Plastic alloy for washing machine cover plate and preparation method of plastic alloy

A technology of washing machine cover plate and plastic alloy, applied in the field of plastics, can solve the problems of difficult injection molding, low elongation rate, expensive equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

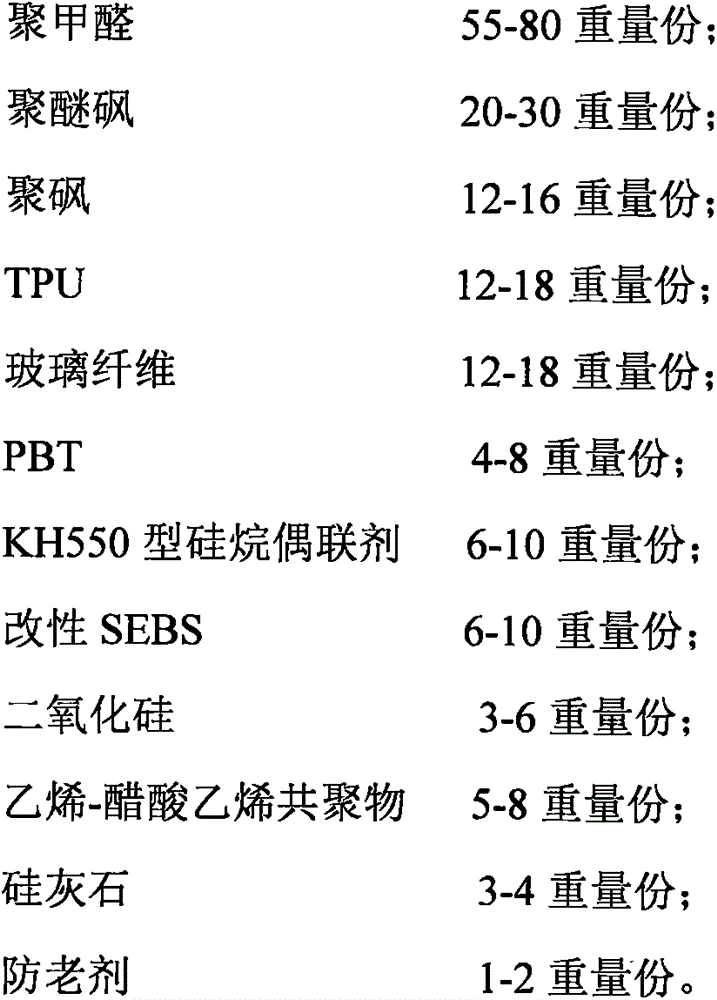

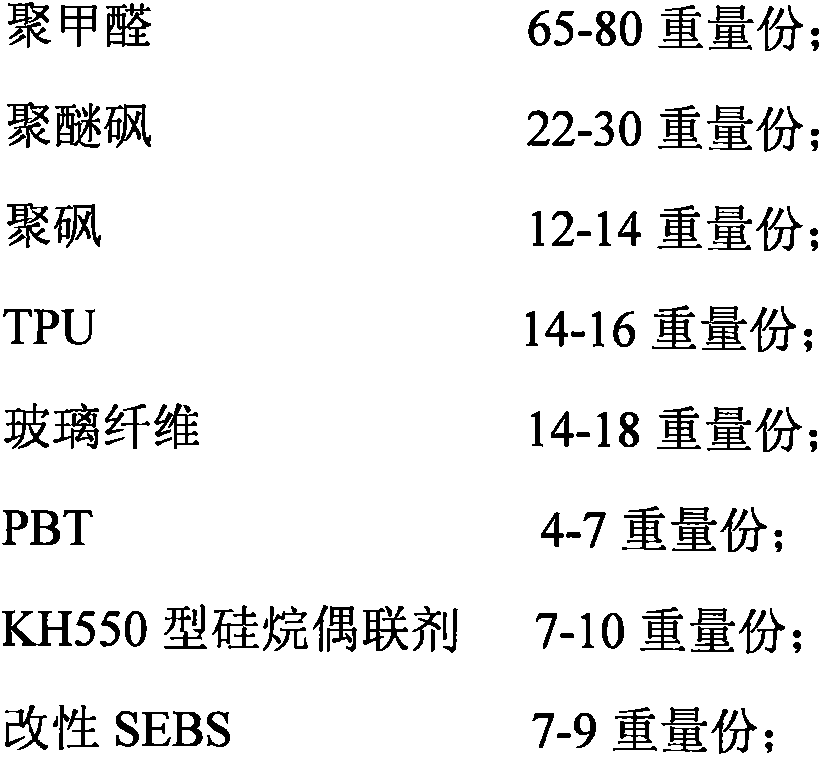

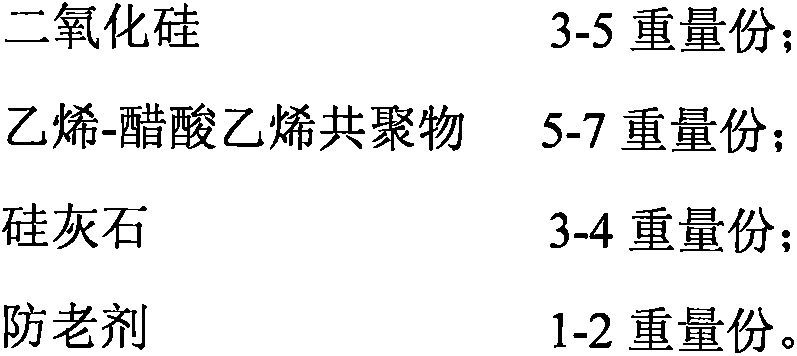

[0068] Correspondingly, the present invention also provides a method for preparing a plastic alloy for a washing machine cover, comprising the following steps: dissolving 6-10 parts by weight of a KH550 type silane coupling agent in a solvent, and then adding 12-18 parts by weight of glass fiber, 3-6 parts by weight of silicon dioxide and 3-4 parts by weight of wollastonite, stirring, adding ammonia water after heating up, continuing to stir, removing excess solvent, and drying to obtain the first mixture; 55-80 parts by weight of polyoxymethylene, 20- 30 parts by weight of polyethersulfone, 12-16 parts by weight of polysulfone, 12-18 parts by weight of TPU, 6-10 parts by weight of modified SEBS, 4-8 parts by weight of PBT and 5-8 parts by weight of ethylene-vinyl acetate copolymer , after stirring, the second mixture is obtained; the second mixture is heated, and then the first mixture and 1-2 parts by weight of anti-aging agent are added, and the third mixture is obtained aft...

Embodiment 1

[0088] The raw material formula of modified SEBS and preparation method thereof are as follows:

[0089] formula:

[0090] SEBS45 parts by weight;

[0091] 12 parts by weight of polyvinyl chloride rubber;

[0092] 8 parts by weight of plasticizer;

[0093] 2 parts by weight of compatibilizer;

[0094] 4 parts by weight of titanium dioxide;

[0095] 3 parts by weight of titanate coupling agent;

[0096] The preparation process is as follows:

[0097] 1. Weigh raw materials by weight;

[0098] 2. Put all the raw materials into a high-speed mixer and mix for 15 minutes, then discharge;

[0099] 3. Put the mixed raw materials into a screw machine to extrude and granulate to obtain modified SEBS. The rotation speed of the screw machine is 400rpm, and the temperature is set at 200°C.

[0100] The raw material formula and preparation process of composite engineering plastic alloy are as follows:

[0101] formula:

[0102] 65 parts by weight of polyoxymethylene;

[0103] 25...

Embodiment 2

[0122] The raw material formula of modified SEBS and preparation method thereof are as follows:

[0123] formula:

[0124] SEBS45 parts by weight;

[0125] 12 parts by weight of polyvinyl chloride rubber;

[0126] 12 parts by weight of plasticizer;

[0127] 3 parts by weight of compatibilizer;

[0128] 5 parts by weight of titanium dioxide;

[0129] 3 parts by weight of titanate coupling agent;

[0130] The preparation process is as follows:

[0131] 1. Weigh raw materials by weight;

[0132] 2. Put all the raw materials into a high-speed mixer and mix for 20 minutes, then discharge;

[0133] 3. Put the mixed raw materials into the screw machine to extrude and granulate. The speed of the screw machine is 300rpm, and the temperature is set at 180°C;

[0134] The raw material formula and preparation process of composite engineering plastic alloy are as follows:

[0135] formula:

[0136] POM 66 parts by weight;

[0137] 24 parts by weight of polyethersulfone;

[0138...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com