MEMS (Micro-Electromechanical System) sensor encapsulation structure and encapsulation method thereof

A packaging structure and packaging method technology, applied in the direction of microstructure devices, manufacturing microstructure devices, microstructure technology, etc., can solve problems such as difficult wiring, achieve strong scalability, compact overall device structure, and easy wiring layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

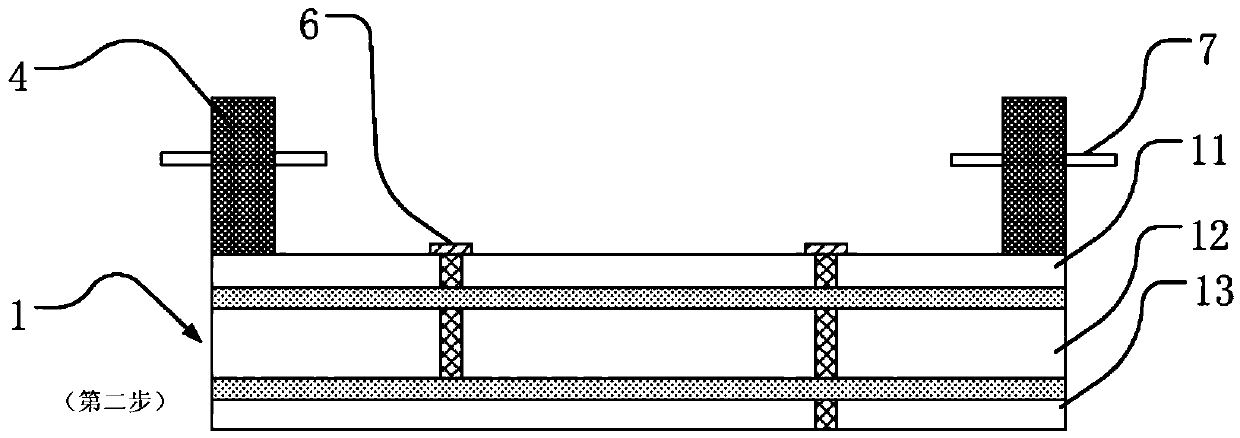

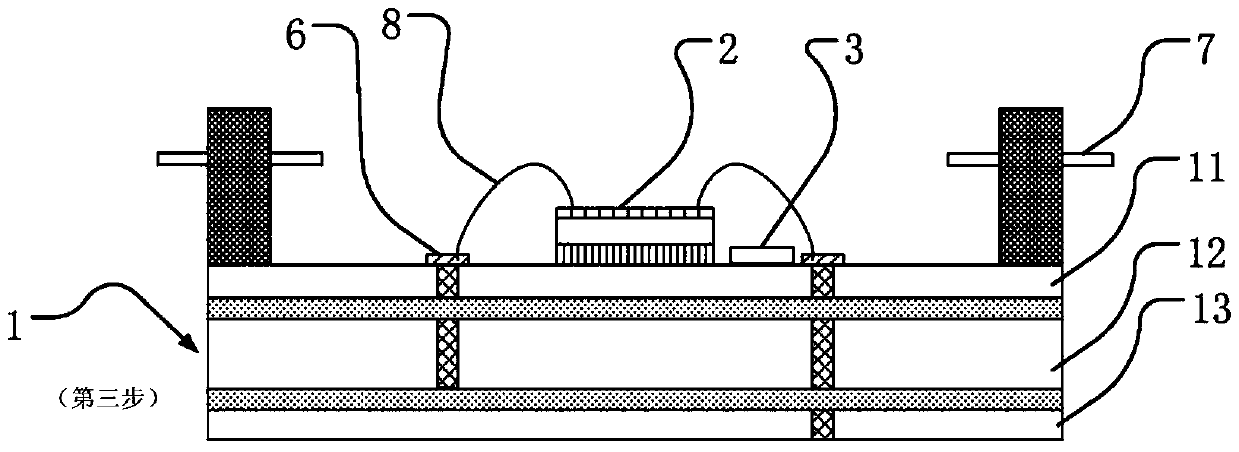

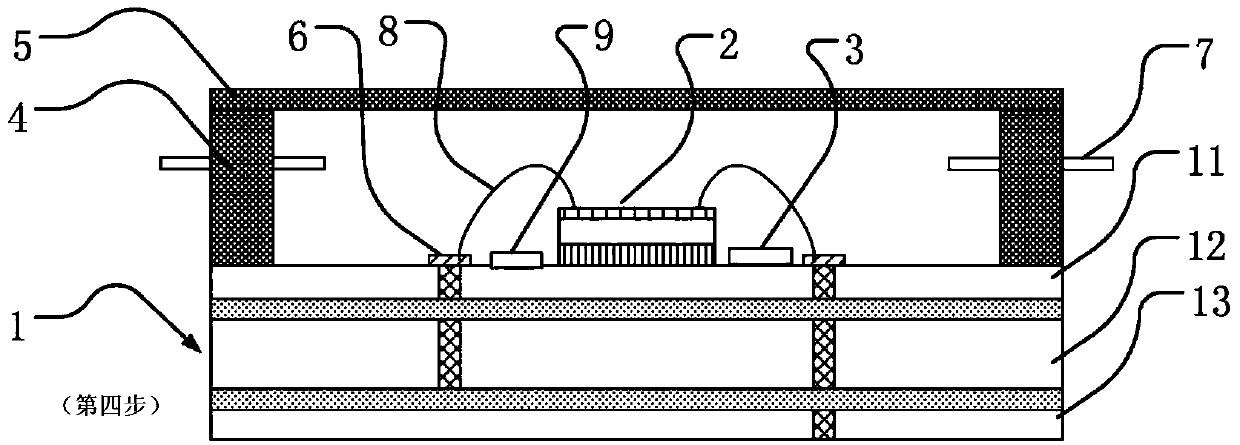

[0037] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

[0038] Based on the use environment of the product of the present invention, long-term outdoor operation is required, which brings severe challenges to the airtightness of the accelerometer packaging process, harsh environments such as high temperature and high humidity, and packaging stress.

[0039] refer to Figure 1 to Figure 8 , the present invention provides a MEMS sensor packaging structure, which is used to package MEMS sensors, the packaging structure comprising:

[0040] A ceramic base 1, the top layer 11 and the bottom layer 13 of the ceramic base 1 are respectively provided with a plurality of metal pads 6; the metal pads 6 of the top layer 11 of the ceramic base are connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com