Photocrosslinkable polyrotaxane, composition comprising the photocrosslinkable polyrotaxane, crosslinked body derived from the composition, and methods for producing same

A technology of photocrosslinking and polyrotaxane, applied in the field of crosslinkers, can solve the problem of low degree of modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

[0223] The present invention will be described in further detail below based on the examples, but the present invention is not limited by the examples.

Embodiment 1

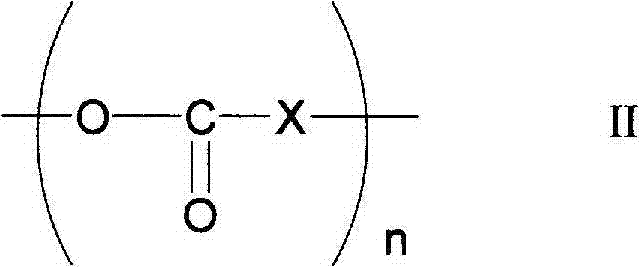

[0225] According to the method described in WO2005-080469 (wherein, the content of this document is incorporated in this specification as a reference), the linear molecule: polyethylene glycol (average molecular weight: 35,000), the cyclic molecule: α-cyclogluter fine (hereinafter referred to as "cyclodextrin" as "CD"), capping group: a compound obtained by further hydroxypropylation of polyrotaxane formed by adamantine group (hereinafter referred to as hydroxypropylated polyrotaxane "HAPR35") (α-CD inclusion ratio: 25%; hydroxypropyl modification ratio: 50%; theoretical hydroxyl group amount: 9.7 mmol / g; weight average molecular weight Mw based on gel permeation chromatography (GPC): 150000). The measurement of molecular weight and molecular weight distribution was carried out with a TOSOHHLC-8220GPC device. Chromatographic column: TSK guard column Super AW-H and TSKgel Super AWM-H (two connected), eluent: dimethyl sulfoxide / 0.01MLiBr, column temperature: 50°C, flow rate: 0.5...

Embodiment 2

[0232] Except that 21.5 g of ε-caprolactone and 1.0 g of α-methyl-γ-butyrolactone were used instead of 22.5 g of ε-caprolactone in of Example 1, the same operation was carried out as in Example 1 to produce a modified polymer Rotaxane A-2. As measured by GPC, the weight average molecular weight Mw of the obtained polyrotaxane was 580,000.

[0233] The degree of polymerization of the copolymer of ε-caprolactone and α-methyl-γ-butyrolactone was investigated by the amount of theoretical hydroxyl groups of the raw material HAPR35 and the monomer consumption of gas chromatography (GC) (almost 100%). As a result, it was found that, The degree of polymerization of the obtained modified polyrotaxane A-2 was 4.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

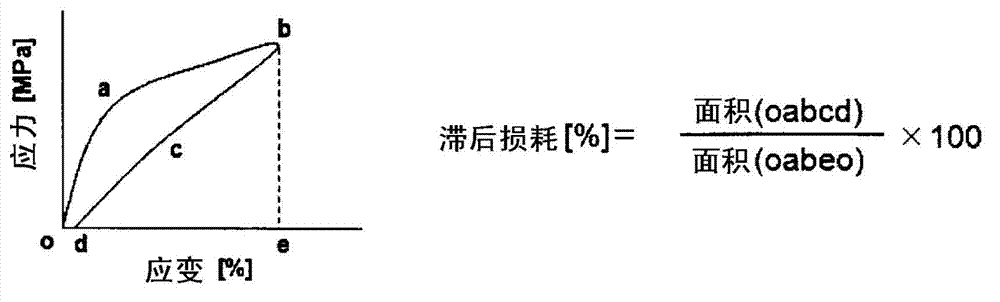

| hysteresis loss | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com