Graphene-poly ionic liquid composite material, and preparation method and application thereof

A technology of polyionic liquid and composite materials, which is applied in the field of graphene-polyionic liquid composite materials and its preparation, can solve the problems of affecting the detection sensitivity of electrochemical sensors, unstable performance of composite materials, and ionic liquid shedding, etc., and achieve the goal of reaction process Ease of control, increased electron transfer speed, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

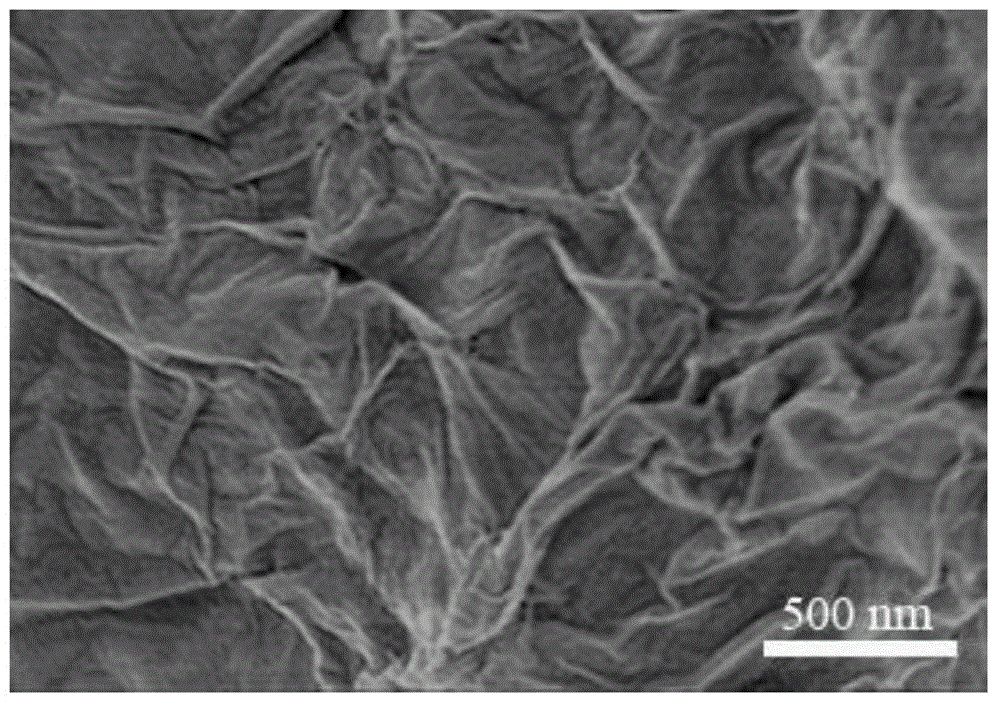

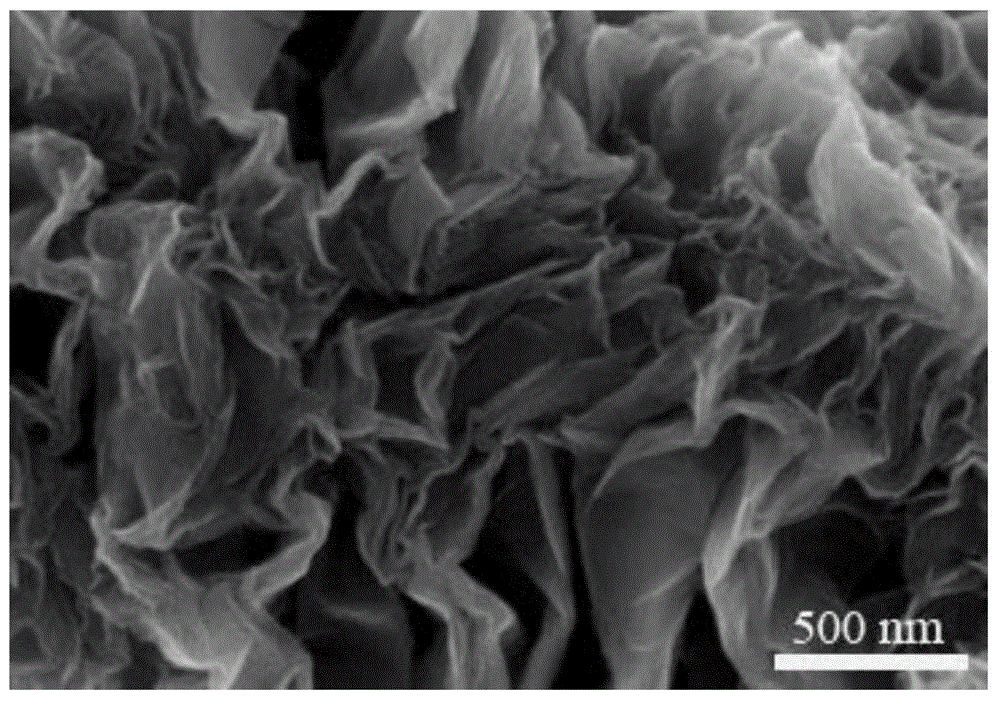

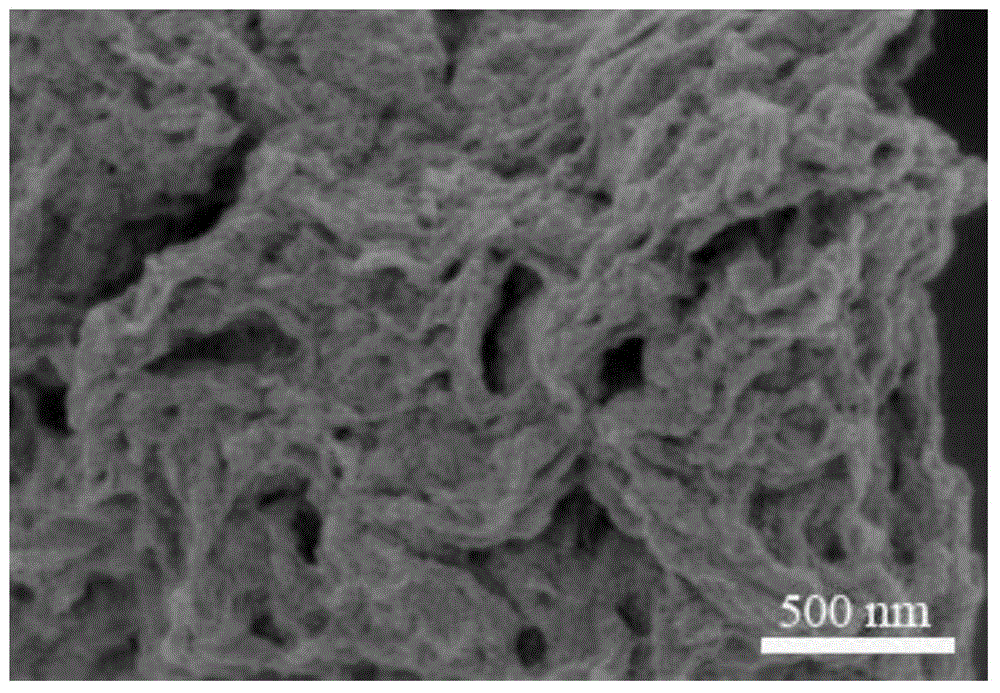

[0047] The preparation of embodiment 1 graphene-polyionic liquid composite material

[0048] 1. Synthesis of graphene oxide

[0049] Take 0.5g graphite powder, 0.5g NaNO 3 , 23mL concentrated H 2 SO 4 , added to a 250mL round bottom flask in turn, stirred in an ice bath for 60min; then slowly added 3g KMnO 4 After mixing evenly, stir in a 35°C oil bath for 2 hours; then, slowly add 40mL of water, and when the temperature rises to 95°C, stir for 30min; finally, slowly add 100mL of water, and then add 3mL of H 2 o 2 (30%), suction filtered, washed twice with 1M hydrochloric acid and water successively, and the filtrate was dried at 45°C to obtain graphene oxide (GO).

[0050] 2. Synthesis of graphene

[0051] Take 0.1g of graphene oxide and mix it into 200mL of water, after ultrasonication at 53KHz for 2h, add 100μL of 85% hydrazine hydrate and 1.4mL of 28% concentrated ammonia water, mix well, heat and stir at 95°C for 60min, then wash with water, and filter with suction ...

Embodiment 2

[0069] The preparation of embodiment 2 electrochemical sensors

[0070] 1. Preparation of GR-PIL modified electrode

[0071] (1) The glassy carbon electrode is made of Al 2 o 3 Powder suspension polishing, followed by ultrasonic cleaning with anhydrous ethanol and ultrapure water, the frequency of each ultrasonic cleaning is 53KHz, and the time is 5min; after the ultrasonic cleaning is completed, it is placed in the air to dry for use;

[0072] (2) Disperse 5mg of graphene-polyionic liquid composite material in 1mL of N,N-dimethylformamide (the concentration of GR-PIL is 5mg / mL), after ultrasonic mixing, take 5μL of the mixed solution and drop-coat it To the surface of the glassy carbon electrode, the RGI-PIL modified electrode is obtained after drying.

[0073] 2. Electrochemical behavior analysis of GR-PIL modified electrode on PEA

[0074] Dip the GR-PIL modified electrode into blank PBS and containing 1.0×10 -5M PEA in PBS (pH=0.05, 0.5M NaCl) solution was stirred and...

Embodiment 3

[0097] Example 3 Using GR-PIL Modified Electrode for Actual Sample Detection

[0098] In order to investigate the reliability of the GR-PIL modified electrode, the actual samples were tested.

[0099] For pig liver samples or pork samples, the pretreatment method is:

[0100] (1) Mix 1.0 g of ground pig liver sample or pork sample with 5 mL of ethyl acetate and 0.6 mL of 10% Na 2 CO 3 The solution was stirred and mixed, and then centrifuged at a speed of 3500r / min to collect the organic layer;

[0101] (2) repeat step (1) twice;

[0102] (3) Add 1 mL of 0.1M HCl to the collected organic layer, shake vigorously for 2 min, then centrifuge for 5 min, and collect the lower layer;

[0103] (4) Repeat step (3) twice to collect the extract;

[0104] (5) Dilute the extract to 10 mL with PBS buffer (pH 5.0); add PEA of a certain concentration before detection to prepare a spiked sample.

[0105] For the pig urine sample, the pretreatment method is as follows: centrifuge the pig u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com