Polishing film

a technology of polishing film and film layer, which is applied in the direction of manufacturing tools, other chemical processes, chemistry apparatus and processes, etc., can solve the problems of difficult removal of adhered abrasive particles, scratching and chipping, and light loss on the connecting end surface, so as to achieve excellent polishing finished quality, inhibit effect, and present invention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0071]An application liquid was prepared by mixing 66 parts by weight of organo silica sol (MEK-ST manufactured by Nissan Chemical Industries, Ltd., solid content: 30% by mass) as abrasive particles containing SiO2; 3.9 parts by weight of acrylic resin (Acrynal #22-36 manufactured by Toei Kasei Co., Ltd., solid content: 29.6% by mass) as a binder resin; 0.5 parts by weight of isocyanate (Sumidule L75 manufactured by Sumika Bayer Urethane Co., Ltd., solid content: 75% by mass) as a cross-linking agent; and 0.3 parts by weight of phosphoric acid (solid content: 85% by mass) as an anti-adhesive agent into a mixed solvent of 25.3 parts by weight of methyl ethyl ketone, 3.8 parts by weight of 2-propanol and 0.2 parts by weight of purified water (manufactured by TRUSCO Nakayama Corporation).

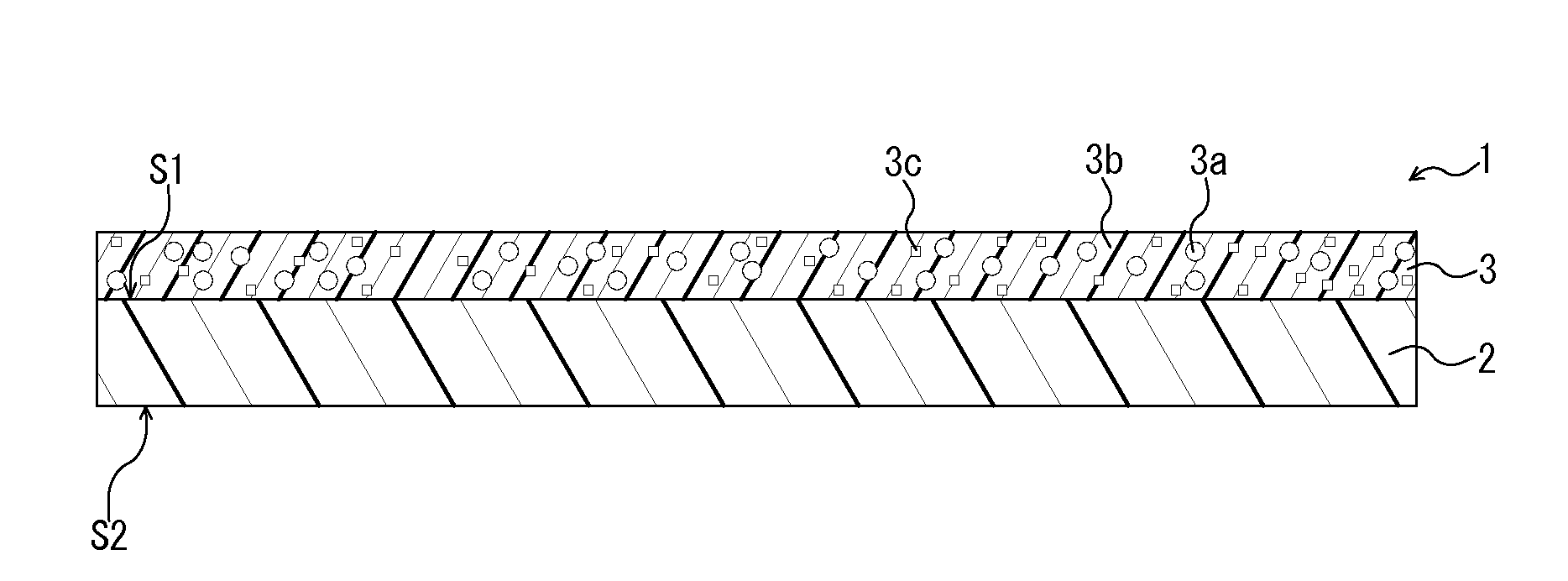

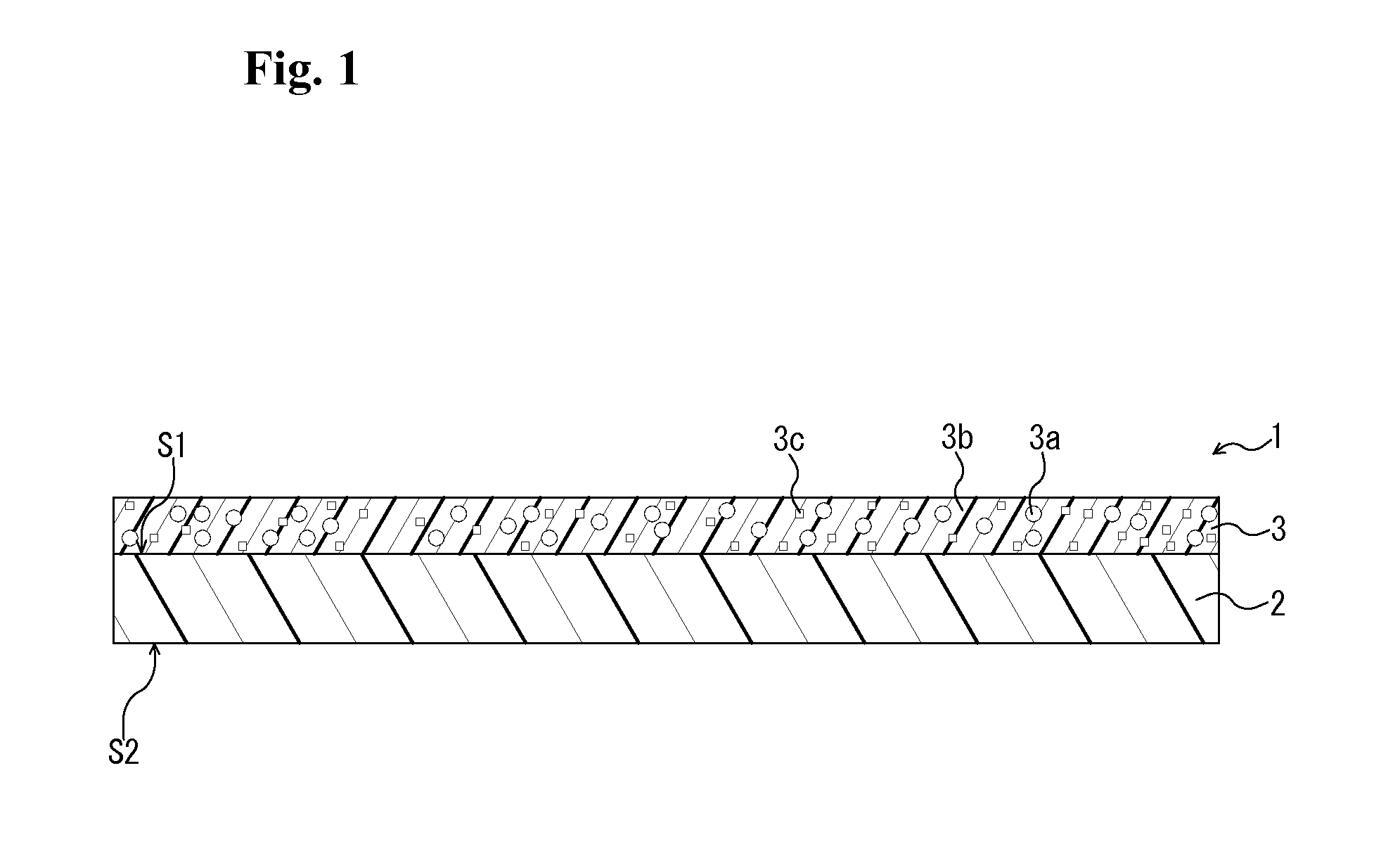

[0072]The application liquid was applied onto one surface of a polyester film (Lumirror T91N manufactured by Toray Industries, Inc., thickness: 75 μm) as a substrate, using a bar coating method, and th...

example 5

[0078]A polishing film 5 was produced as similar to Example 1 except for using phosphonoacetic acid (manufactured by Wako Pure Chemical Industries, Ltd.) instead of phosphoric acid as an anti-adhesive agent, and the evaluation test was conducted. Results were shown in Table 3.

TABLE 3Example 5Proportion inCompound nameapplicationProportion in(solid content proportionliquid (parts bypolishing liquid(% by mass))mass)(% by mass)1Organo silica sol (30)66.091.52Acrylic resin (29.6)3.95.33Methyl ethyl ketone (0)25.304Isocyanate (75)0.51.75phosphonoacetic acid (100)0.31.462-propanol (0)3.807Purified water (0)0.20Evaluation results:94efficiency percentage (%)

example 6

[0079]A polishing film 6 was produced as similar to Example 1 except for using cellulose resin (Ethocel 100 manufactured by Nisshin & Co., Ltd.) instead of acrylic resin, and the evaluation test was conducted. Results were shown in Table 4.

TABLE 4Example 5Proportion inCompound nameapplicationProportion in(solid content proportionliquid (parts bypolishing liquid(% by mass))mass)(% by mass)1Organo silica sol (30)66.092.02Cellulose resin (100)1.15.13Methyl ethyl ketone (0)28.104Isocyanate (75)0.51.75Phosphoric acid (85)0.31.262-propanol (0)3.807Purified water (0)0.20Evaluation results:90efficiency percentage (%)

[0080]As it is clear from the results shown in Tables 2 to 4, if the polishing film of the present invention is used, it is difficult for abrasive particles containing SiO2 to be adhered onto a polishing surface, such as an end surface of the optical fiber body after polishing, even when water containing impurity ions is used as a polishing liquid, and excellent polishing finish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com