Poly(ether-ether-ketone) composite material, production method and application of sealing member

A technology of polyether ether ketone and composite materials, which is applied to parts in contact between valve components and valve seats, mechanical equipment, engine components, etc., can solve problems such as poor hydrolysis resistance, easy breakage, leakage, etc., and achieve improved mechanical properties , Good hydrolysis resistance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Make 30 seals with a size of 195 / Φ145×17, with a total amount of 10kg.

[0027] 1. Raw material formula:

[0028] PEEK Powder 7.5kg

[0029] Nanoparticles 1kg

[0030] Polyfluoroethylene propylene or polyphenylene sulfide 0.5kg

[0031] Glass fiber 1kg (fiber diameter 6~12um, aspect ratio 3:1~11:1)

[0032] 2. Mixing: Use a high-speed mixer to mix, the mixing speed is 2000 rpm, and the mixing time is 2 minutes.

[0033] 3. Press and form under the above conditions, sinter with gas heat transfer sintering method, the highest sintering temperature is 380±10°C, keep warm for 3 hours, and the heating and cooling speed is 50-80°C / H.

[0034] 4. Secondary annealing treatment to eliminate stress and deformation of the material, the temperature is 200°C±20°C, and the time is 2 hours.

[0035] 5. Machining is carried out after measuring the size.

Embodiment 2

[0036] Embodiment 2: The product can be made completely by adding carbon fiber up to 2kg, and the performance reaches and exceeds the performance of the above-mentioned embodiment.

Embodiment 3

[0037] Embodiment 3: It is better to use metal skeleton material for the sealing member, which can save the composite material of the present invention. cut costs.

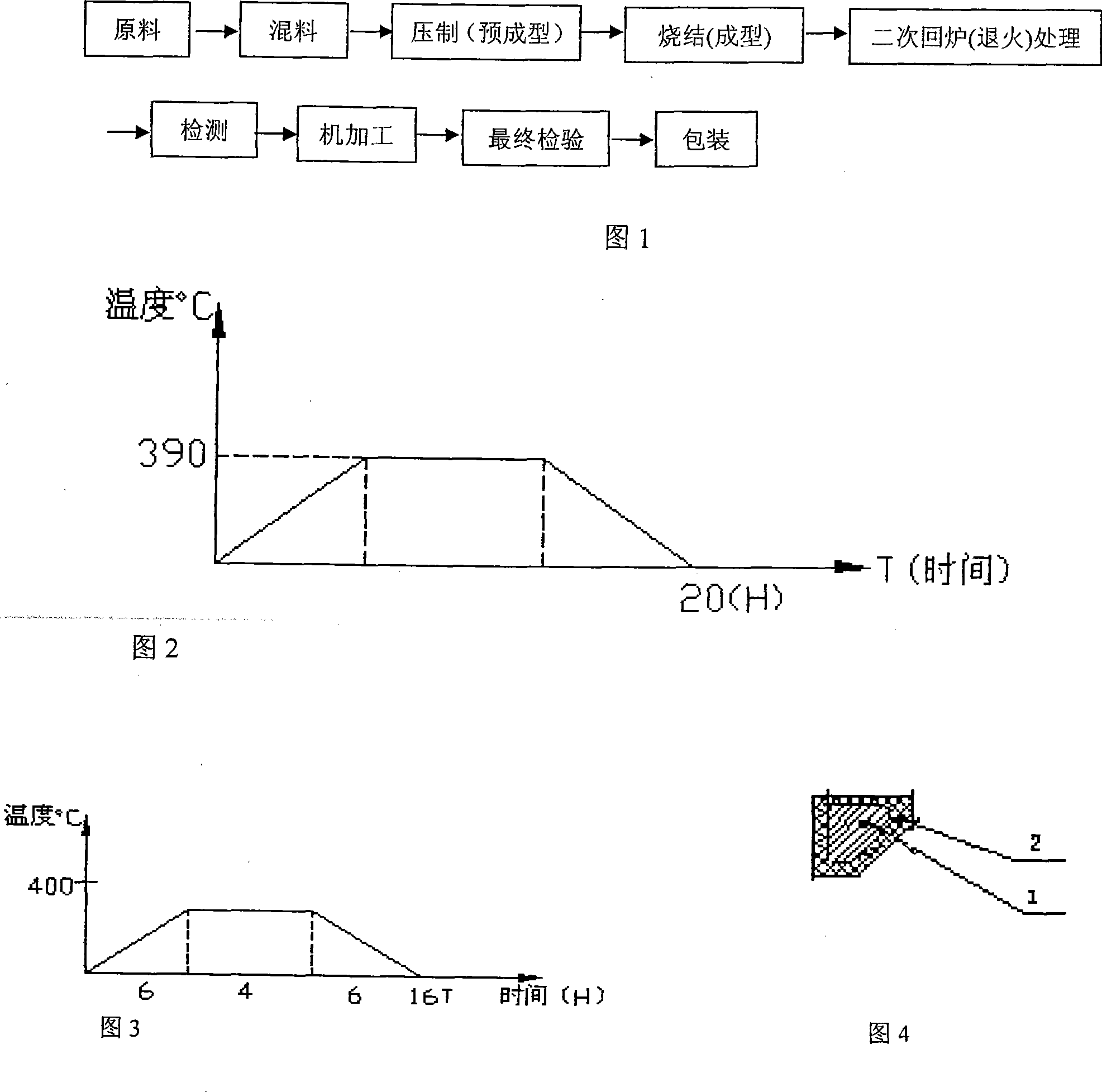

[0038] Method embodiment, (1) compression molding:

[0039] 1. Ingredients: 65-90 parts of polyetheretherketone, 10-30 parts of glass fiber, 2-10 parts of polytetrafluoroethylene, 5-10 parts of molybdenum disulfide, and 10-30 parts of carbon fiber. The above ratios are weight ratios.

[0040] 2. Mix the materials. According to the design requirements, pour the prepared materials into the automatic mixer for mixing and mixing. The mixing time is 0.5 to 1 minute, and the speed of the mixer is 2000 rpm.

[0041] 3. Pressing, put the mixed raw powder into the mold cavity, pressurize at a speed of 20MPa / min at a room temperature of 20±5°C, and the gauge pressure reaches 50MPa / cm 2 , start to deflate gradually, and then keep the pressure for 6 minutes, and the preform is formed.

[0042] 4. Put the pressed preform i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com