Cement kiln coal injection pipe castable

A coal-injection pipe and castable technology, which is applied in the field of high-temperature and alkali-resistant building materials, can solve problems such as short service life, and achieve the effects of improved service life, good stability, and high refractoriness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] For cement kiln coal injection pipe castables, the weight percentage of each raw material component is:

[0025] Raw material name Particle size Weight percent

[0026] Spinel particles 5-8mm 20-25%

[0027] Spinel particles 3-5mm 20-30%

[0028] Spinel particles 1-0mm 20-25%

[0029] Spinel fine powder <0.045mm 8-15%

[0030] Aluminum oxide powder 3-5μm 7-10%

[0031] Alumina micropowder<2μm 1-4%

[0032] Magnesium oxide powder <0.088mm 2-4%

[0033] Pure calcium aluminate cement 6-10%;

[0034] The amount of admixture added is:

[0035] Polyphosphate 0.1%

[0036] Polyethylene glycol 0.08%

[0037] Polycarboxylate ether 0.03%.

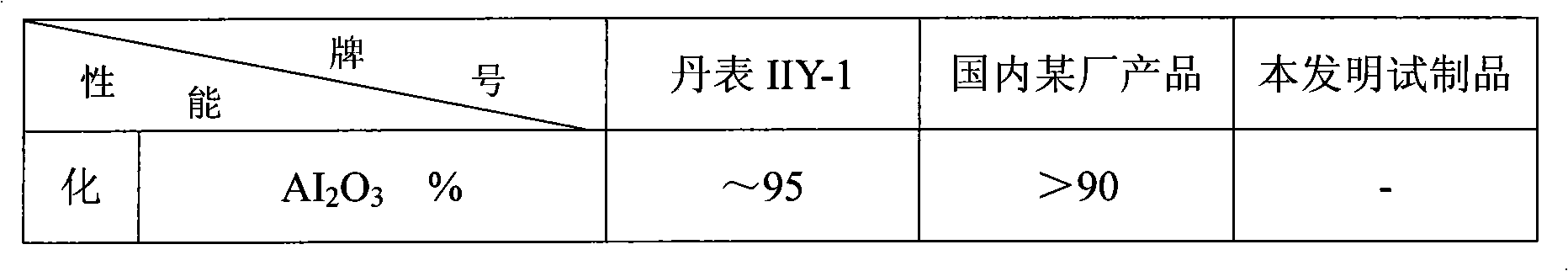

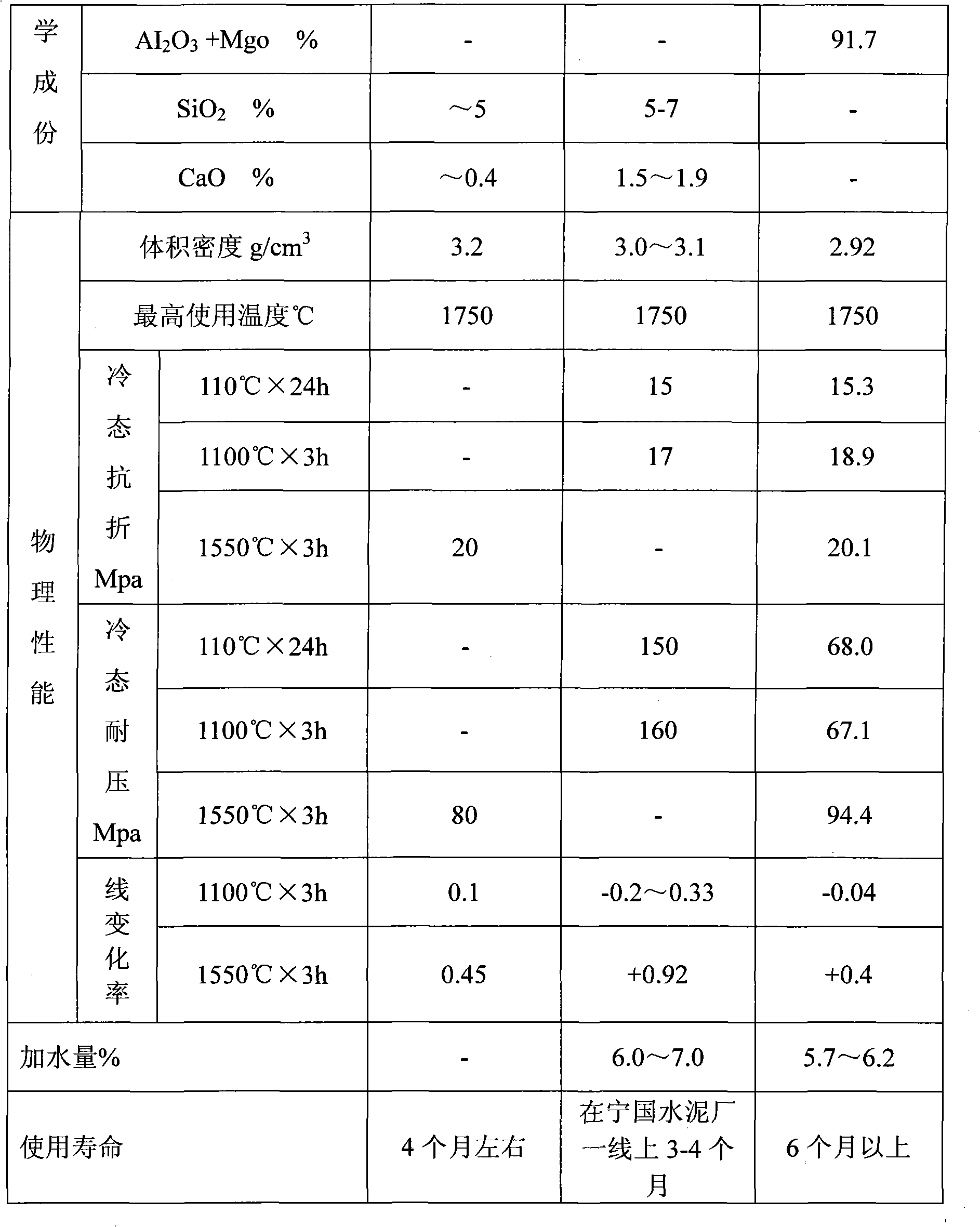

[0038] The performance comparison between the present invention and similar products at home and abroad is shown in Table 1

[0039]

[0040]

[0041] It was tested on the coal injection pipe of the cement kiln with a daily output of 4,000 tons in Ningguo Cement Plant. Before pouring, the mold was pre-painted with butter, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com