Synthetic diesel

A technology for synthesizing diesel and diesel oil, which is applied in the petroleum industry, liquid carbon-containing fuel, and fuel, and can solve problems such as low enzyme catalytic efficiency, environmental pollution, and long process routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

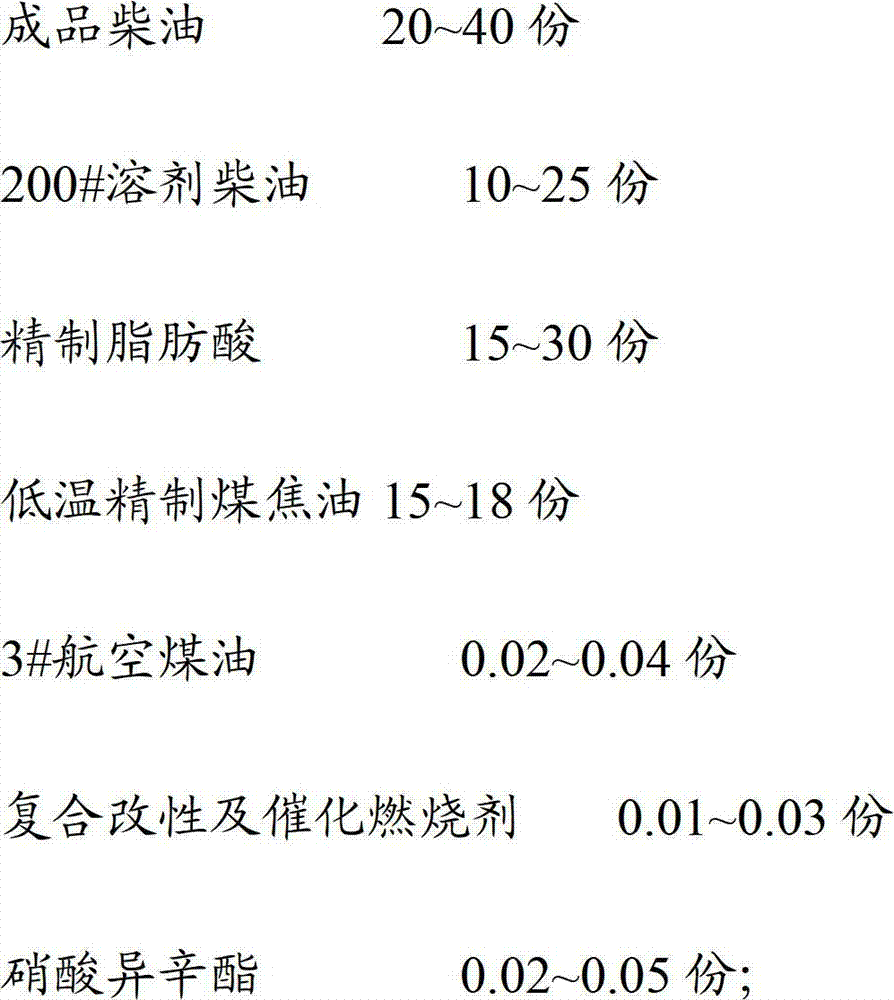

[0033] Take the following weights of ingredients:

[0034] Finished diesel 30kg

[0035] 200# solvent diesel 22 kg

[0036] Refined fatty acids 22 kg

[0037] Low temperature refined coal tar 16 kg

[0038] 3# aviation kerosene 0.03 kg

[0039] Composite modification and catalytic combustion agent 0.02 kg

[0040] 0.03 kg of isooctyl nitrate.

[0041] Synthetic diesel is prepared using the following steps:

[0042] Step 1: Preparation of parent diesel

[0043] The finished diesel oil and CN100412175C composite modified and catalytic combustion agent are mixed and stirred in proportion at normal temperature to obtain the parent diesel oil.

[0044] Step Two: Optimizing Low-Temperature Refined Coal Tar

[0045] The optimized low-temperature refined coal tar can be obtained by blending low-temperature refined coal tar, 3# aviation kerosene and isooctyl nitrate in proportion at room temperature.

[0046] Step Three: Solubilizing Refined Fatty Acids

[0047] Mix 200# solv...

Embodiment 2

[0051] Take the following weights of ingredients:

[0052] Finished diesel 20kg

[0053] 200# solvent diesel oil 25 kg

[0054] Refined fatty acids 15kg

[0055] Low temperature refined coal tar 18 kg

[0056] 3# aviation kerosene 0.02 kg

[0057] Composite modification and catalytic combustion agent 0.03 kg

[0058] Isooctyl nitrate 0.02 kg.

[0059] The synthesis process is the same as in Example 1.

Embodiment 3

[0061] Take the following weights of ingredients:

[0062] 40 kg of finished diesel

[0063] 200# solvent diesel 10 kg

[0064] Refined fatty acid 30 kg

[0065] Low temperature refined coal tar 15 kg

[0066] 3# aviation kerosene 0.04 kg

[0067] Composite modification and catalytic combustion agent 0.01 kg

[0068] Isooctyl nitrate 0.05 kg.

[0069] The synthesis process is the same as in Example 1.

[0070] The synthetic diesel oil that above embodiment 1~3 obtains owing to itself contains abundant oxygen (refining fatty acid contains oxygen), has used catalytic combustion agent in addition, all combustion is sufficient, and tail gas emission is clean, owing to having added isooctyl nitrate (being called again cetane number improver), so that the synthetic diesel fuel is powerful and powerful when used in motor vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com