Spinner

A technology of spinning tools and spinning wheels, which is applied in the field of spinning tools and can solve problems such as uneconomical spinning equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

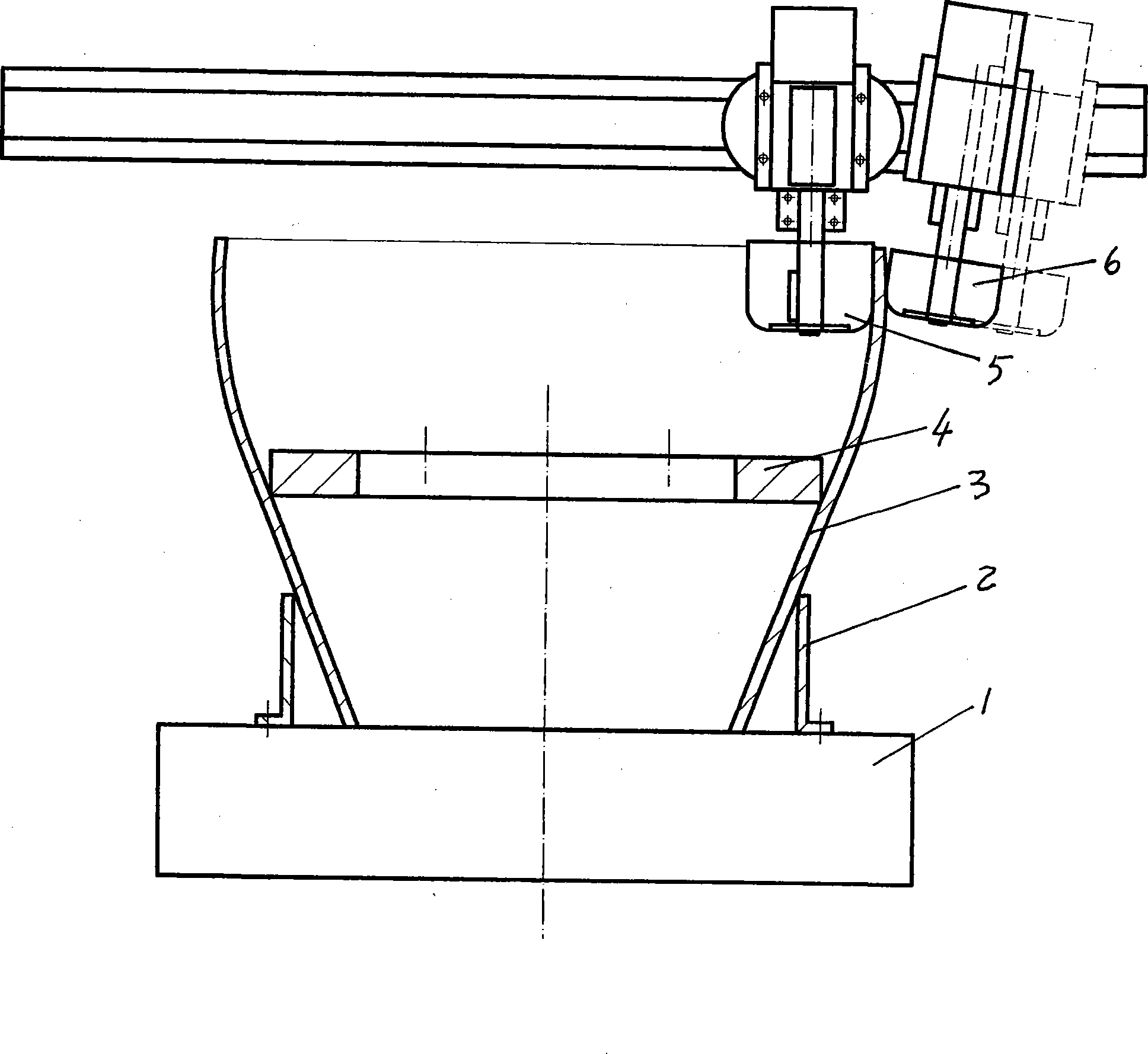

[0005] The present invention will be described in detail in conjunction with the above drawings. A vertical lathe workbench 1 is placed on a support cylinder 2 with an outer flange at the bottom, and its aperture is the same as the diameter of the middle of the conical cylinder. After being inverted in the support cylinder on the vertical lathe table 1, the support cylinder is fixed on the worktable with bolts. The circular pressure plate 4 in the conical cylinder is evenly distributed with threaded through holes along the circumference. The cylinder is pressed on the table. The main wheel 5 is placed in the upper port of the conical cylinder, and the thread on the upper end of the shaft matches the threaded hole on the lower surface of the tool holder of the vertical lathe. The spinning wheel 6 outside the upper port of the conical cylinder has its shaft. The thread on the upper end of the vertical lathe is matched with the threaded hole on the lower surface of another tool h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com