Copper clad laminate and impregnation liquid for making same

A copper foil substrate and immersion technology, which is applied to the copper foil substrate and the immersion liquid used to make the copper foil substrate, can solve the problems of increased drill loss, increased defect rate, and more dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

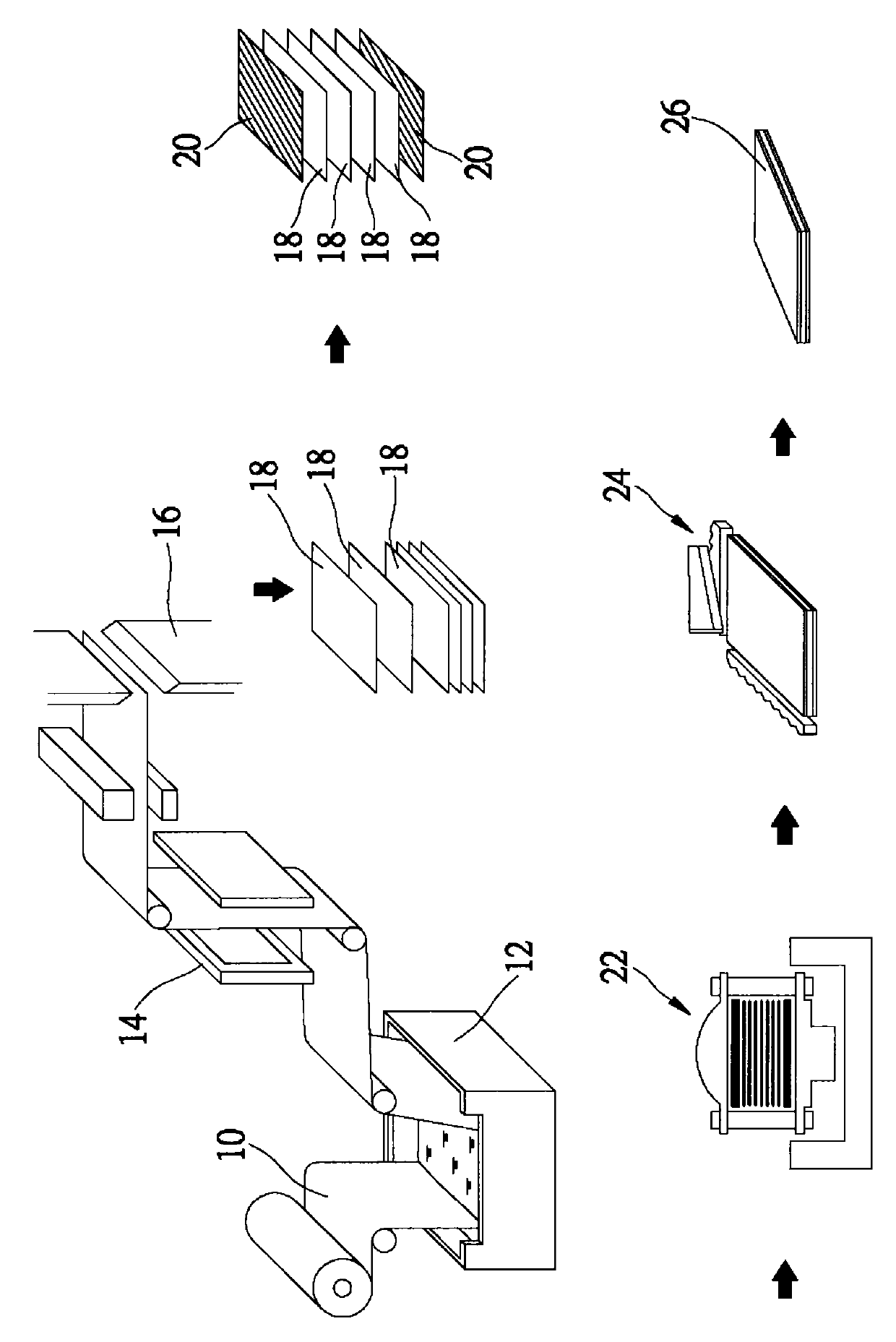

[0018] figure 1 It shows a general process for manufacturing glass fiber copper foil substrates, which includes: sending glass fiber cloth 10 into an impregnation tank 12 containing impregnation liquid. After being heated by a heater 14, it is cut to a predetermined size with a cutter 16 to form several prepregs 18 for future use. Next, a predetermined number of prepregs 18 are stacked together with a predetermined fiber direction, and a copper foil 20 is respectively arranged on the top surface and the bottom surface, and the hot-molded sheet 22 is performed. After the hot-molded plate is properly trimmed 24, a copper foil substrate 26 with a glass fiber substrate in the center and copper foil on both sides can be obtained. The overall structure of the copper foil substrate 26 is composed of a plurality of prepregs 18 and It is composed of at least one copper foil 20, and each of the prepregs 18 is composed of glass fiber cloth 10 and impregnated material (after the impregna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com