Organic luminescent device and organic luminescence display apparatus

A technology for organic light-emitting devices and light-emitting displays, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc. Improve thermal conductivity and prevent overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

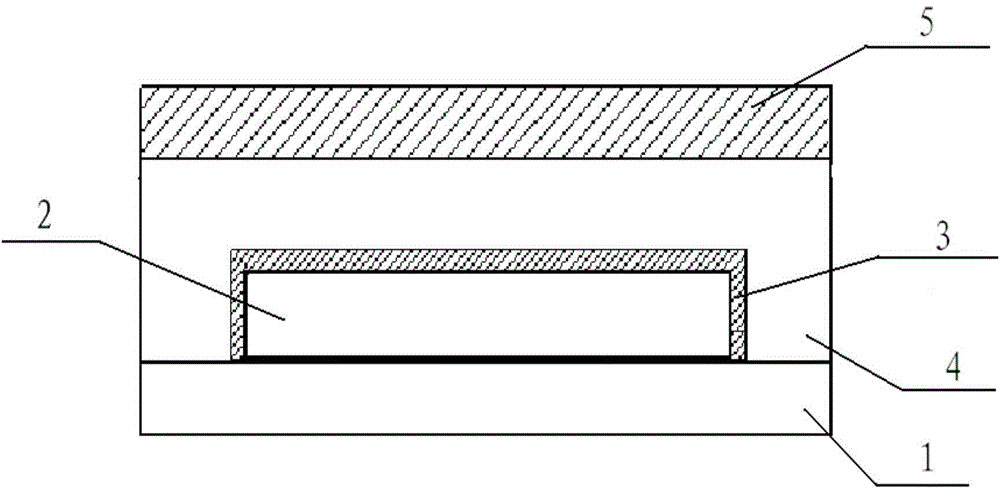

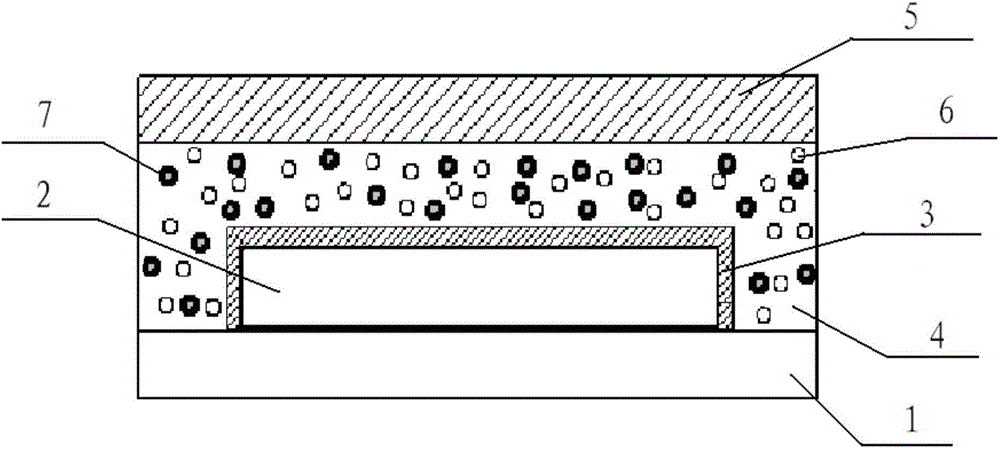

[0030] This embodiment provides a figure 2 The organic light-emitting device shown includes a substrate 1 and an organic light-emitting unit 2 disposed on the substrate 1;

[0031] Covering the passivation layer 3 of the organic light-emitting unit 2, the passivation layer 3 covers the organic light-emitting unit 2, and is used to block the influence of water and oxygen in the environment on the organic light-emitting unit 2;

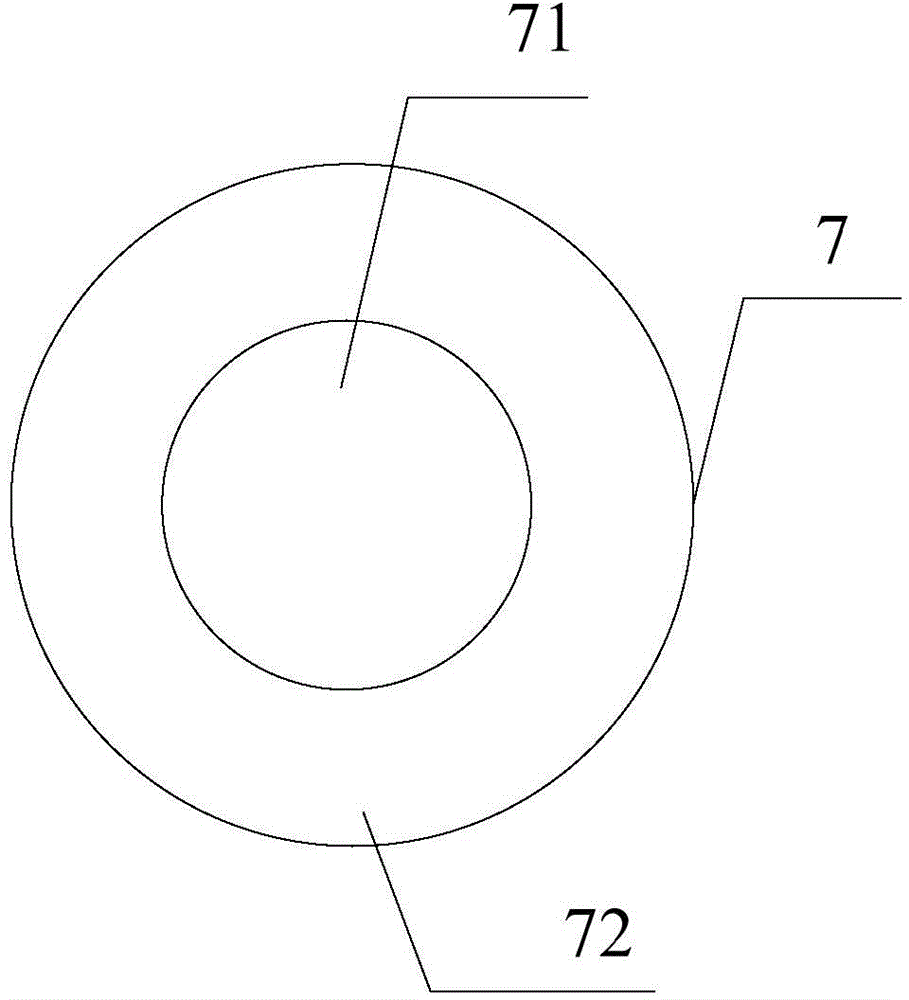

[0032] An encapsulation adhesive layer 4 is provided on the side of the passivation layer 3 away from the organic light-emitting unit 2, and a cover plate 5 is provided on the side of the encapsulation adhesive layer 4 away from the organic light-emitting unit 2, and the cover plate 5 is used as a heat sink. The heat generated by the organic light-emitting unit 2 is exported through the encapsulation adhesive layer 4 ; the encapsulation adhesive layer 4 includes heat-conducting particles 7 .

[0033] Since the encapsulating adhesive layer 4 in this em...

Embodiment 2

[0047] This embodiment provides a method for preparing the above-mentioned organic light-emitting device, including the following steps:

[0048] 1) Making an organic light-emitting unit

[0049]The necessary functional layers for light emission, such as the anode (indium tin oxide), the organic light-emitting layer, and the cathode, are fabricated on the substrate (glass substrate) by a known method. No more details here.

[0050] 2) Fabrication of passivation layer

[0051] In step 1, the organic light-emitting unit is covered with a passivation layer; the passivation layer can be made of Si 3 N 4 , SiO 2 , SiC, TiO 2 、Al 2 o 3 , ZnS, and ZnO; the passivation layer has the function of blocking water and oxygen; preferably, the thickness of the passivation layer is 500-1000nm. According to different materials, different known methods can be used to obtain the passivation layer, for example, chemical vapor deposition, sputtering, atomic force deposition, spraying, etc....

Embodiment 3-7

[0061] Embodiments 3-7 provide an organic light-emitting device prepared by the method described in embodiment 2, wherein the parameters of the main functional layers of the organic light-emitting device are shown in Table 1. It can be seen from Table 1 that the service life of the organic light-emitting device containing heat-conducting particles and desiccant particles in the encapsulating adhesive layer is extended to varying degrees compared with the organic light-emitting device not containing heat-conducting particles and desiccant particles in the encapsulating adhesive layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com