Preparation method of black rock wool

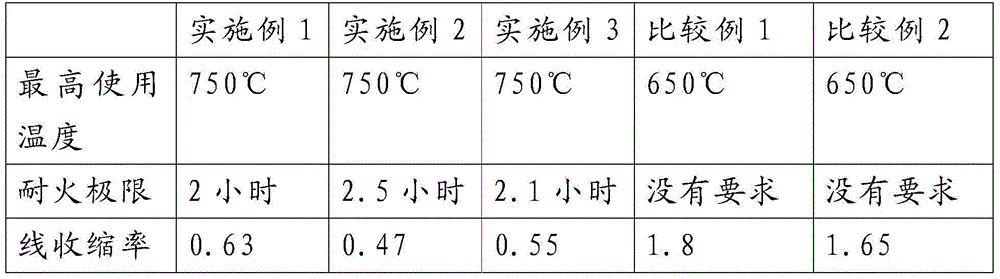

A rock wool and basalt technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of poor high temperature shrinkage resistance and high temperature stability, and can not meet the fire protection and smoke barrier of external wall thermal insulation system, so as to improve the resistance to high temperature. Heat, prevent decomposition, strengthen the effect of the network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention discloses a method for preparing black rock wool, comprising the following steps:

[0026] (A) melting 300-400 parts by weight of basalt, 200-300 parts by weight of iron ore, 130-220 parts by weight of blast furnace slag and 150-250 parts by weight of coke;

[0027] The amount of oxygen introduced in the melting process is 3-5% of the total mass of basalt, iron ore, blast furnace slag and coke;

[0028] (B) Centrifugal blowing of the melt into fibers;

[0029] (C) collecting the fibers, superimposing them, pressurizing and pleating them, and setting them in a curing oven under high temperature and pressure to obtain black rock wool.

[0030] In the present invention, black rock wool is prepared by using basalt, iron ore, and blast furnace slag as raw materials and coke as an energy source. In the present invention, iron ore and blast furnace slag are used to completely replace alkaline raw materials such as dolomite in ordinary ...

Embodiment 1

[0042] Melting 360 parts by weight of basalt, 200 parts by weight of iron ore, 220 parts by weight of blast furnace slag and 200 parts by weight of coke at 1400 ° C;

[0043] The amount of oxygen introduced in the melting process is 3.5% of the total mass of basalt, iron ore, blast furnace slag and coke;

[0044] The molten material is centrifugally blown and thrown into fibers, and at the same time, the phenolic resin with a mass concentration of 5% is sprayed; the spraying amount of the phenolic resin is 300 kg / ton of product.

[0045] The fibers are collected, superimposed, pressurized and pleated, and cured under high temperature and pressure to obtain black rock wool.

Embodiment 2

[0047] Melting 360 parts by weight of basalt, 240 parts by weight of iron ore, 200 parts by weight of blast furnace slag and 200 parts by weight of coke at 1450 ° C;

[0048] The amount of oxygen introduced in the melting process is 4% of the total mass of basalt, iron ore, blast furnace slag and coke;

[0049]The molten material is centrifugally blown into fibers, and at the same time, phenolic resin with a mass concentration of 5.5% is sprayed; the spraying amount of the phenolic resin is 340 kg / ton of product.

[0050] The fibers are collected, superimposed, pressurized and pleated, and cured under high temperature and pressure to obtain black rock wool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com