Preparation method of high-temperature corundum mullite crucible

A technology of mullite and corundum, which is applied in the field of preparation of high-temperature corundum mullite crucibles, can solve the problems of large fluctuations in product quality, short service life, poor creep resistance, etc., and achieve scientific and reasonable preparation methods and facilitate industrial production , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

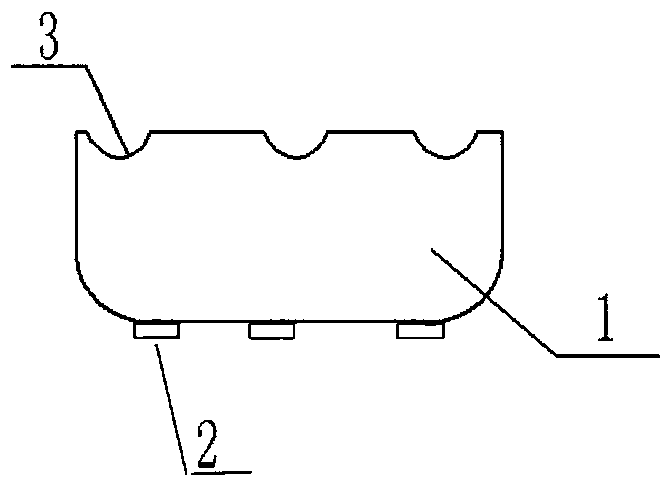

Image

Examples

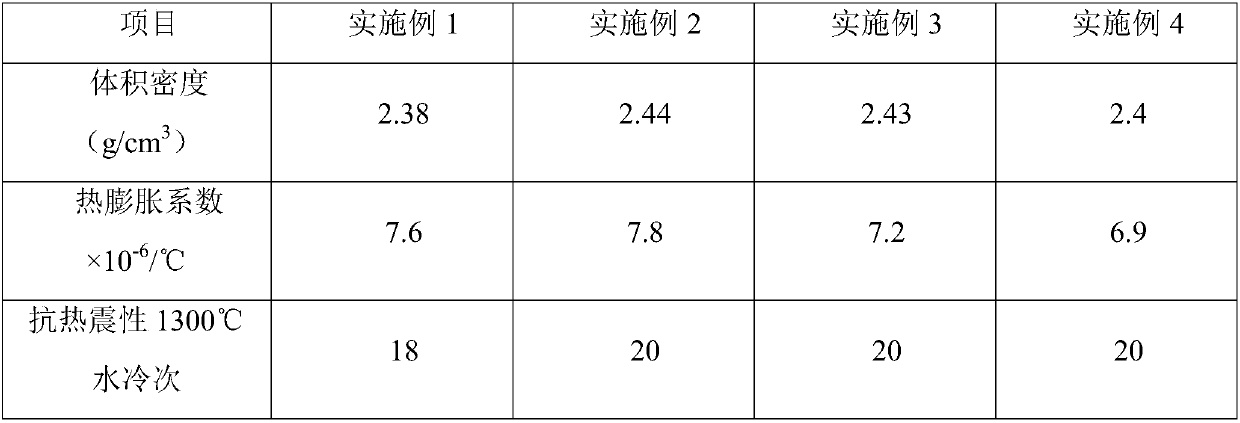

Embodiment 1

[0034] Calcined alumina powder 40%; mullite powder 15%; kyanite powder 10%; kaolin powder 20%; white corundum particles 15%.

[0035] The particle diameters of the calcined alumina powder, mullite powder, kyanite powder and kaolin powder are all 1-44 μm; the particle diameter of the white corundum particles is 50 mesh.

Embodiment 2

[0037] Calcined alumina powder 45%; kyanite powder 10%; kaolin powder 30%; white corundum particles 15%.

[0038] The particle diameters of the calcined alumina powder, kyanite powder and kaolin powder are all 20-60 μm; the particle diameter of the white corundum particles is 18 mesh.

Embodiment 3

[0040] Calcined alumina powder 30%; kyanite powder 10%; kaolin powder 40%; white corundum particles 15%; fused quartz particles 5%.

[0041] The particle diameters of the calcined alumina powder, kyanite powder, kaolin powder and fused silica particles are all 15-50 μm; the particle diameter of the white corundum particles is 100 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com