Tyre casting method and casting die

A technology of casting molds and casting models, which is applied in the direction of casting molding equipment, casting molds, and casting mold components, can solve the problems of low pass rate of ultrasonic flaw detection, high internal quality requirements of tires, and high production costs, etc., to achieve promotion Sequential solidification, no crack defects, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

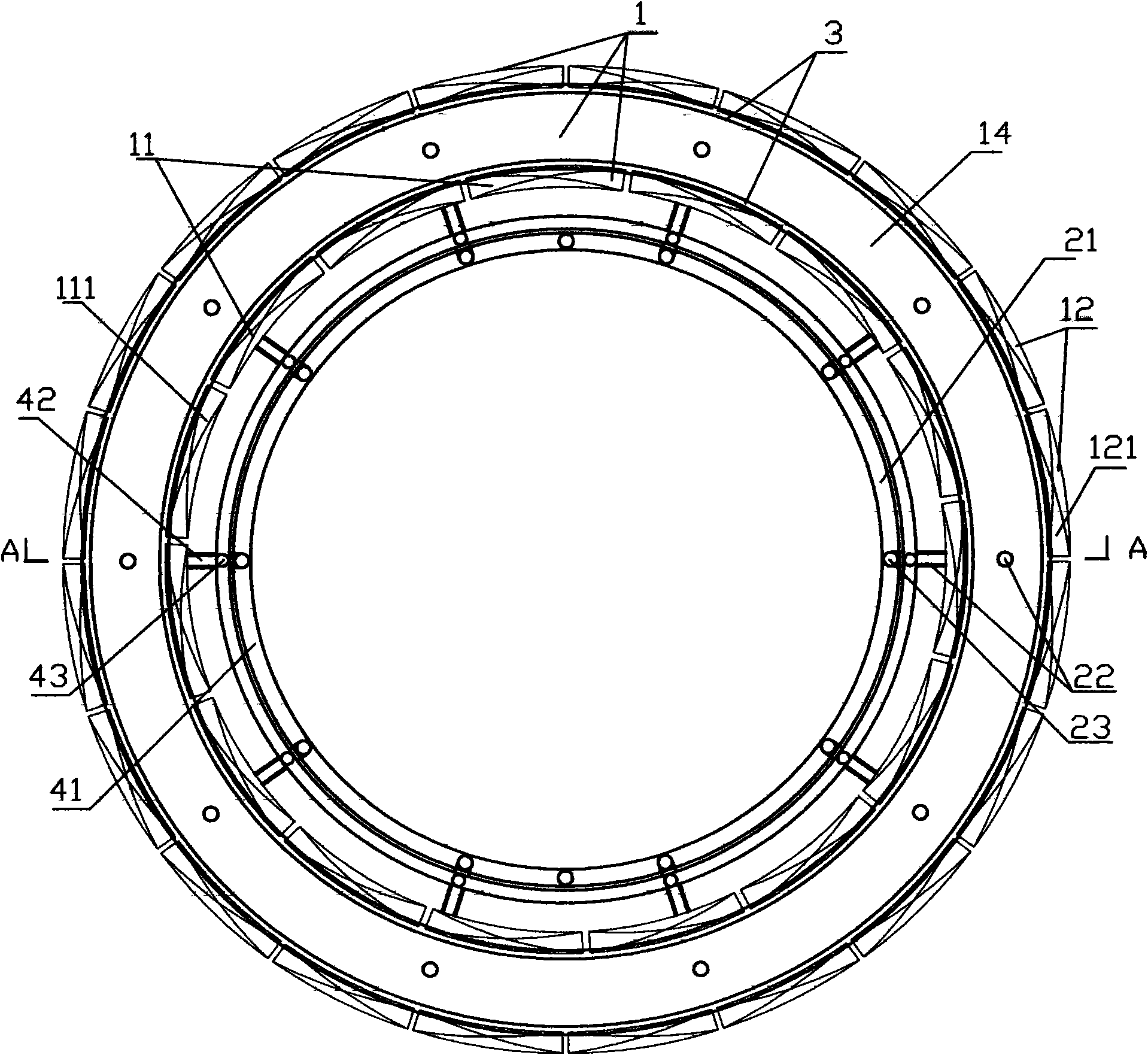

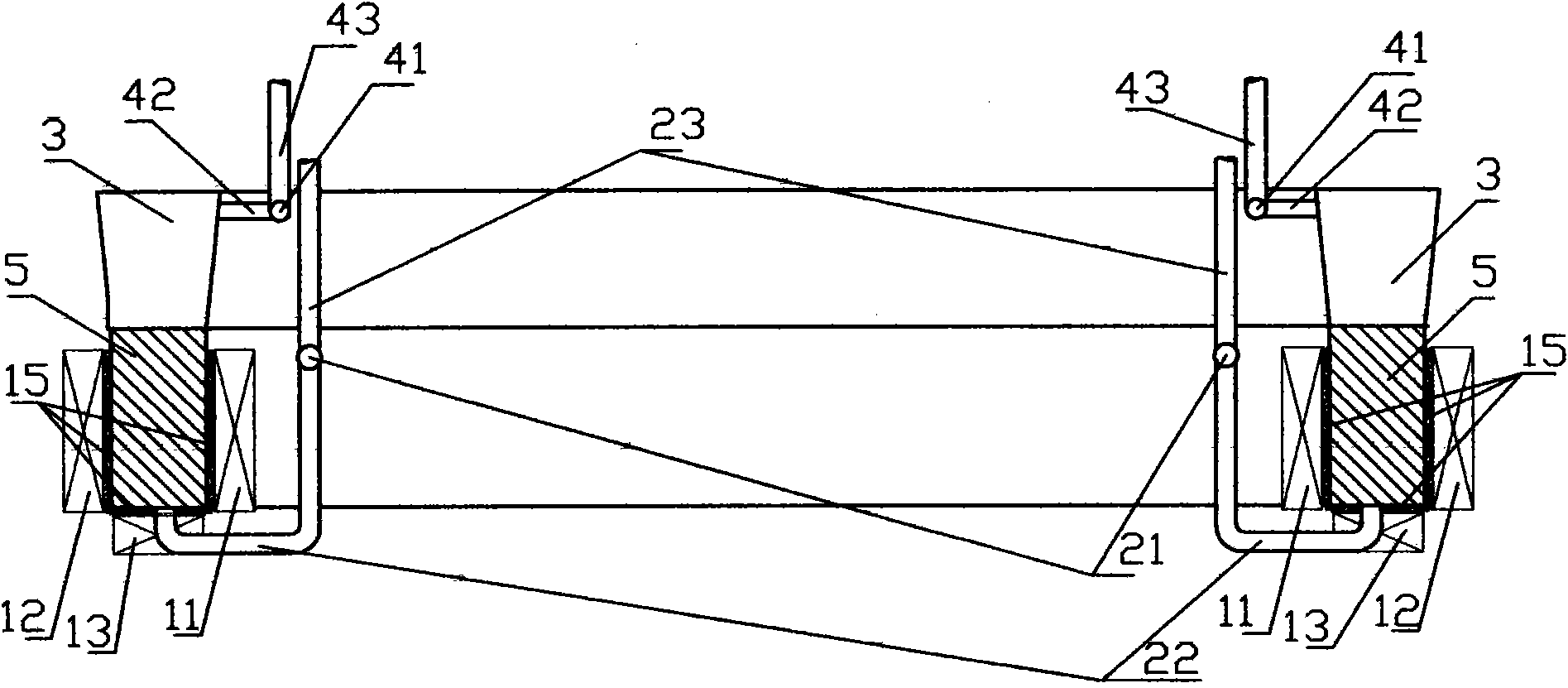

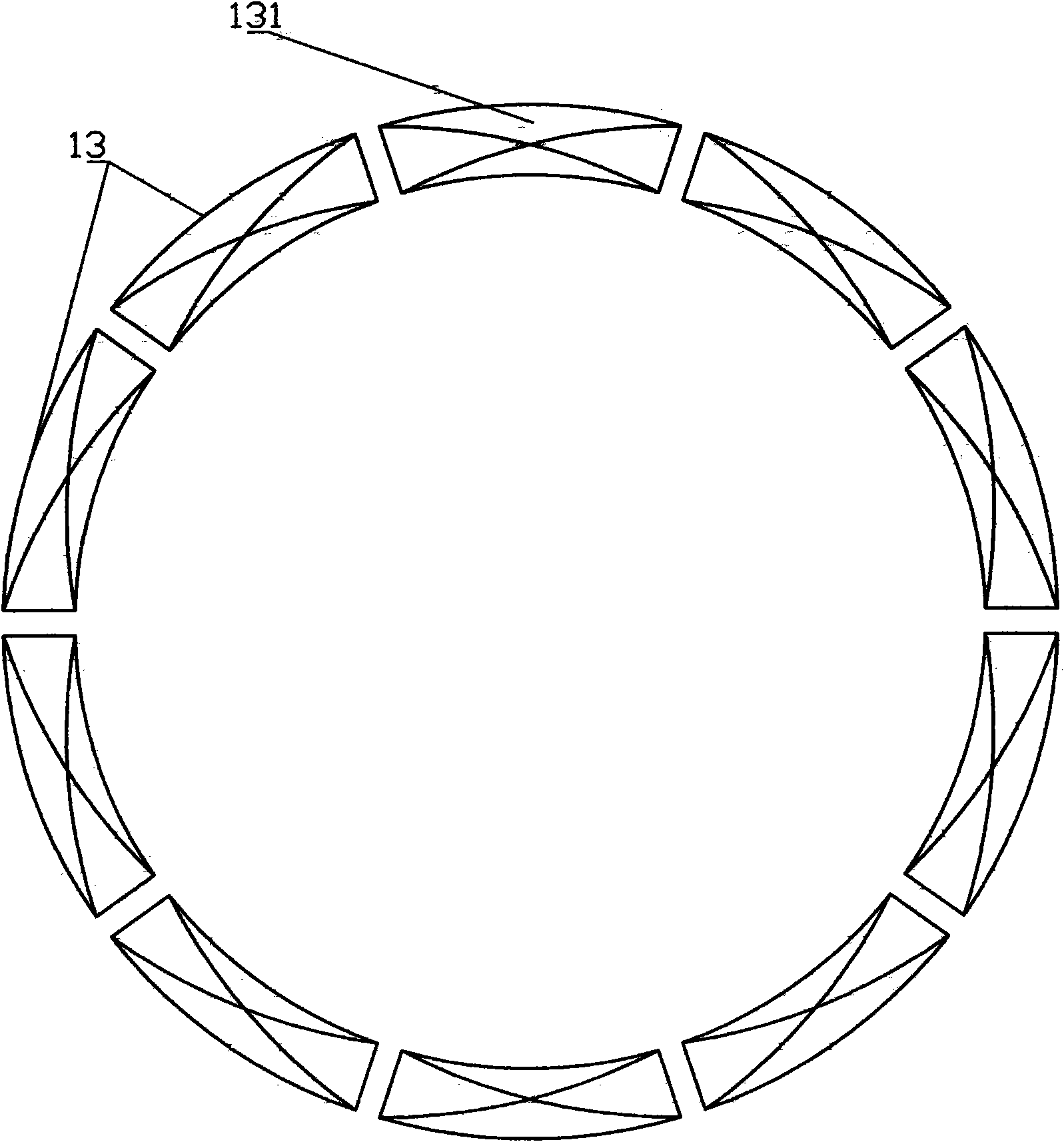

[0045] like Figure 1-3Shown, a kind of is used for tire casting mold, and it comprises annular slot mold 1, bottom pouring runner system, riser 3 and riser dotting pipeline system; Annular slot mold 1 is installed in the pit, It includes a ring-shaped inner wall 11, a ring-shaped outer wall 12 and a ring-shaped bottom pad 13, the ring-shaped inner wall 11 and the ring-shaped outer wall 12 are respectively located on the inner and outer sides of the ring-shaped bottom pad 13, and the ring-shaped inner wall 11. The annular outer wall 12 and the annular bottom pad 13 form an annular groove 14, the shape of the annular groove 14 is adapted to the shape of the tire 5 to be cast; the annular inner wall 11 is composed of fifteen It is surrounded by two fan-shaped inner wall blocks 111 with equal arc angles, that is, each fan-shaped inner wall block 111 is about one-fifteenth of a ring segment, and every two adjacent fan-shaped inner wall blocks 111 are separated by 45~ 60mm (mm is ...

Embodiment 2

[0069] The difference from Example 1 is that the material used in this example casting is ZG35CrMo, the liquidus temperature of this material is 1495°C, the pouring temperature is 1550°C, the size of the tire is φ6420×φ5470×1080, and the weight of the tire is 90900kg. The total weight is 151500kg; the height of the riser 3 is 800mm, the width is 554mm, and the taper of the riser is 1:10; other structural and method features are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com