Stone composite plate free of glue failure

A composite board and stone technology, applied in the direction of covering/lining, layered products, construction, etc., can solve problems such as hollowing, difficult to control the bonding effect, and affecting the strength and quality of stone composite boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

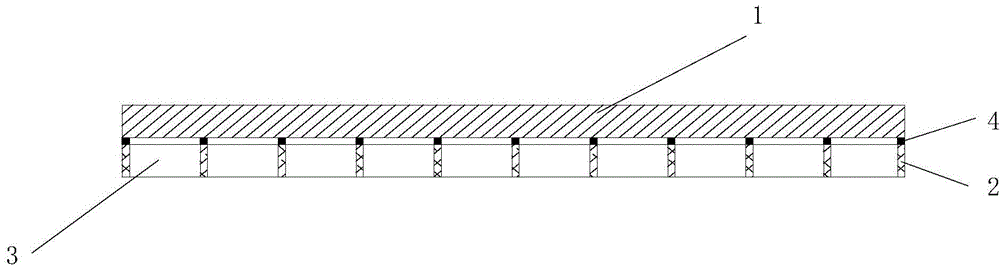

[0023] like figure 1 As shown, a non-adhesive stone composite board includes a stone panel 1 and a base material 2, the base material 2 is hollowed out at intervals to form through holes 3 that penetrate up and down, and the stone panel 1 and the base material 2 are glued with an adhesive 4 catch.

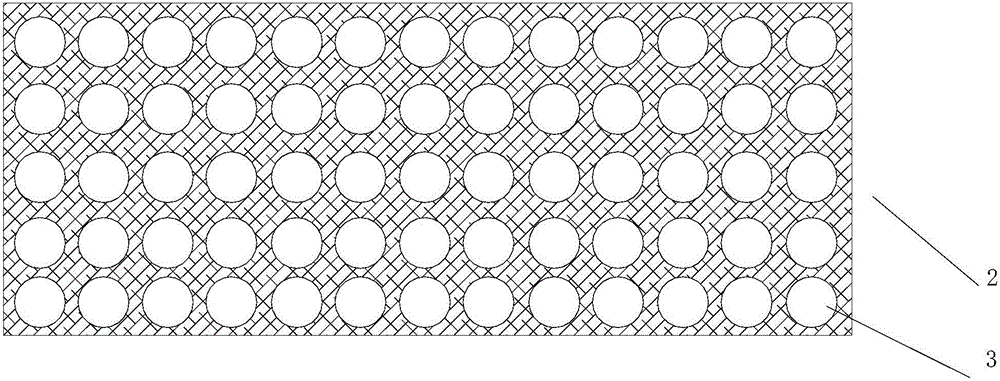

[0024] like figure 2 As shown, the shape of the through hole 3 is circular.

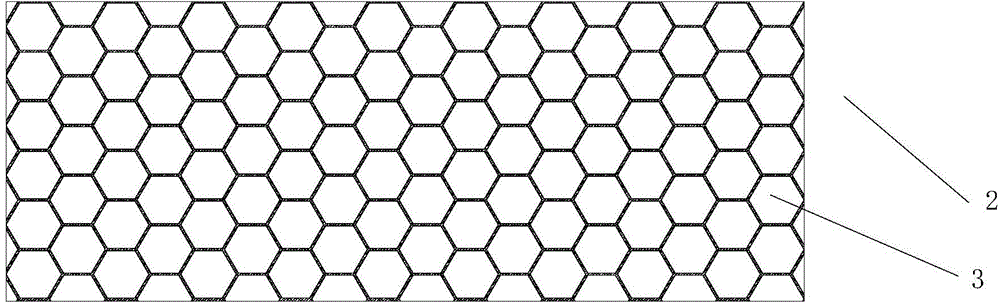

[0025] like image 3 As shown, the shape of the through hole 3 is a regular hexagon, and the base material 2 is a honeycomb shape.

[0026] like Figure 4 As shown, the shape of the through hole 3 is a triangle.

[0027] The above geometric shapes are only examples, and the shape of the through hole can be any geometric shape.

[0028] The thickness of the stone panel 1 is greater than 1 mm.

[0029] The thickness of the base material 2 is greater than 5 mm.

[0030] The range of the substrate 2 is stone, ceramic tile, aluminum plate, including aluminum alloy, plastic aluminum plate, ceramic tile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com