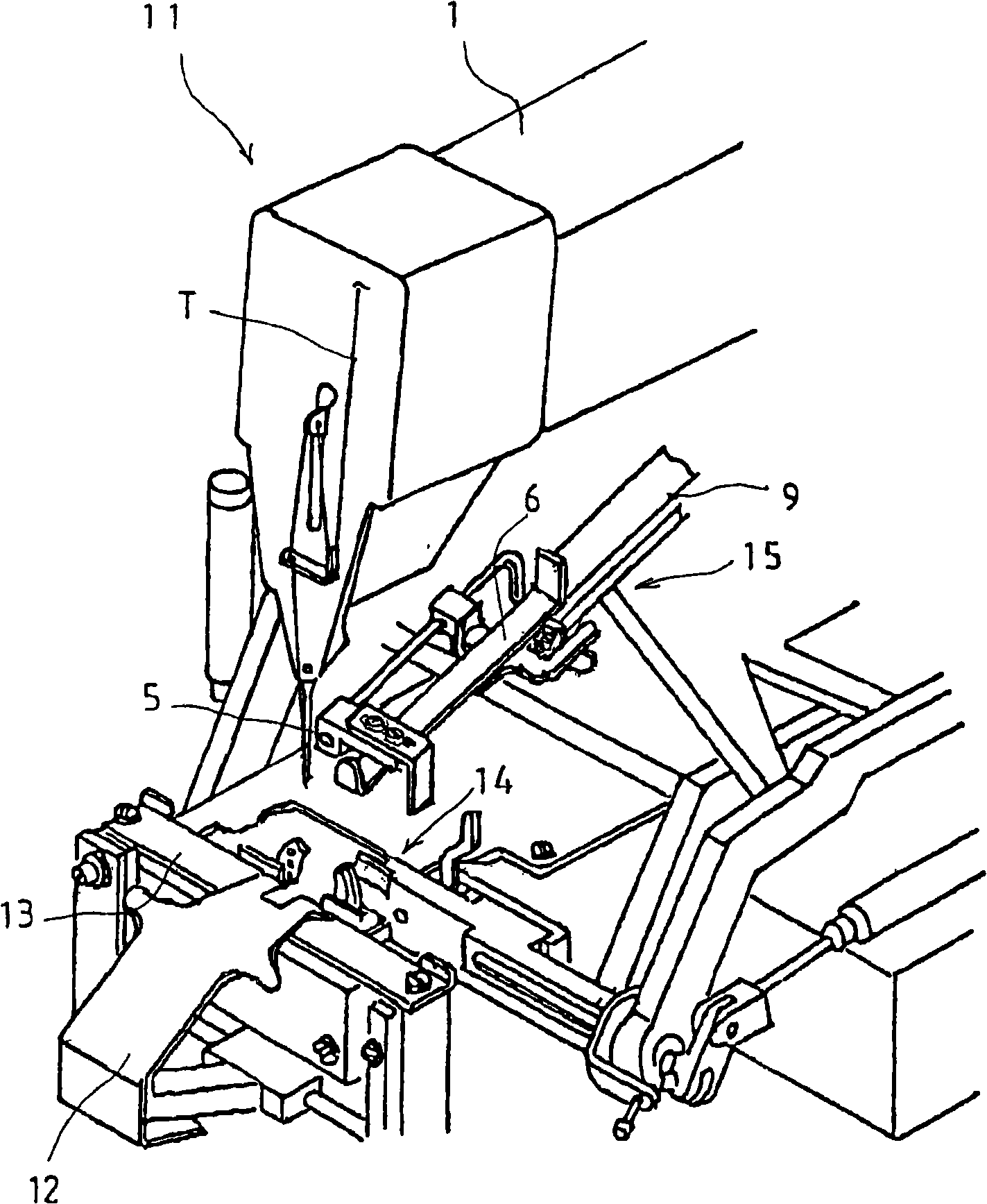

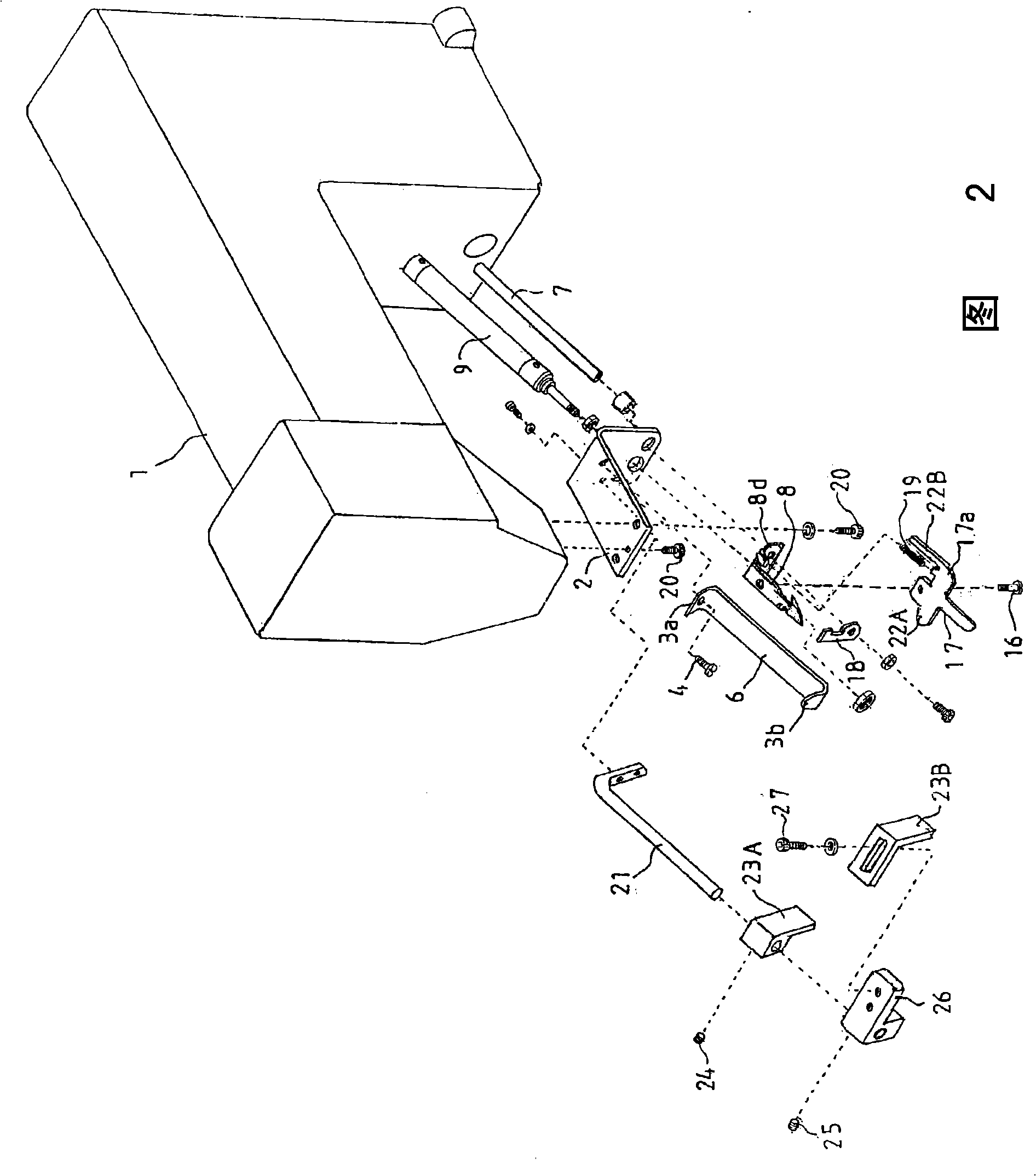

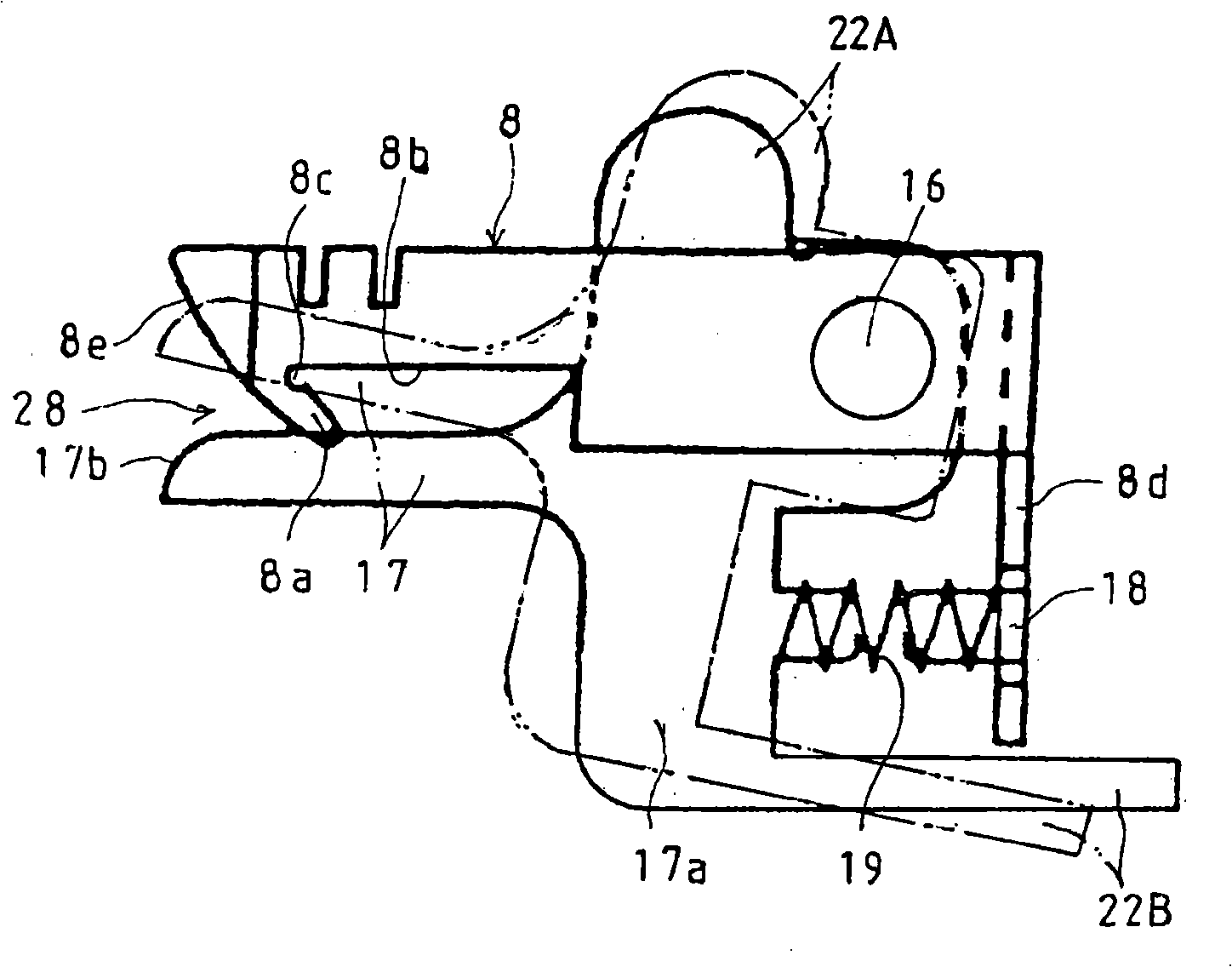

[0025] figure 1 It is a schematic overall perspective view of the button sewing machine of the present invention. Fig. 2 is an exploded perspective view of a thread hooking device as a main part of the present invention. In the following description, the same components and the same parts as those of the conventional structure shown in FIGS. 7 and 8 will be described using the same reference numerals.

[0026] First of all, the button sewing machine 11 is provided with a needle 5 that reciprocates up and down at a certain position through the lifting drive mechanism provided in the sewing machine casing 1, and is equipped with a needle 5 to be sewn in the front part of the up and down movement path of the needle 5. The cloth (not shown) of the button (not shown) is adjusted to the cloth holder 12 on the up and down movement path of the needle 5 in the state of being folded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com