Deburring die for numerical control turret punch press

A CNC turret punching machine and mold technology, which is applied in the field of CNC machine tools, can solve the problems of large polishing marks, unfavorable health of operators, and difficulty in unifying manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

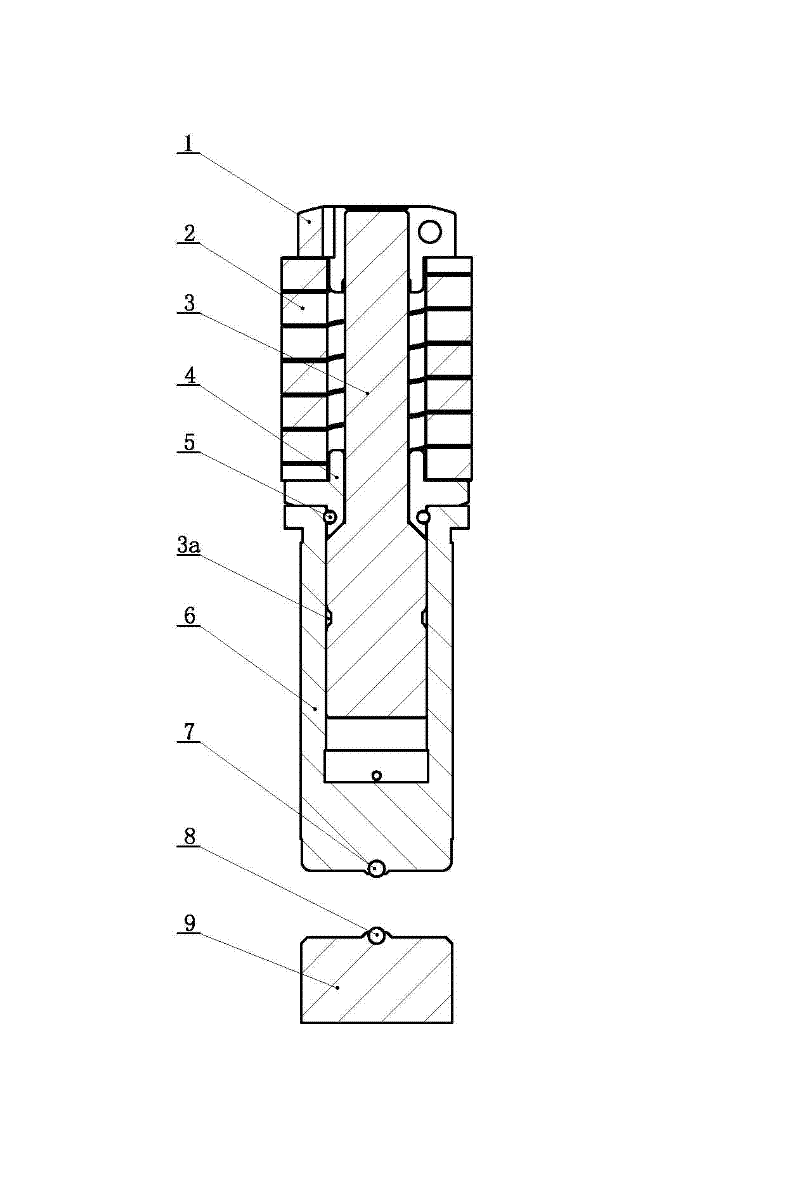

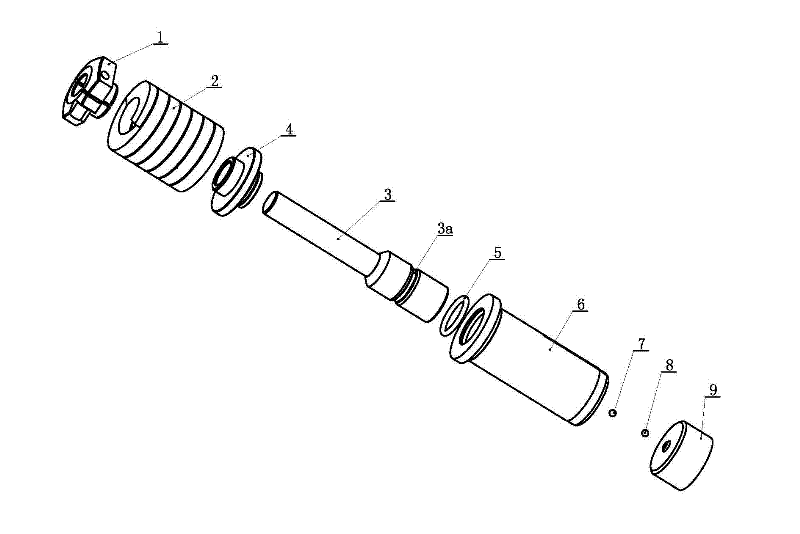

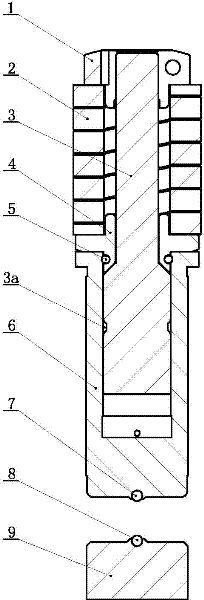

[0013] like figure 1 and figure 2 As shown, the deburring die for the numerical control turret punch of the present invention includes an upper die and a lower die having a common axis; the upper die includes an upper die rod 3, an upper die spring 2, a die nut 1, a spring seat 4 and a guide sleeve 6 , the upper die rod 3 is in the shape of a stepped cylinder with a small upper part and a large lower part, and the middle part of the upper die rod 3 is provided with a conical surface that connects the upper part and the lower part; the die nut 1, the upper die spring 2 and the spring seat 4 are in order from top to bottom. Set on the upper part of the upper die rod 3, the die nut 1 is screwed on the upper end of the upper die rod 3 to compress the upper die spring 2, the lower end of the upper die spring 2 is supported on the convex ring of the spring seat 4, and the lower end of the spring seat 4 The end face is supported on the conical surface in the middle of the upper die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com