Carbon fiber reinforcing tyre casting gypsum powder and preparation method thereof

A tire casting and carbon fiber technology, which is applied in the field of carbon fiber reinforced tire casting gypsum powder and its preparation, can solve the problems of decreased mechanical properties, poor thermal conductivity, variability of castings, etc., and achieves improved physical and chemical properties. The preparation method is simple, and the production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

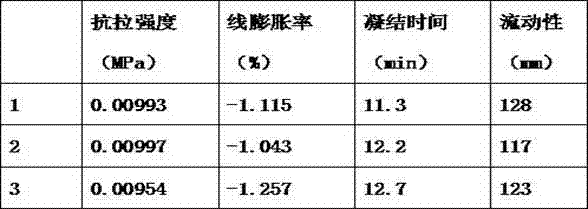

Embodiment 1

[0016] The carbon fiber reinforced tire casting gypsum powder of this embodiment is made of the following raw materials in parts by weight: 10 parts of α gypsum, 15 parts of β gypsum, 17 parts of coal ash powder, 10 parts of chopped carbon fiber, 0.001 part of methanol, ammonium chloride 0.02 parts, polydimethylsiloxane 0.2 parts.

[0017] The average particle diameters of the α-gypsum, β-gypsum, and coal ash powder are 15 μm, 8 μm, and 23 μm, respectively.

[0018] The length of the chopped carbon fibers is 4 mm.

[0019] Preparation: First, weigh the raw materials of each component according to the stated parts by weight, and then place them in a mixer and mix them for 25 minutes.

Embodiment 2

[0021] The carbon fiber reinforced tire casting gypsum powder of this embodiment is made of the following raw materials in parts by weight: 13 parts of α gypsum, 20 parts of β gypsum, 20 parts of coal ash powder, 15 parts of chopped carbon fiber, 0.0015 parts of ethanol, ammonium chloride 0.04 parts, emulsified silicone oil 0.4 parts.

[0022] The average particle diameters of the α-gypsum, β-gypsum, and coal ash powder are 15 μm, 8 μm, and 23 μm, respectively.

[0023] The length of the chopped carbon fibers is 4 mm.

[0024] Its preparation method is with embodiment 1.

Embodiment 3

[0026] The carbon fiber reinforced tire casting gypsum powder of this embodiment is made of the following raw materials in parts by weight: 15 parts of α gypsum, 25 parts of β gypsum, 23 parts of coal ash powder, 20 parts of chopped carbon fiber, 0.002 parts of citric acid, chlorinated Ammonium 0.05 part, natural oil 0.5 part.

[0027] The average particle diameters of the α-gypsum, β-gypsum, and coal ash powder are 15 μm, 8 μm, and 23 μm, respectively.

[0028] The length of the chopped carbon fibers is 4 mm.

[0029] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com