Method and device for applying additive packaging material

a packaging material and additive technology, applied in the field of methods and devices for applying additive packaging materials, can solve the problems of limiting processing speeds, unsatisfactory cutting, and relatively easy failure of separating means running partially around the periphery of supply means, and achieve the effect of constant speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

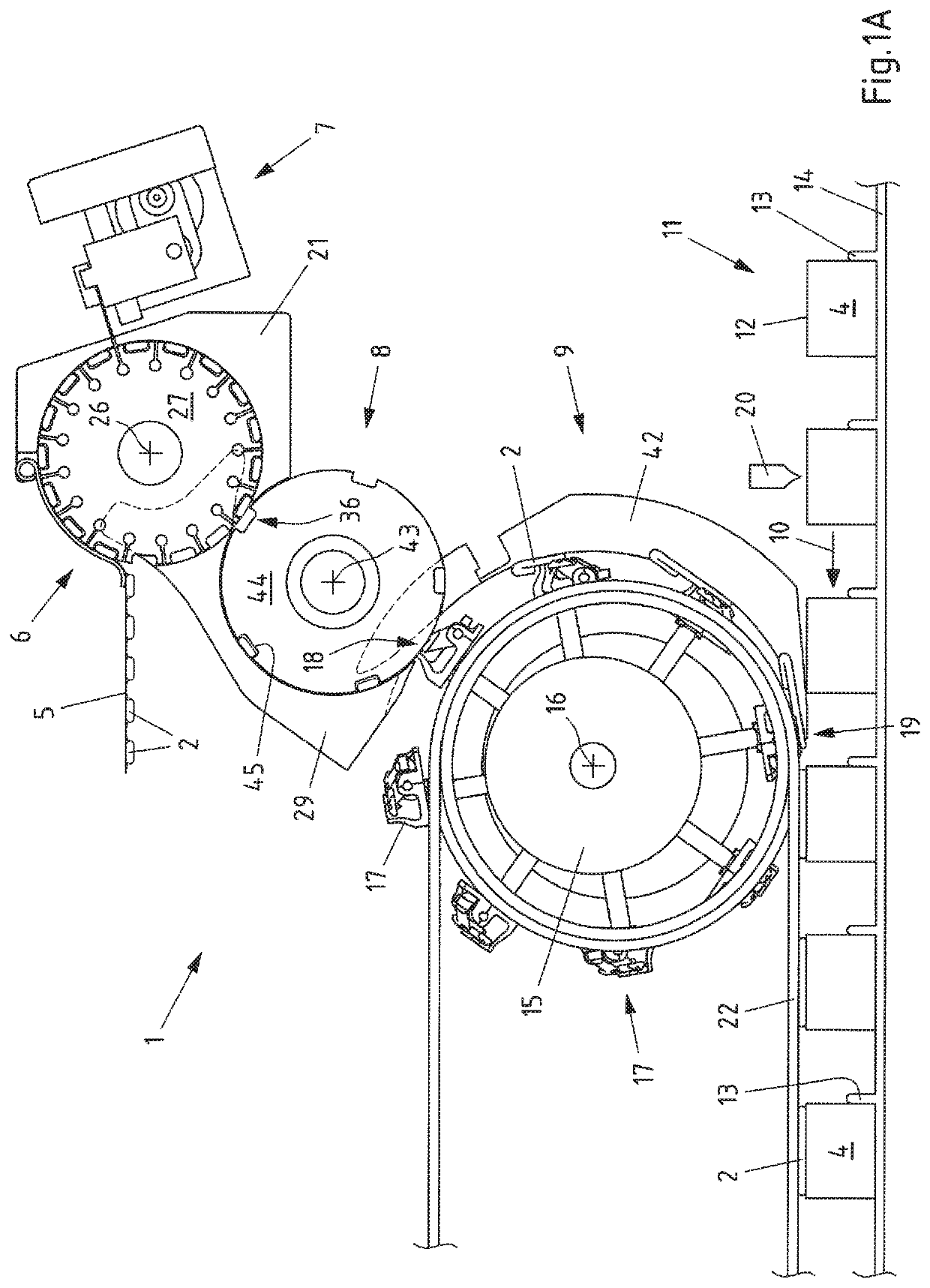

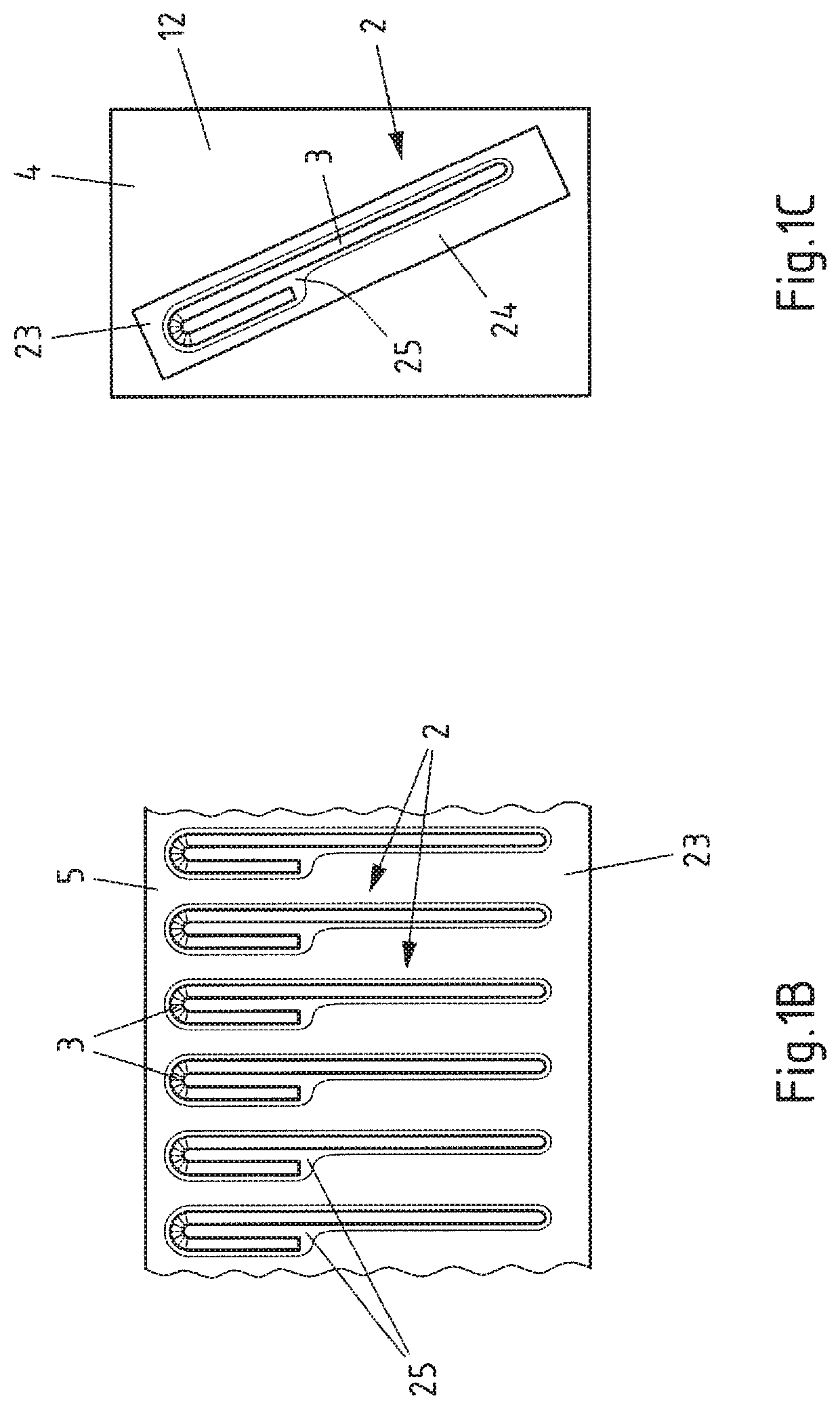

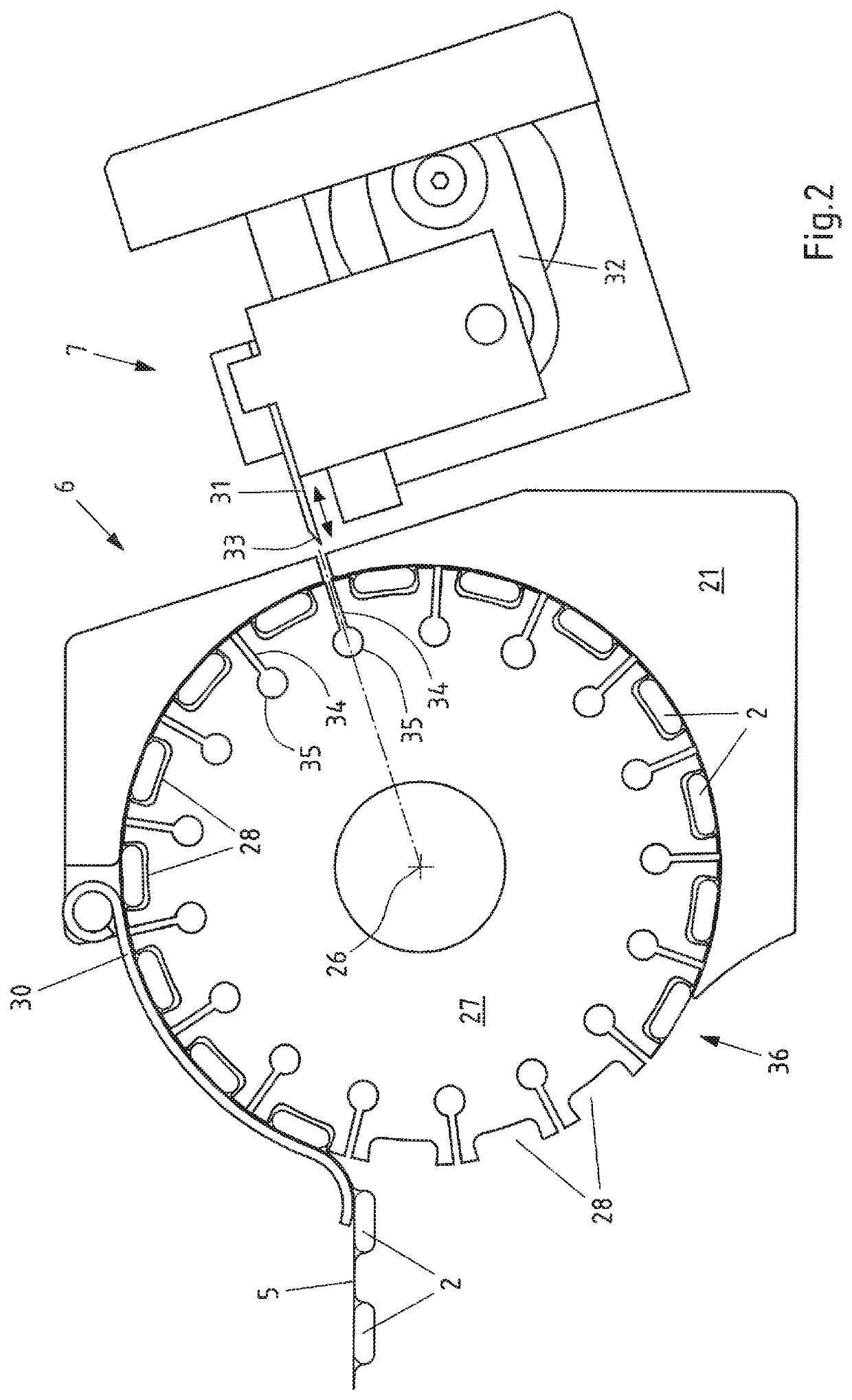

[0043]FIG. 1A shows a device 1 for applying additive packaging material 2 in the form of wrapped straws 3 to previously filled and sealed packages 4 in the form of cardboard composite packages, which here are designed as drinks carton composite packages. The additive packaging materials 2 are pulled into the device 1 from a supply means 6 in the form of an additive packaging material continuous belt 5, which device supplies the additive packaging material continuous belt 5 to a separating device 7. The separating device 7 separates the additive packaging material continuous belt 5 into individual additive packaging materials 2 which are further transported from the supply means 6 to a transfer means 8 from which the additive packaging materials 2 are picked up individually and one after the other. This pick-up of the additive packaging materials 2 is carried out at a low speed of the transfer means 8 or the additive packaging material 2. At other points, the additive packaging mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com