Flexible composite high-pressure delivery pipe

A high-pressure delivery pipe, flexible technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of easy corrosion, high maintenance costs, and many pipeline joints, and achieve strong wear resistance and corrosion resistance, flow Small number of friction lines, easy to store and transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

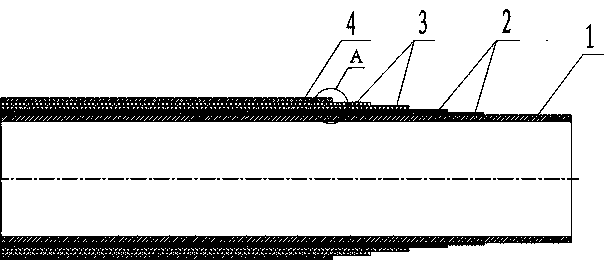

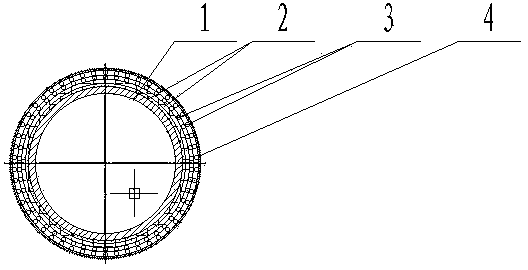

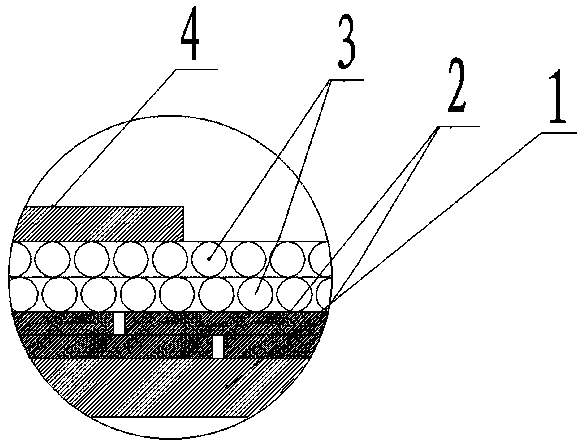

[0026] The present invention as figure 1 , figure 2 , image 3 As shown, the structure includes a medium transmission layer, an enhancement layer, and a protection layer. The enhancement layer is provided with two layers, placed between the medium transmission layer and the protection layer, between the medium transmission layer and the enhancement layer, the enhancement layer and the protection layer Bonded together by heat and pressure.

[0027] One layer of the reinforcement layer is a fiber reinforcement layer, and the other layer is a metal reinforcement layer.

[0028] The fiber-reinforced layer and the metal-reinforced layer are belt-shaped structures formed by applying hot-melt adhesive through a rubber mold.

[0029] The fiber-reinforced layer and the metal-reinforced layer are about 54 from the axis of the pipe 0 Angle, fiber braided belt and steel wire rope reinforced belt bidirectional cross-wound structure, composed of left-helical winding layer and right-h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com