Method for producing biodiesel by using tallowseed oil and special solid catalyst thereof

A biodiesel and catalyst technology, applied in physical/chemical process catalysts, biofuels, biological raw materials, etc., can solve the problems of high mechanical impurities, large acid consumption, affecting the use of products, etc., and achieve the effect of high activity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Preparation of magnetic nano-bifunctional solid acid and alkali catalyst

[0039] 1. The magnetic nano-bifunctional solid acid catalyst is prepared from the following compounds: sulfuric acid / zirconia-titania / ferric oxide (SO 4 2- / ZrO 2 -TiO 2 / Fe 3 o 4 ), sulfuric acid / γ-alumina-silicon dioxide / ferric oxide (SO 4 2- / γ-Al 2 o 3 -SiO 2 / Fe 3 o 4 ), sulfuric acid / aluminum trioxide-zirconia / ferric oxide (SO 4 2- / Al 2 o 3 -ZrO 2 / Fe 3 o 4 ), ammonium persulfate / titanium dioxide-zirconia / ferric oxide S 2 o 8 2- / TiO 2 -ZrO 2 / Fe 3 o 4 one or a combination of them.

[0040] The specific preparation process is described as follows:

[0041] (1) Magnetic matrix Fe 3 0 4 The preparation is calculated according to the amount of substance, FeCl 2 ·6H 2 O and FeCl 3 4H 2 O[n(Fe 3+ ):n(Fe 2+ )=2:1] into a three-necked bottle, placed in a constant temperature water bath at 65°C, stirred and simultaneously added dropwise ammonia water ...

Embodiment 2

[0061] Embodiment 2 Catalyst separation method

[0062] Get tallow tree seed oil (refined oil, acid value is less than or equal to 1.5mgKOH / g) 10kg, methanol 4kg, catalyst is KF / CaO / Fe 3 o 4 (the particle diameter of catalyzer is 50nm) 500g (catalyst consumption is 5% of Chinese tallow tree seed oil weight), described Chinese tallow tallow seed oil, catalyzer and methyl alcohol are placed in a reactor, and reaction temperature is 60 ℃, reacts under normal pressure After 3 to 4 hours, place the reactor on an electromagnet, turn on the power, and control the magnetic field strength to 0.1-0.8T (Tesla) by adjusting the current, and investigate the relationship between the recovery rate of the catalyst and the magnetic field strength. Figure 15 The relationship between the recovery of the catalyst and the strength of the magnetic field is shown, Figure 16 Shown is the relationship between the catalyst recovery rate and time when the magnetic field strength is 0.5T. from Fig...

Embodiment 3

[0063] Embodiment 3 utilizes Chinese tallow tree seed oil to produce biodiesel embodiment 1

[0064] Get tallow tree seed oil (refined oil, acid value is less than or equal to 1.5mgKOH / g) 10kg, methanol 4kg, catalyst is KF / CaO / Fe 3 o 4 (the particle diameter of catalyzer is 50nm) 300g (catalyst consumption is 3% of Chinese tallow tree seed oil weight), described Chinese tallow tallow seed oil, catalyzer and methyl alcohol are placed in a reactor, and reaction temperature is 60 ℃, reacts under normal pressure After 3 to 4 hours, the catalyst was separated by the method of Example 2, and the product was transferred to a separatory funnel for static separation to obtain biodiesel and by-product glycerol. In this embodiment, the conversion rate of biodiesel reaches over 97%, and the catalyst can be reused and regenerated after producing biodiesel.

[0065] The repetition and regeneration experiments of the catalytic base were carried out as follows:

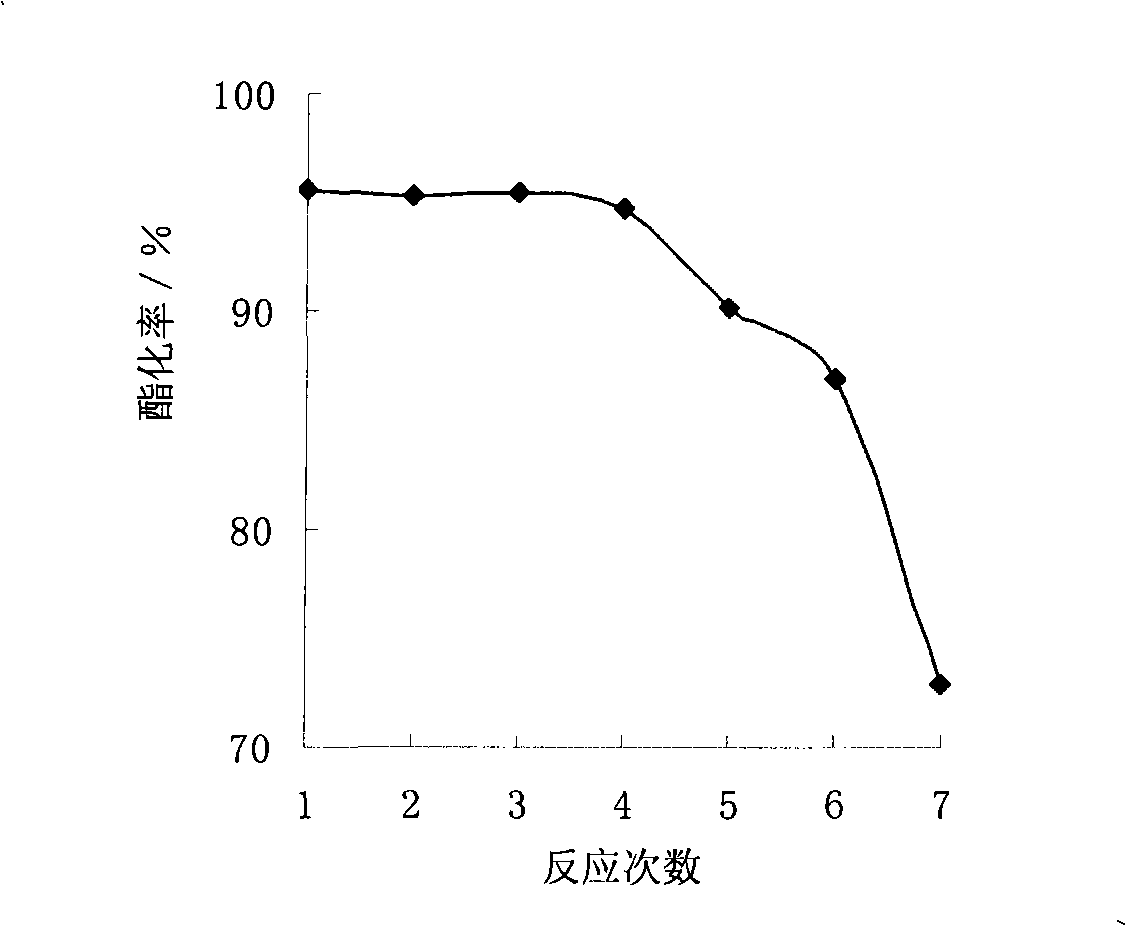

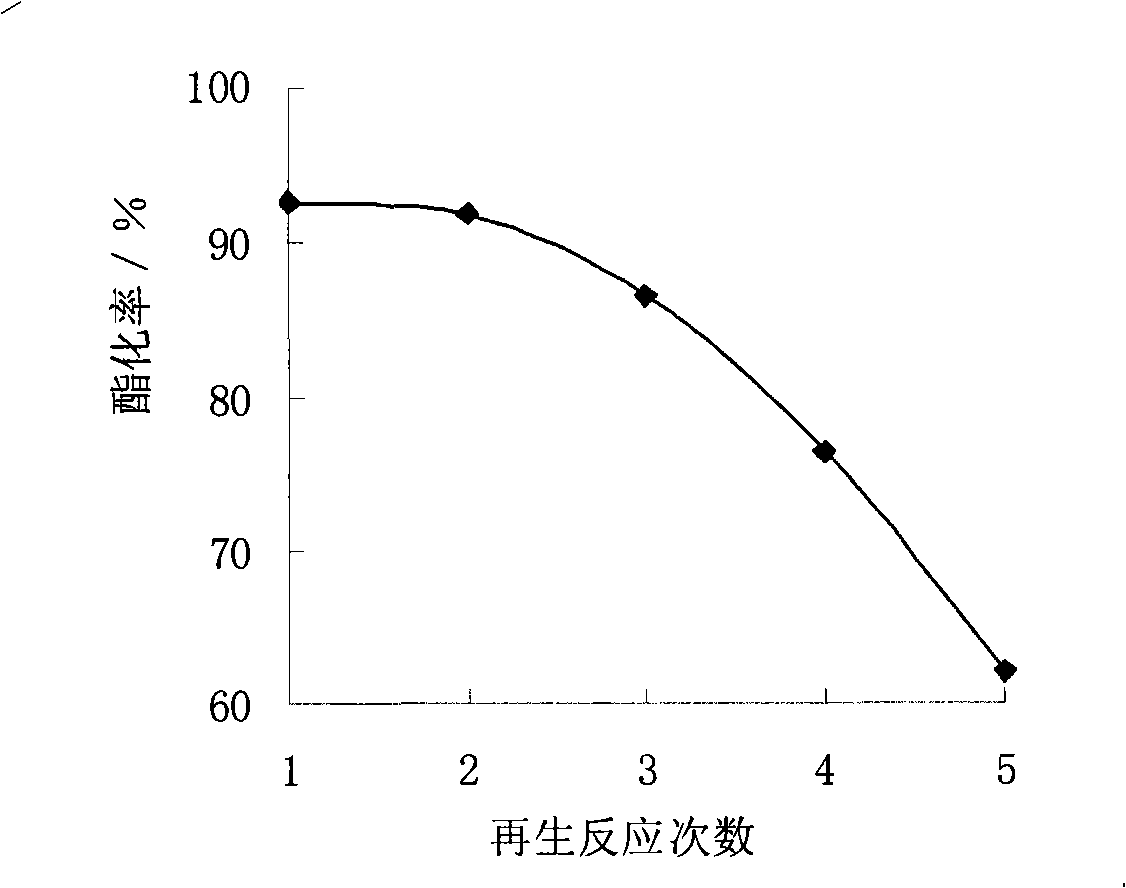

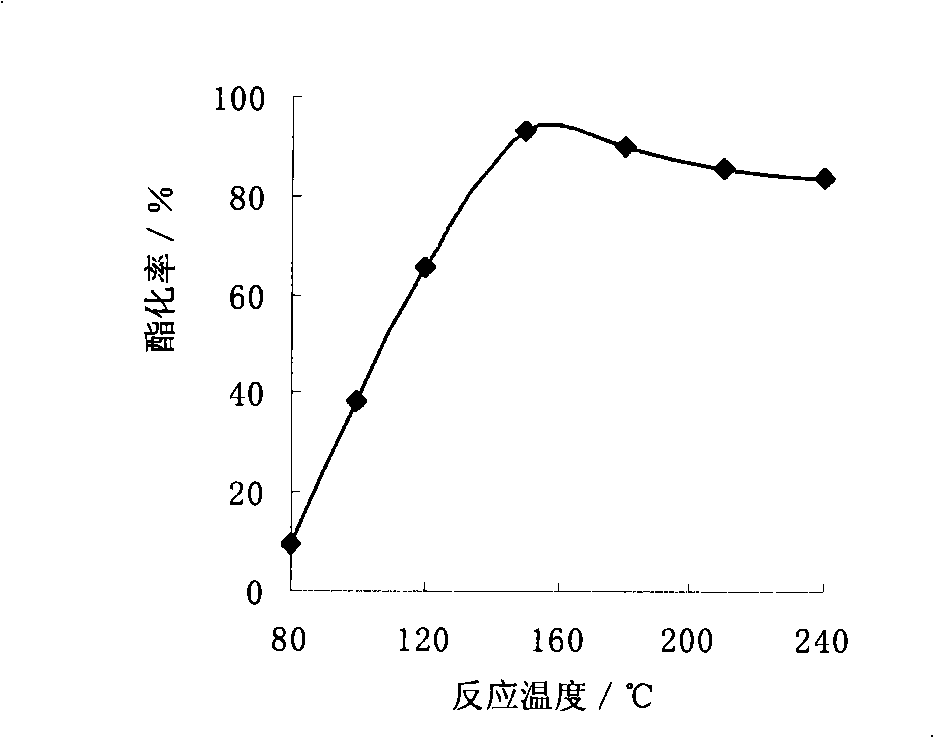

[0066] 1, the repeated exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com