Sand core structure of water turbine blade steel castings

A technology for water turbines and steel castings, applied in the field of casting, can solve the problems of high model cost, large sand-iron ratio, low production efficiency, etc., and achieve the effects of improving casting process efficiency, reducing sand-iron ratio and large plane size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

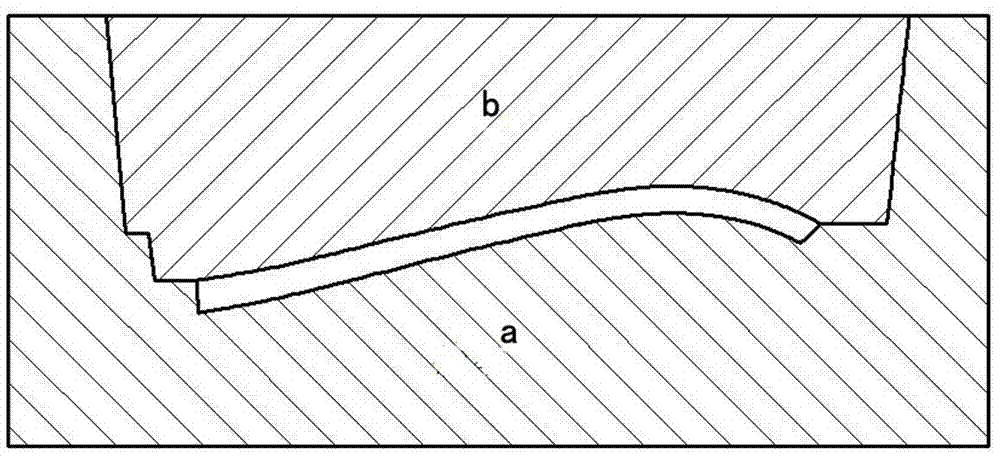

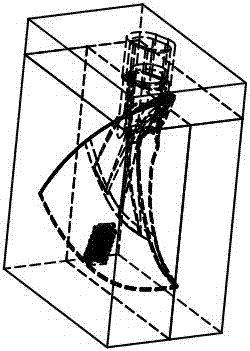

[0029] Such as image 3 — Figure 7 As shown, it is an embodiment of the sand core structure of the water turbine blade steel casting of the present invention, including several sand cores 8 that are sequentially assembled and combined along the straight line direction, such as Figure 4 and Figure 5 As shown, each adjacent sand core 8 is molded to form a casting cavity, and each sand core 8 is assembled and combined in sequence to form a plurality of casting cavities respectively, and the periphery of each adjacent sand core 8 cavity contour is provided with a matching The assembled core head 9 is provided with a positioning structure, each sand core shares a set of pouring system, and the top of the sand core 8 is respectively provided with a riser feeding structure.

[0030] In the sand mold structure arranged in a linear array in this embodiment, except for the sand cores located at the front and rear positions, the two sides of each sand core 8 in the middle position r...

Embodiment 2

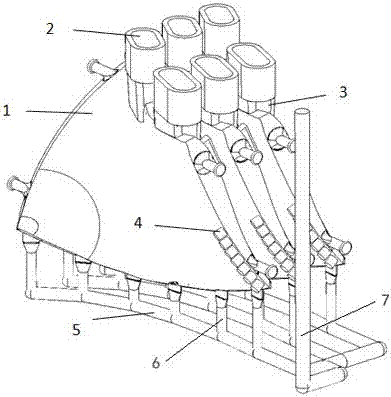

[0035] Such as Figure 8 Shown is the sand core structure of the water turbine blade steel castings of this embodiment that adopts the method of circular rotation array core assembly. The difference from the embodiment is that the sand cores of this embodiment are assembled sequentially along the circumferential direction to form a circular In the sand mold structure arranged in an array, the two sides of each sand core 8 also respectively form the front contour and reverse contour of the casting blade, and the circumference of the front contour and the reverse contour correspond to form the contour of the corresponding outer peripheral part of the blade. The matching and positioning structure of the head core between the sand cores is the same as that of the first embodiment, and the configuration of the pouring system and the riser feeding system is also similar to that of the first embodiment. The sand core structure of the circular rotating array of this structure can form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com