Antifouling coating composition, antifouling coating film formed from the composition, coated object having the coating film on surface, and method of antifouling by forming the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

production example 1

Production of Copolymer Solution (A); S-1

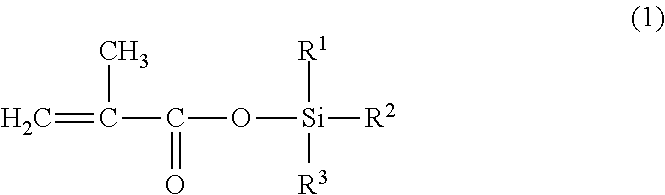

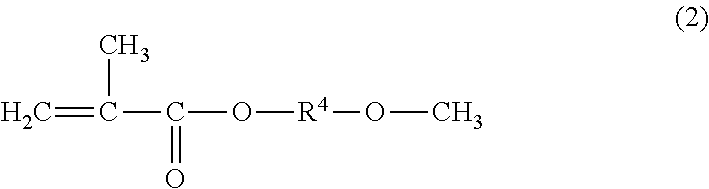

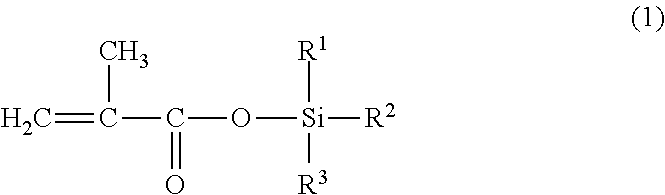

[0136]230 g of xylene was charged to a 1,000 ml flask equipped with a thermometer, a reflux condenser, a stirrer, and a dropping funnel, after which a mixture of 230 g of triisopropylsilyl methacrylate, 210 g of methoxyethyl methacrylate, 30 g of methyl methacrylate, 30 g of ethyl acrylate, and 4 g of t-butyl peroxy-2-ethyl hexanoate (initially added) was added dropwise into the flask over a period of 1 hour, while stirring at 100±2 deg. C. in a nitrogen atmosphere. After the dropwise addition, the polymerization reaction was performed for 2 hours at 100±2 deg. C. Then, while stirring the resulting reaction solution at 100±2 deg. C., 1 g of t-butyl peroxy-2-ethyl hexanoate (subsequently added) was added three times with 2-hour intervals to perform the polymerization reaction. After that, 270 g of xylene (additional solvent) was added and dissolved, thus producing the triorganosilyl ester-containing copolymer solution S-1. Table 1 shows the vi...

production examples 2 to 6

and Comparative Production Examples 1 to 4

Production of Copolymer Solutions S-2 to 6 and Comparative Copolymer Solutions H-1 to 4

[0137]Polymerization reactions were performed according to the same procedure as Production Example 1, using the organic solvent, monomers, and polymerization initiator shown in Table 1, thus producing the triorganosilyl ester-containing copolymer solutions S-2 to 6, and the comparative copolymer solutions H-1 to 4. Table 1 shows the viscosity, non-volatile content, Mw, and Tg of each copolymer solution obtained.

TABLE 1Production ExampleComparative Production ExampleIngredient ClassIngredient Name1234561234Solvent In Initial ContainerXylene230230230230230230230230230230Triorgano-Meth-Triisopropylsilyl230250270300270silylacrylateMethacrylateGroup-(MonomerT-Butyldiphenylsilyl250300270Containing(a))MethacrylateMonomerAcrylateTriisopropylsilyl270AcrylateT-Butyldiphenylsilyl270AcrylateMethoxyalkyl Methacrylate2-Methoxyethyl210190170150210160303050(Monomer (b))M...

production example 7

Production of Gum Rosin Copper Salt

[0138]400 g of a xylene solution of gum rosin (solid content: 50%); 200 g of cuprous oxide, and 100 g of methanol were added, together with glass beads (diameter: 2.5 to 3.5 mm), to a 1,000 ml flask equipped with a thermometer, a reflux condenser, and a stirrer, and the mixture was stirred for 8 hours at 70 to 80 deg. C. and then maintained for 2 days at 50 deg. C. The resulting mixture was cooled to room temperature (25 deg. C.) and filtered, and subsequently concentrated under reduced pressure to remove the methanol by distillation. Xylene was then added to the obtained concentrate, thus producing a xylene solution of gum rosin copper salt (a transparent dark blue solution; solid content: about 50%). The resulting xylene solution of gum rosin copper salt had a non-volatile content of 50.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com