Filling up Teflon friction ring and its preparing method

A polytetrafluoroethylene and manufacturing process technology, applied in the field of friction rings, can solve the problems of short service life of friction rings and damage to the wear surface, and achieve improved service life, good cold flow resistance and wear resistance, and good self-lubrication. and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

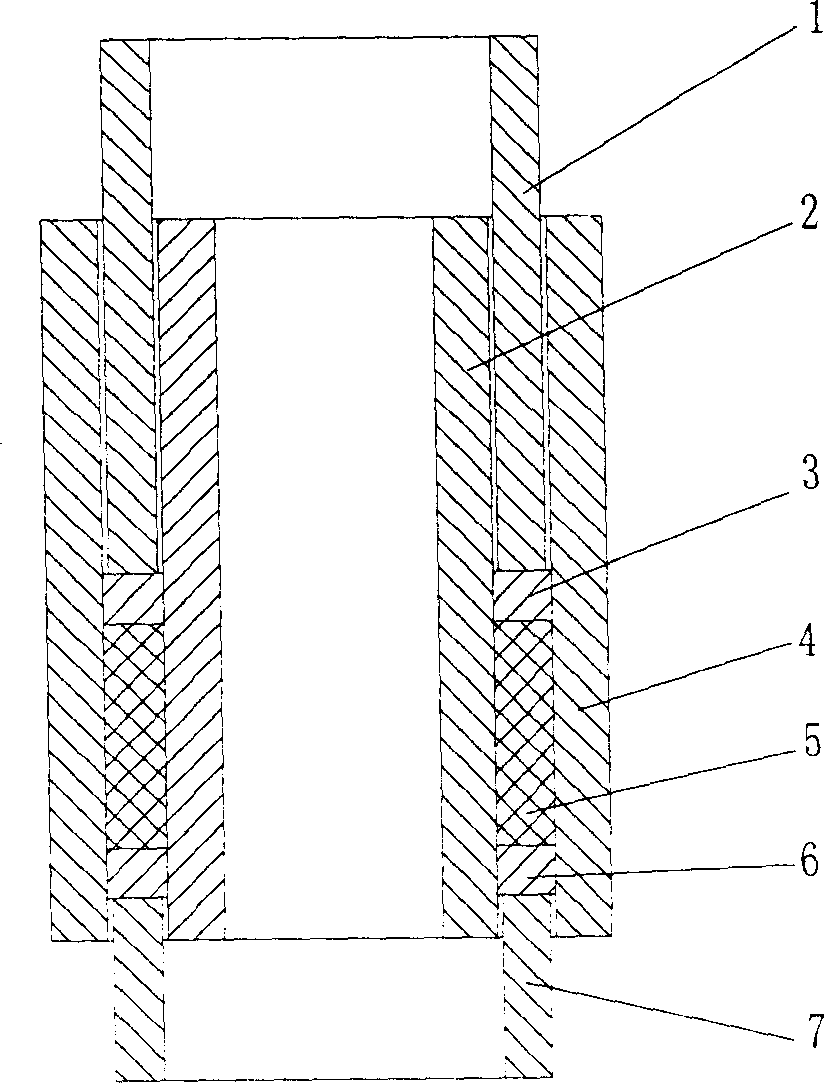

[0038] This filled PTFE friction ring is a friction ring used in a 4MPa reciprocating oil-free lubrication compressor. The specific working conditions are as follows: bore: 90mm, pressure: 4MPa, stroke: 180mm, operating temperature: ≤180℃, Medium: air, reciprocating frequency: 585min -1 ; The specific structure of the filled polytetrafluoroethylene friction ring is as follows Figure 5 ~ Figure 7 shown by Figure 5 ~ Figure 7 It can be seen that a shallow groove at a certain angle to the axis of the cylinder is machined on the outer circle and end surface of the friction ring. This groove can reduce the axial load of the friction ring. The herringbone shallow groove can make the torque formed by the axial force cancel each other out. Under the action of the torque formed by the oblique opening, the friction ring can rotate slowly along the circumferential direction, so as to achieve the purpose of uniform wear.

[0039] The type selection, composition and ratio of the filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com