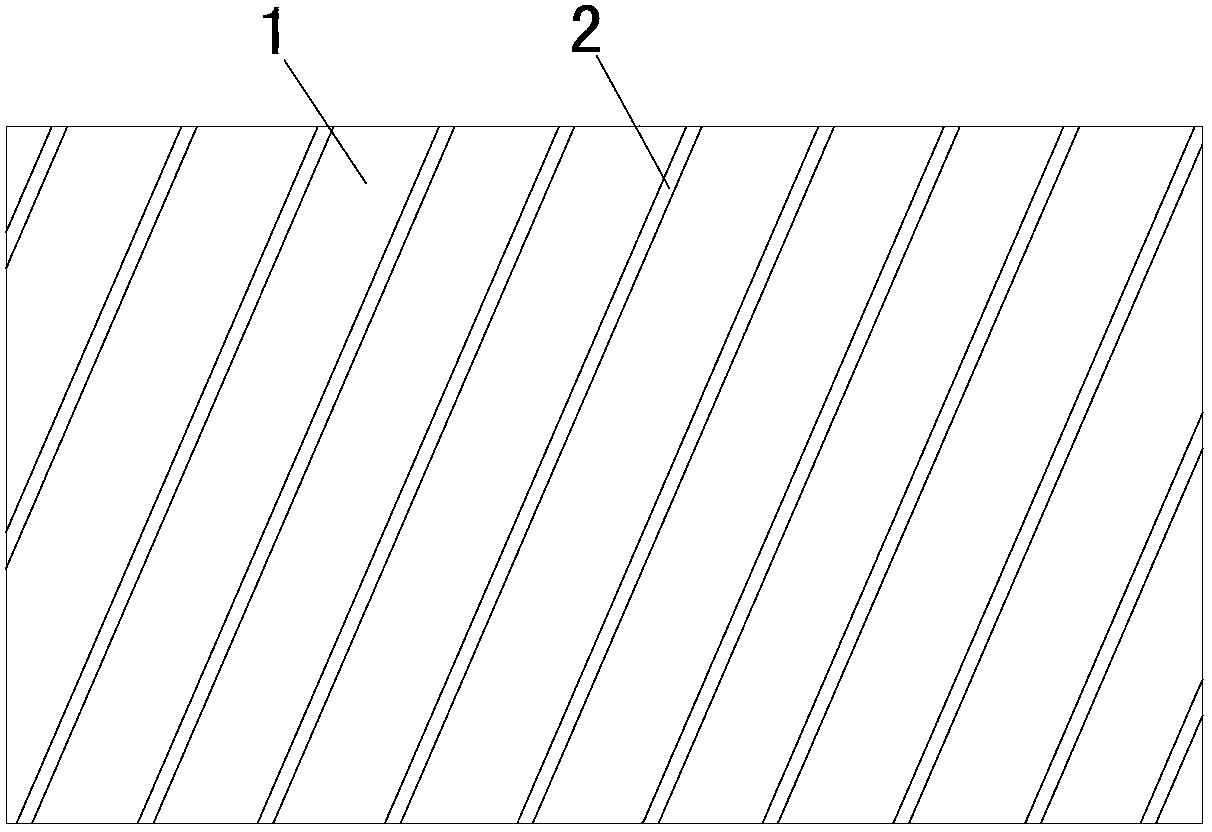

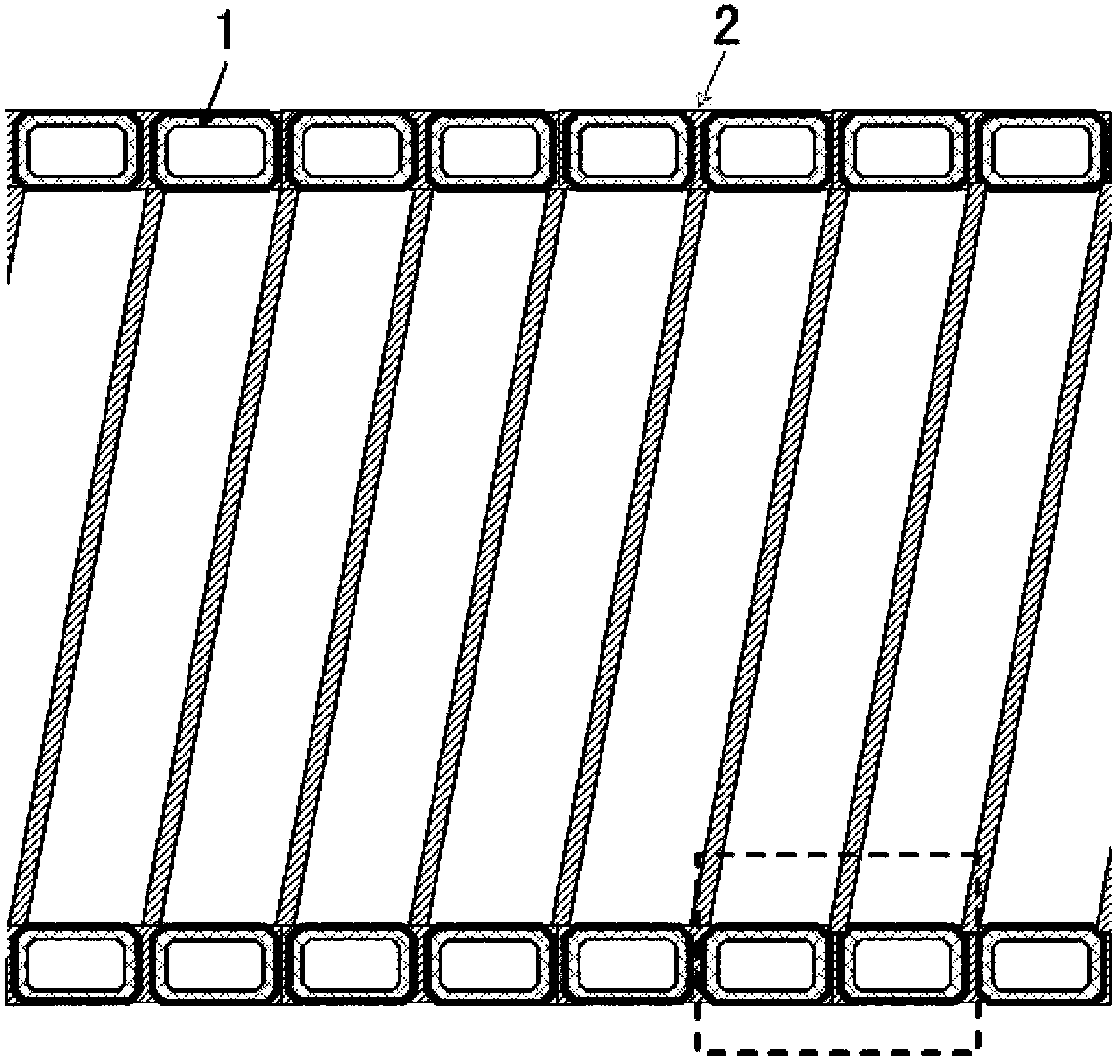

Glass fiber enhanced high-density polyethylene (HDPE) double-walled winding pipe and manufacture method thereof

A production method and a technology of winding pipes, which are applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as difficulty in forming interaction force, degradation of material properties, and fast crystallization speed, and achieve good interface compatibility , Improve the overall performance, the effect of high environmental stress cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] a. Prepare the high-density polyethylene compound according to the following weights:

[0032]

[0033] b. Prepare modified glass fibers by the weight of the following substances:

[0034] Long glass fiber 100 kg,

[0035] Vinyltriethoxysilane 3 kg;

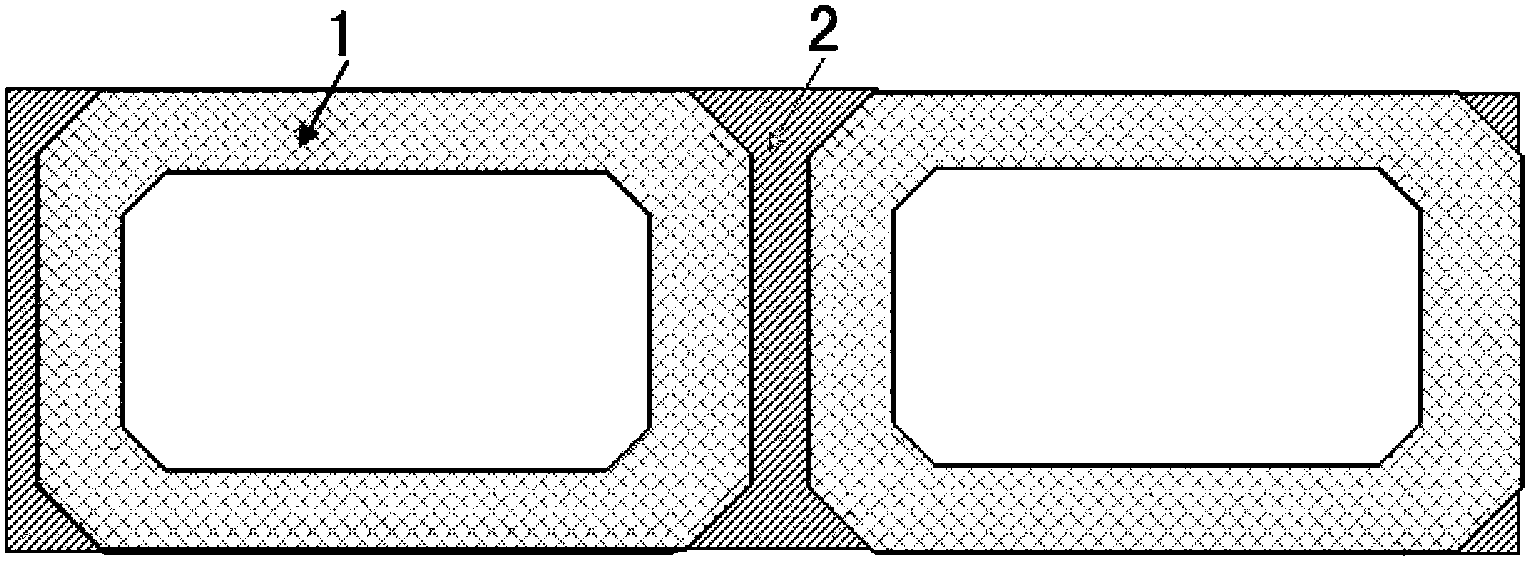

[0036] c. Take 80 kg of the above-mentioned high-density polyethylene compound and 20 kg of modified glass fiber to carry out reaction co-extrusion on a twin-screw extruder, extrude through a die and vacuum shape to obtain a glass fiber-reinforced high-density polyethylene hollow square tube ;

[0037] d. The glass fiber reinforced HDPE hollow square tube is fabricated into a glass fiber reinforced HDPE double-walled winding tube through spiral winding welding.

[0038] The length-to-diameter ratio of the twin-screw extruder is not less than 38:1, the screw temperature is 90-260°C, the rotation speed is 120-600 rpm, and the residence time of the material in the screw extruder is 3-9 minutes.

[0039] The melt index ...

Embodiment 2

[0041] a. Prepare the high-density polyethylene compound according to the following weights:

[0042]

[0043] b. Prepare modified glass fibers by the weight of the following substances:

[0044] Long glass fiber 100 kg,

[0045] Vinyl tris (2-methoxyethoxy) silane 2 kg;

[0046] c. Take 70 kg of the above-mentioned high-density polyethylene compound and 30 kg of modified glass fiber to carry out reaction co-extrusion on a twin-screw extruder, extrude through a mold and vacuum shape to obtain a glass fiber reinforced high-density polyethylene hollow square tube ;

[0047] All the other are with embodiment 1.

Embodiment 3

[0049] a. Prepare the high-density polyethylene compound according to the following weights:

[0050]

[0051] b. Prepare modified glass fibers by the weight of the following substances:

[0052] Long glass fiber 100 kg,

[0053] Vinyl tributylketoxime silane 1 kg;

[0054] c. Take 90 kg of the above-mentioned high-density polyethylene compound and 10 kg of modified glass fiber to carry out reaction co-extrusion on a twin-screw extruder, extrude through a mold and vacuum shape to obtain a glass fiber-reinforced high-density polyethylene hollow square tube ;

[0055] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com