Sagger for positive electrode material of lithium ion battery

A lithium-ion battery and positive electrode material technology, applied in the field of lithium-ion battery positive electrode materials, can solve the problems of labor-intensive spraying equipment, reduced yield, and increased production costs, so as to reduce production difficulty and equipment investment, reduce The probability of problems and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

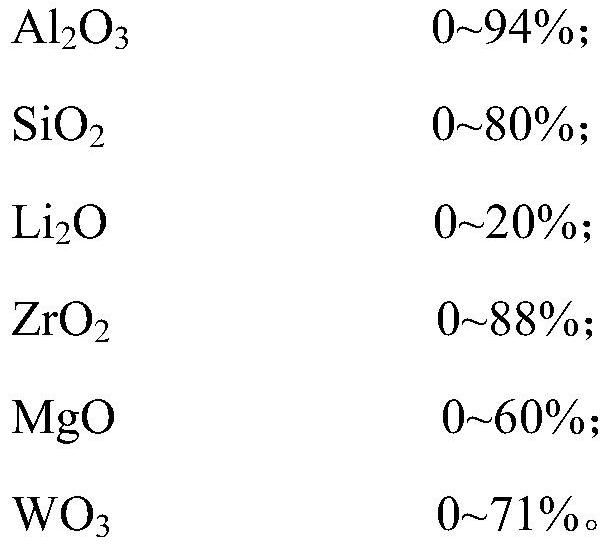

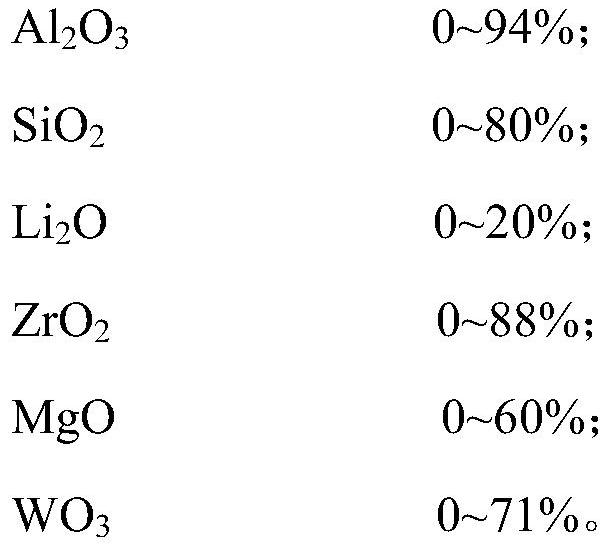

Method used

Image

Examples

Embodiment 1

[0036] Raw materials are prepared according to the weight percentages of the components shown in Table 1. The raw materials are mixed with water to form a workable slurry, wherein the added water accounts for 10% of the weight of all powder raw materials. The slurry is poured into the mold, and the mold is moved to a vibrating table, and vibrated until the slurry is leveled.

[0037] The embryo body injected into the mold (slip injection molding) was naturally cured in the mold for 15 hours, and then demoulded, and the demoulded sagger embryo body was dried at 105° C. for 15 hours.

[0038] Place the dried embryo body in a high-temperature electric furnace (refer to Table 1 for firing temperature), anneal at 1350°C for 3 hours, cool to below 150°C and take it out from the furnace to obtain a sagger for lithium-ion battery positive electrode materials.

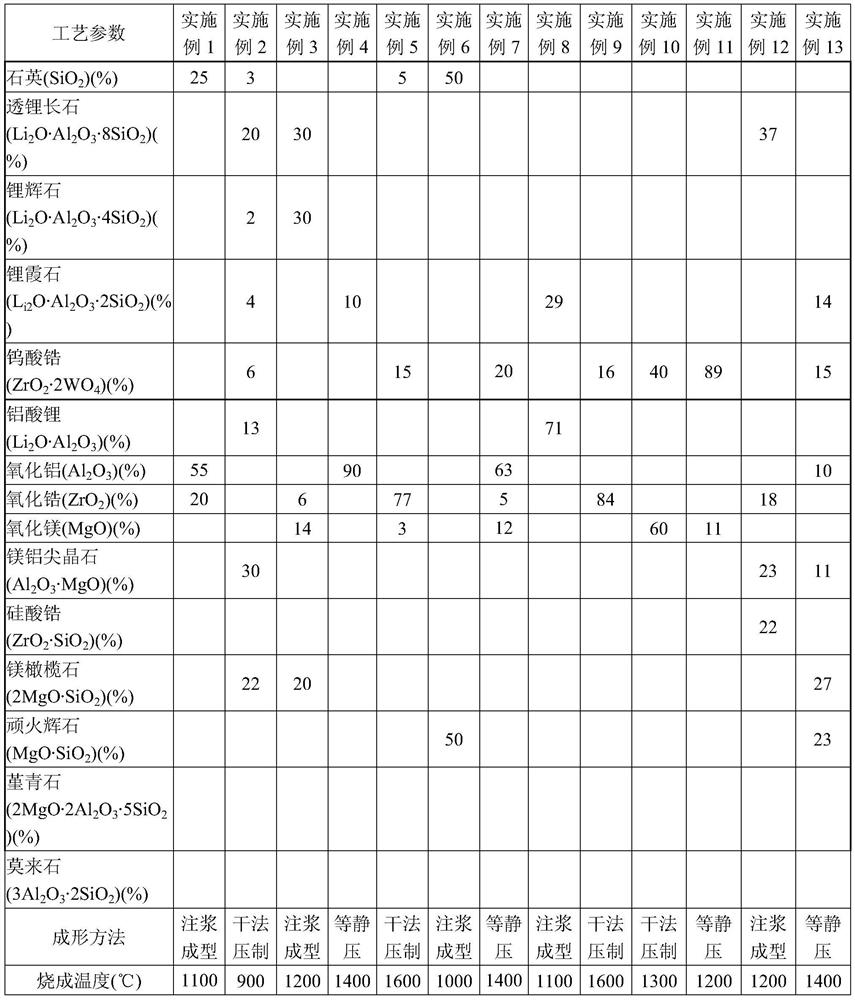

Embodiment 2~13

[0040] Refer to Table 1 for the raw materials and their percentages, molding methods and firing conditions used in each embodiment, and the rest of the steps are the same as those in the above-mentioned embodiment 1, and details will not be repeated here.

[0041] Table 1. Embodiment 1~13 technological parameter

[0042]

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com