Composite sulfited vegetable oil leather fat-liquoring agent and method for preparing same

A technology of leather fatliquor and sulfitation, applied in leather impregnation, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve production process equipment investment High, affecting the quality of fatliquoring leather, and the product has peculiar smell, etc., to achieve good low temperature storage, long-term maintenance of fatliquoring effect, and good fatliquoring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

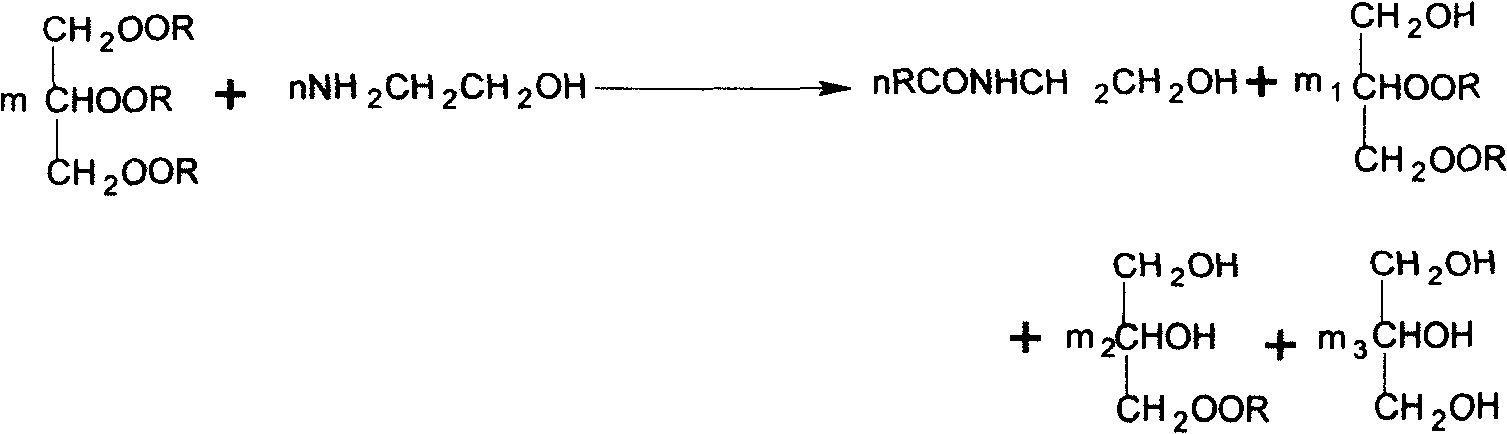

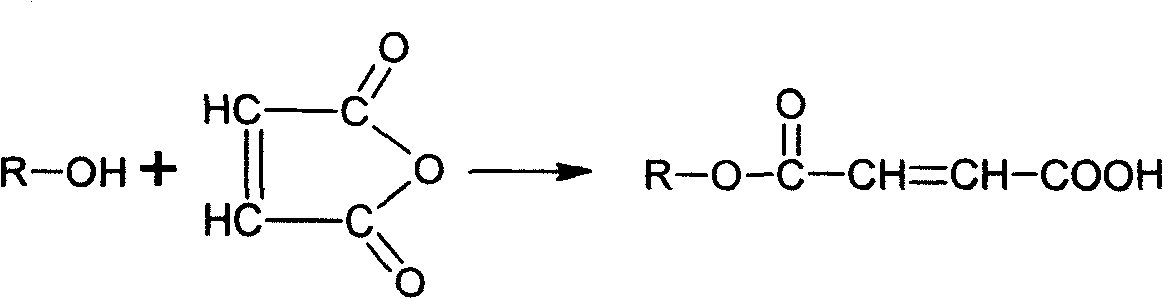

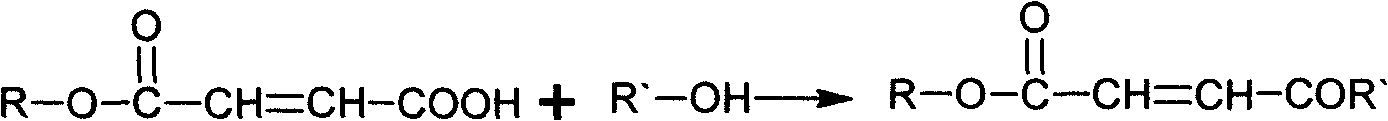

Method used

Image

Examples

Embodiment 1

[0037]Add 100.0 g of rapeseed oil and 7.0 g of monoethanolamine into a dry four-necked glass flask equipped with a stirrer and a condenser, and raise the temperature to 135° C. for amidation reaction. After the reaction is carried out for 2.5 hours, amidated rapeseed oil is obtained. The temperature of the system was lowered to 75° C., 22 g of maleic anhydride was added thereto, and then the temperature was raised to 95° C., and reacted for 3 hours to obtain amidated rapeseed oil succinic acid monoester. Then lower the temperature of the system to 80°C, install an oil-water separator on the reactor, add 41.5g of n-butanol and 0.85g of p-toluenesulfonic acid, raise the temperature to 130°C, reflux for 2-3 hours, and cool down after the theoretical amount of water is generated. to 120°C, distill off unreacted n-butanol under reduced pressure to obtain amidated rapeseed oil-n-butanol succinic acid diester. Then lower the system temperature to 70°C, add 89g of sodium bisulfite aqu...

Embodiment 2

[0039] Add 100.0 g of palm oil and 7.2 g of monoethanolamine into a dry four-necked glass flask equipped with a stirrer and a condenser, and raise the temperature to 135° C. for amidation reaction. After the reaction is carried out for 2.5 hours, amidated rapeseed oil is obtained. The temperature of the system was lowered to 75° C., 21.97 g of maleic anhydride was added thereto, and then the temperature was raised to 95° C., and reacted for 3 hours to obtain amidated palm oil succinic acid monoester. Then lower the temperature of the system to 80°C, install an oil-water separator on the reactor, add 41.5g of n-butanol and 0.9g of p-toluenesulfonic acid, raise the temperature to 130°C, reflux for 2-3 hours, and cool down after the theoretical amount of water is generated. To 120°C, distill off unreacted n-butanol under reduced pressure to obtain amidated palm oil-n-butanol succinic acid diester. Then lower the system temperature to 70°C, add 88g of sodium bisulfite aqueous solu...

Embodiment 3

[0041] Add 100.0 g of rapeseed oil and 9.0 g of monoethanolamine into a dry four-necked glass flask equipped with a stirrer and a condenser, and raise the temperature to 140° C. for amidation reaction. After the reaction is carried out for 2.5 hours, amidated rapeseed oil is obtained. The temperature of the system was lowered to 75° C., 27.47 g of maleic anhydride was added thereto, and then the temperature was raised to 95° C., and reacted for 3 hours to obtain amidated rapeseed oil succinic acid monoester. Then lower the temperature of the system to 80°C, install an oil-water separator on the reactor, add 51.86g of n-butanol and 0.94g of p-toluenesulfonic acid, raise the temperature to 130°C, reflux for 2-3 hours, and cool down after the theoretical amount of water is generated. to 120°C, distill off unreacted n-butanol under reduced pressure to obtain amidated rapeseed oil-n-butanol succinic acid diester. Then lower the system temperature to 70°C, add 111g of sodium bisulfi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com