Process for preparing biological diesel oil by using loop reactor

A loop reactor and biodiesel technology, which is applied in the preparation of biological raw materials, biofuels, and liquid hydrocarbon mixtures, etc., can solve the problems affecting the production cost and product quality of biodiesel, obvious wear of solid catalysts, and reduced product output and yield. problems, to achieve the effect of enhancing equipment operation flexibility, improving mass transfer and reaction efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

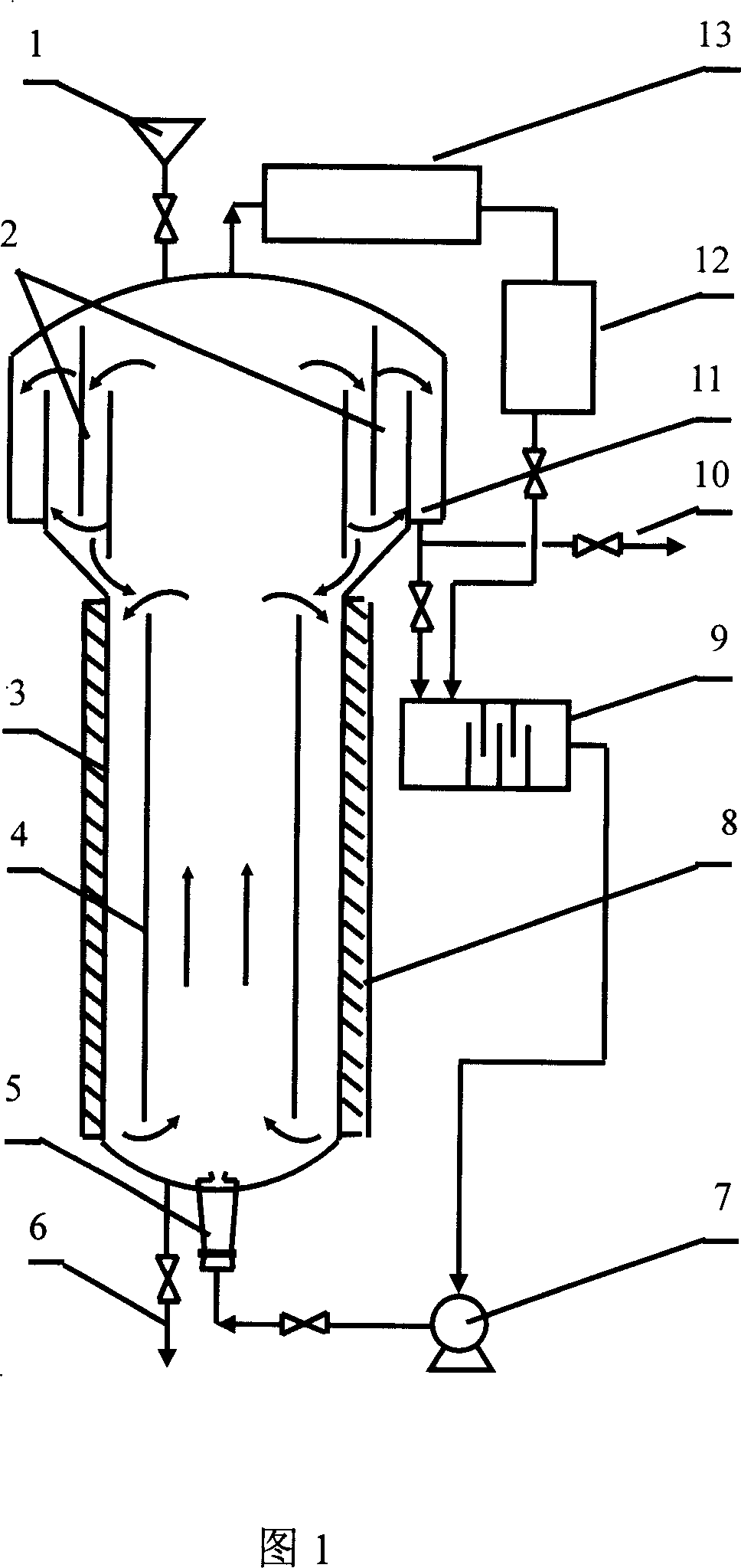

[0020] Mix 8kg of methanol and 15kg of edible rapeseed oil, and enter the above loop reactor through the pump and cavitation nozzle at a linear velocity of 20m / s, mix 150g of solid alkali catalyst KF / CaO with 0.5kg of methanol and add it to the loop through the feed port in the reactor. Slowly heat the loop reactor, maintain the temperature in the loop reactor at 60°C, pump the methanol in the header tank (via the static mixer) into the loop reactor until liquid overflows from the collecting tank into the static mixer, adjust appropriately The valve switch at the lower part of the head tank keeps the liquid level in the head tank basically constant. At this time, the mixture of methanol and rapeseed oil in the loop reactor is driven by the injection of the cavitation nozzle, vigorously mixed and moved upward in the draft tube, and forms a loop in the entire loop reactor, solid catalyst, methanol and rapeseed The oil is thoroughly mixed and transesterified in the loop reactor....

Embodiment 2

[0023] Mix 8kg methanol and 13kg edible soybean oil, and enter the above-mentioned loop reactor through the pump and cavitation nozzle at a linear velocity of 20m / s, and use hydrotalcite as the precursor to roast the solid alkali catalyst Mg-Al composite oxide 90g Mixed with 0.5 kg of methanol and fed into the loop reactor through the feed port. And repeat the experimental steps in Example 1, then cool down to room temperature for phase separation. The chromatographic detection of methyl ester content is 97.6%, the conversion rate of fatty acid methyl ester is 99.4%, and the yield is 99.5%; the glycerol content is 91.3%, and the yield is 96.2%.

Embodiment 3

[0025]Mix 8kg of methanol and 16kg of pretreated cottonseed oil, and enter the above-mentioned loop reactor through the pump and cavitation nozzle at a linear velocity of 20m / s, mix 160g of solid alkali catalyst MgO / CaO with 0.5kg of methanol and feed into the loop reactor. And repeat the experimental steps in Example 1, then cool down to room temperature for phase separation. The chromatographic detection of methyl ester content is 97.4%, the conversion rate of fatty acid methyl ester is 99.5%, and the yield reaches 96.5%; the glycerin content is 93.5%, and the yield is 94.5%.

[0026] The total height of the loop reactor is 0.7m, the shell diameter of the vapor-liquid-solid three-phase separator is 0.3m, the diameter of the cylindrical shell is 0.15m, the diameter of the guide tube is 0.1m, and the height of the guide tube is 0.35m. The loop reactor is effective The concrete embodiment that the loop reactor of liquid packing volume 10L produces biodiesel is as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com