Ultra high molecular weight polyethylene and polyvinyl chloride composite pipe embedded with reinforced steel filaments and manufacturing method thereof

An ultra-high molecular weight, polyethylene pipe technology, applied in the direction of pipes/pipe joints/pipes, pipes, rigid pipes, etc., can solve the problems of difficult continuous production, and achieve simple manufacturing process, high composite strength and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

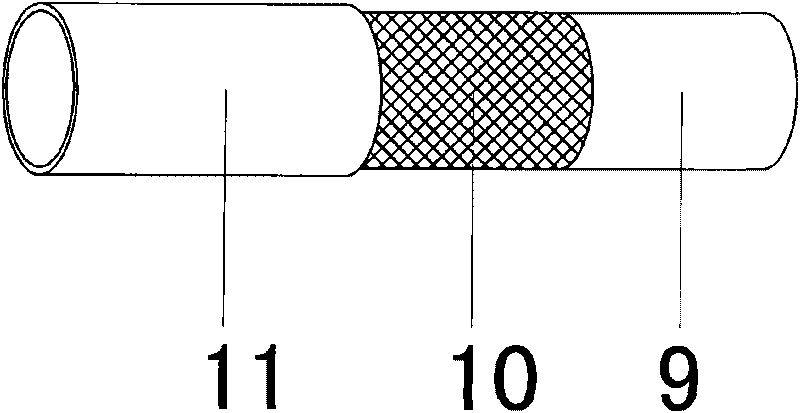

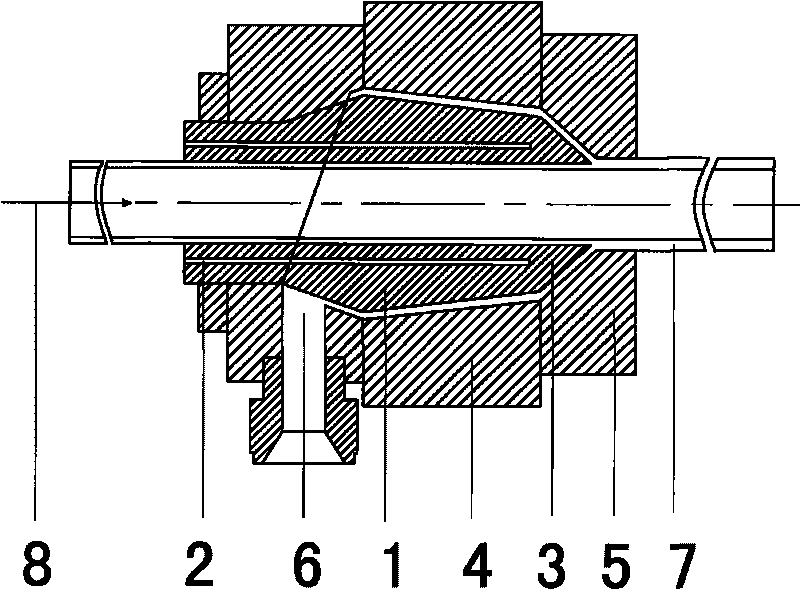

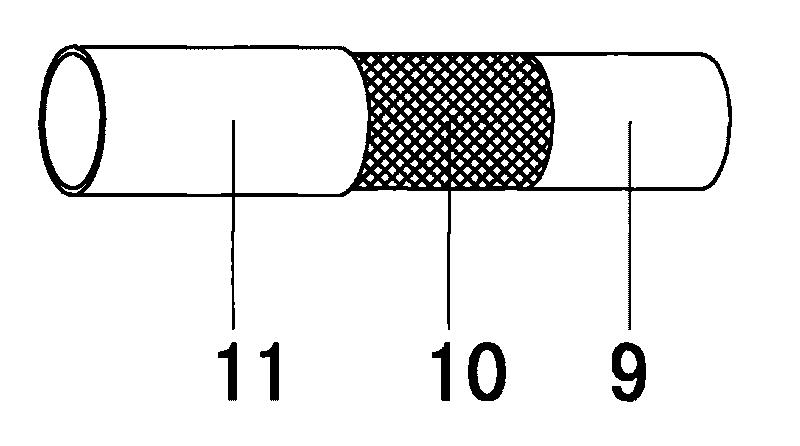

[0042] Example 1 Manufacture of ultra-high molecular weight polyethylene polyvinyl chloride composite pipe with embedded reinforcing steel wire of φ110×10mm

[0043] Including the following steps:

[0044] a. Embedded reinforced steel wire

[0045] A steel wire with a diameter of 0.8mm is wound on the outer wall of a commercially available φ100*5mm ultra-high molecular weight polyethylene pipe with a steel wire winding machine, the steel wire and the pipe axis are at 45°, and the distance between the steel wires is 3.0mm. The steel wire is heated to 180°C-200°C by means of high-frequency induction heating, so that the ultra-high molecular weight polyethylene on the outer wall is partially melted, and half of the diameter of the steel wire is embedded on the outer wall of the ultra-high molecular weight polyethylene pipe.

[0046] b. The compounding of the ultra-high molecular weight polyethylene inner tube embedded with reinforced steel wire and the outer wall of polyvinyl ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com