Method for preparing Li4SiO4 ceramic powder by water-based sol-gel process

A technology of ceramic powder and gel method, which is applied in the field of ceramic materials, can solve problems such as easy hydrolysis, and achieve the effects of energy saving, cost reduction, and high sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

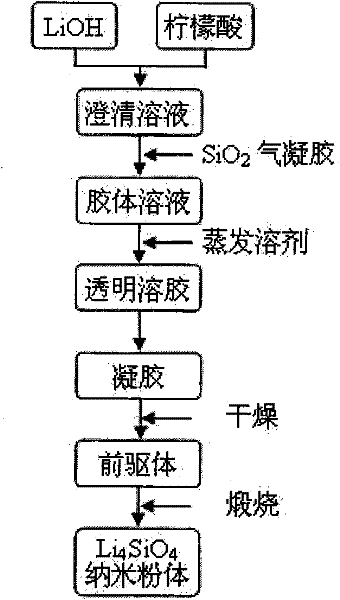

[0049] Such as figure 1 Shown: Preparation of Li by water-based sol-gel method 4 SiO 4 Process flow of ceramic powder:

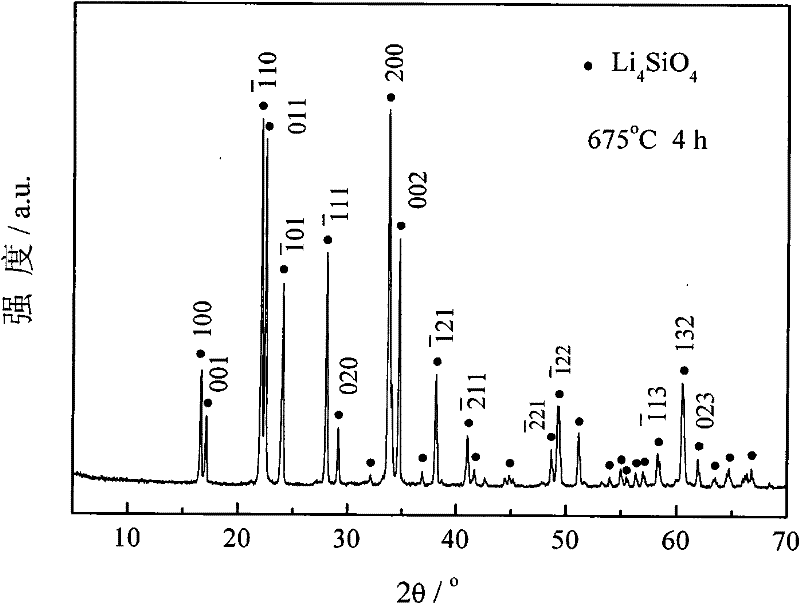

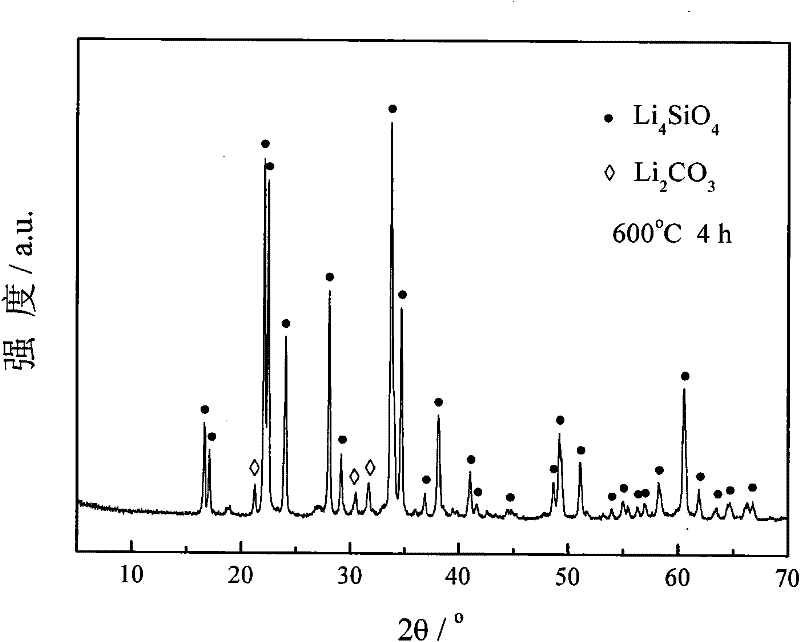

[0050] ① Dissolve LiOH in deionized water, prepare 400 mL of LiOH solution with a molar concentration of 0.4 mol / L, and then add dropwise an aqueous solution of citric acid with a molar concentration of 0.5 mol / L to complex Li + , and use C 6 h 8 o 7 ·H 2 O solution adjusts the pH value of the above solution, PH=6; ② Slowly add SiO dropwise to the solution obtained in step ① according to the molar ratio Li / Si=4 / 1 of Li and Si 2 Airgel and stirred continuously for 0.5h to obtain a slightly milky white colloidal solution; ③evaporate the solvent in the solution obtained in step ② at 70°C until sol-gel transition occurs; ④place the prepared gel at 90°C After aging in an oven for 12 hours, dry at 160°C for 12 hours to obtain a xerogel precursor; ⑤calcin the xerogel precursor at 675°C for 4 hours in an air atmosphere to obtain Li 4 SiO 4 Ceramic powder. ...

Embodiment 2

[0054] Dissolve LiOH in deionized water, prepare 400mL of three LiOH solutions with a molar concentration of 0.4mol / L each, and use C with a concentration of 0.5mol / L 6 h 8 o 7 ·H 2 O regulates the pH value of above-mentioned solution, makes the pH of solution be respectively 5,8.5,10, and other process and process parameter are with embodiment 1.

[0055] After testing, the XRD pattern of the ceramic powder obtained under the conditions of the three pH values is the same as figure 2 It is exactly the same, that is, the powders prepared under the conditions of pH=5, 8.5, and 10 are all single-phase Li 4 SiO 4 Nano powder.

Embodiment 3

[0057] Dissolve LiOH in deionized water, prepare 400 mL of LiOH solution with a molar concentration of 0.4 mol / L, and add C with a concentration of 0.5 mol / L 6 h 8 o 7 ·H 2 O adjusts the pH of the above solution=6; slowly add SiO to the above solution according to the molar ratio Li / Si=3.4 / 1 2 Airgel is stirred continuously, and other process parameters are the same as in Example 1. The xerogel was calcined at 675°C for 4 hours, and the main crystal phase of the obtained ceramic powder was Li 4 SiO 4 , containing only a small amount of Li 2 SiO 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com