Method for making radial direction orientation permanent ferrite rotor

A permanent magnet ferrite and manufacturing method technology, applied in the manufacture of stator/rotor body, inorganic material magnetism, etc., can solve the problems of complex process, material waste, long working hours, etc., reduce raw material loss, improve work efficiency, and improve magnetic properties Can effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

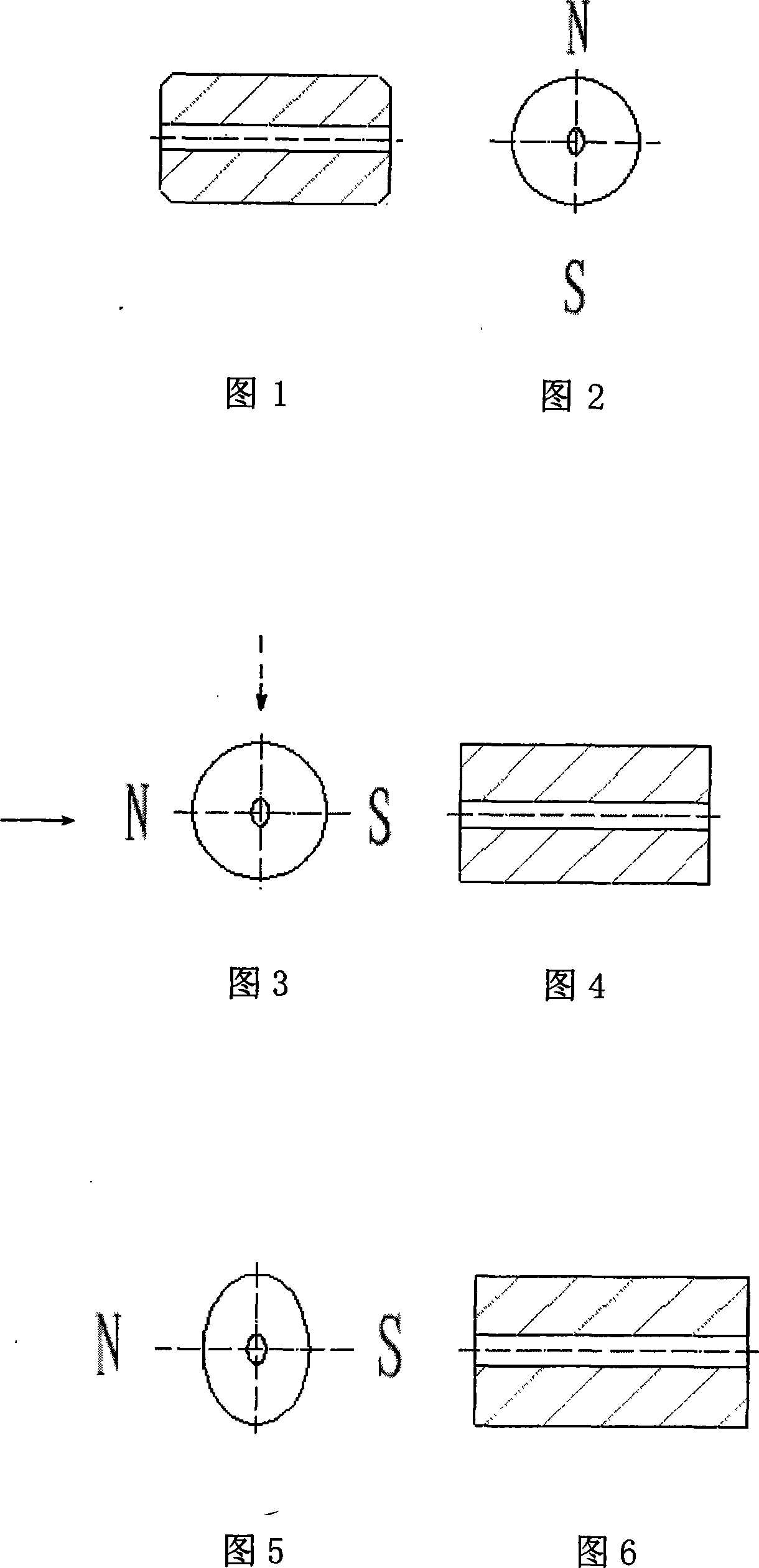

[0041] Take φ19 series products as an example. After firing, the minimum outer diameter process requirement is φ19.7. The structure is shown in Figure 1 and Figure 2, which is barrel-shaped.

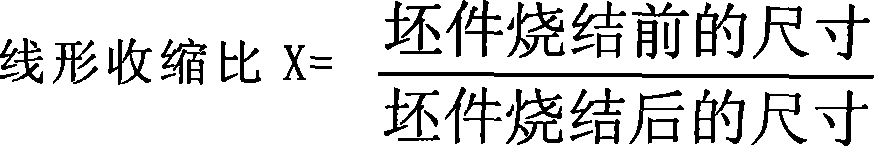

[0042] Traditional method: as shown in Figure 3 and Figure 4, the traditional cylindrical blank is φ26, and the linear shrinkage ratio is X 1 , X 2 The middle values are 1.32 and 1.16 respectively.

[0043] After sintering, the elliptical blank is shown in Figure 5 and Figure 6, and the minor axis of the orientation direction is:

[0044]

[0045] The major axis of the non-orientation direction is:

[0046]

[0047] Error Δ=2a-2b=22.4-19.7=2.71

[0048] The blank produced in this way not only increases the material consumption, but also increases the processing difficulty.

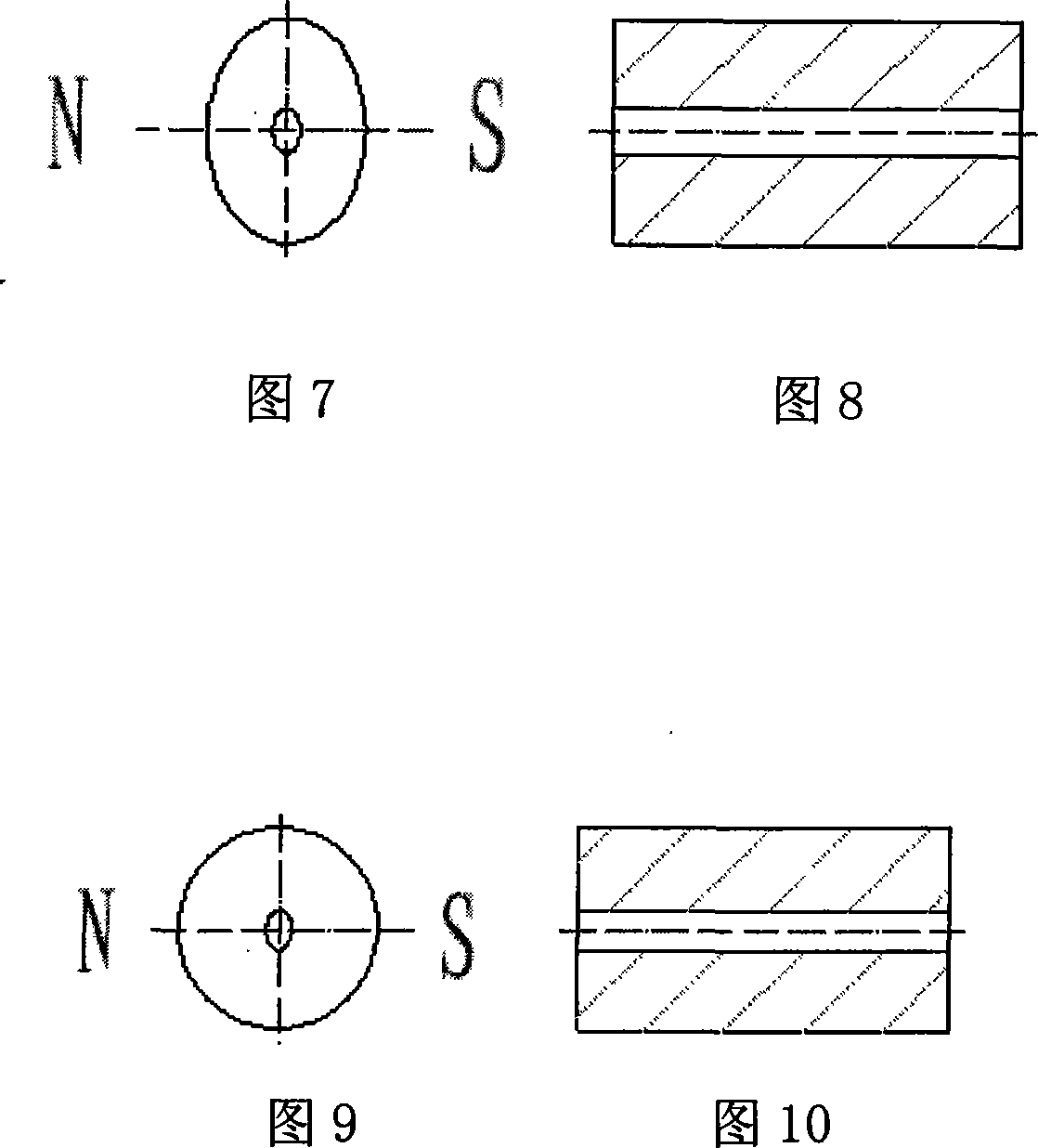

[0049] Forming method of the present invention: as shown in Fig. 7, Fig. 8, its blank is ellipse, after design sintering, it is certain value E=φ19.7 after shrinking in each direction

[0050] Orientat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com