A kind of modified phospholipid compound fatliquoring agent and preparation method thereof

A fatliquor and phospholipid technology, which is applied in the field of modified phospholipid compound fatliquor and its preparation, and achieves the effects of fine grain surface, good antioxidant capacity and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

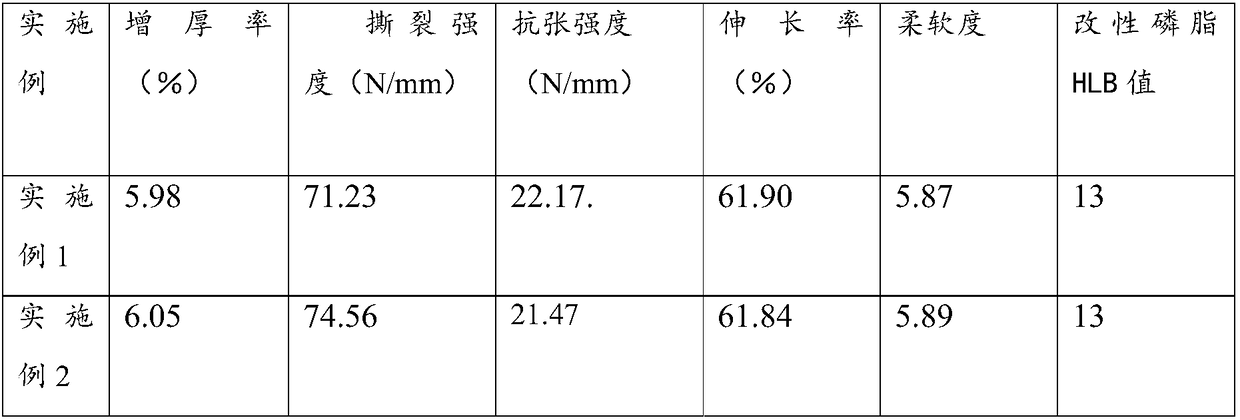

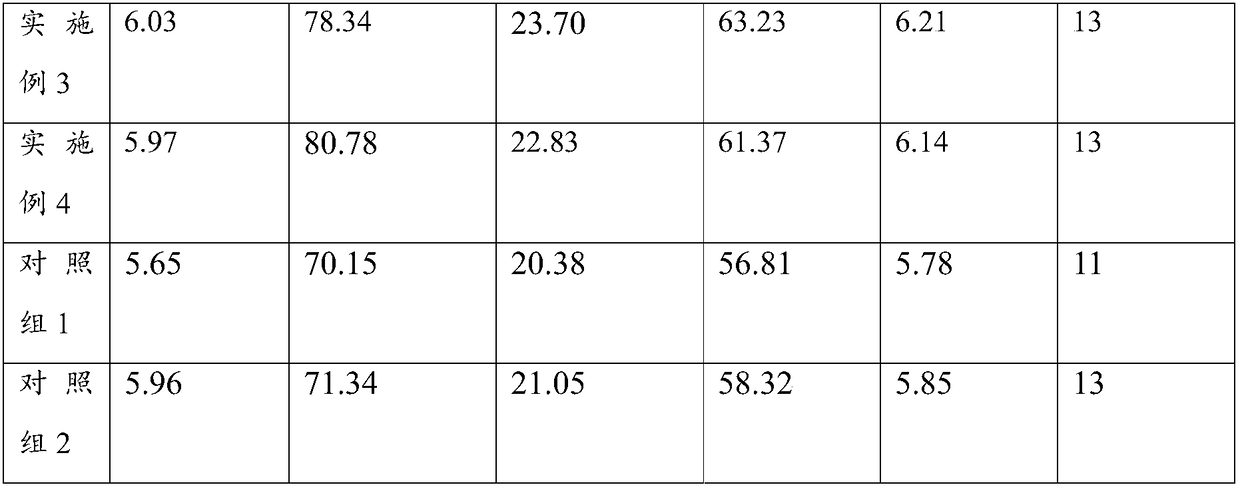

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of modified phospholipid composite fatliquor, comprising the following steps:

[0028] (1) preparing hydroxylated sulfated phospholipids;

[0029] (2) Compounding the hydroxylated sulfated phospholipids, surfactants, and inert oils prepared in step (1); it contains 30-60 parts of hydroxylated sulfated phospholipids, 50-90 parts of surfactants, and 50 parts of inert oils ~90 servings.

[0030] As mentioned above, the hydroxylated sulfated phospholipids need to undergo hydroxylation of the phospholipids and then sulfate the hydroxylated phospholipids. Obviously, the introduction of hydroxyl groups into the phospholipid molecules can improve the hydrophilicity of phospholipids, which can be moderately dispersed even in cold water, and the obtained products have a light color due to the bleaching effect of hydrogen peroxide.

[0031] It can be understood that although hydroxylated phospholipids have introduced hydrophili...

Embodiment 1

[0057] The preparation method of the modified phospholipid complex fatliquoring agent provided by the invention.

[0058] Hydroxylation of phospholipids: Add 50 parts of soybean lecithin and 1 part of lactic acid into a three-necked flask equipped with a stirring device, a thermometer and a condenser, stir and heat to 50°C, then drop 5 parts of hydrogen peroxide into the three-necked flask, drop After completion, react at a constant temperature of 50°C for 2h. After the reaction is completed, the moisture is removed in vacuum to obtain milky white syrupy hydroxylated phospholipids.

[0059] Sulfation of hydroxylated phospholipids: 60 parts of prepared hydroxylated phospholipids were put into a three-necked flask, and cooled with cold water (water temperature: 0° C.). At the same time, 4 parts of concentrated sulfuric acid was slowly added with a dropping funnel at a rate of 5 drops / min, and the temperature of the liquid was 25°C during the dropping. After the sulfuric acid w...

Embodiment 2

[0063] The preparation method of the modified phospholipid complex fatliquoring agent provided by the invention.

[0064] Hydroxylation of phospholipids: Add 50 parts of soybean lecithin and 6 parts of lactic acid into a three-necked flask equipped with a stirring device, a thermometer and a condenser, stir and heat to 75°C, then drop 10 parts of hydrogen peroxide into the three-necked flask, drop After completion, react at a constant temperature of 75°C for 4h. After the reaction is completed, the moisture is removed in vacuum to obtain milky white syrupy hydroxylated phospholipids.

[0065] Sulfation of hydroxylated phospholipids: 30 parts of hydroxylated soybean phospholipids were put into a three-necked bottle, and cooled with cold water (water temperature: 0°C). At the same time, 12 parts of concentrated sulfuric acid was slowly added with a dropping funnel at a rate of 8 drops / min, and the temperature of the liquid was 20°C during the dropping. After adding sulfuric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com