Double-end-face grinding machine dressing device

A double-end grinding machine and dressing device technology, which is applied to abrasive surface adjustment devices, parts of grinding machine tools, grinding/polishing equipment, etc. The effect of reducing the overall manufacturing difficulty and ensuring the parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

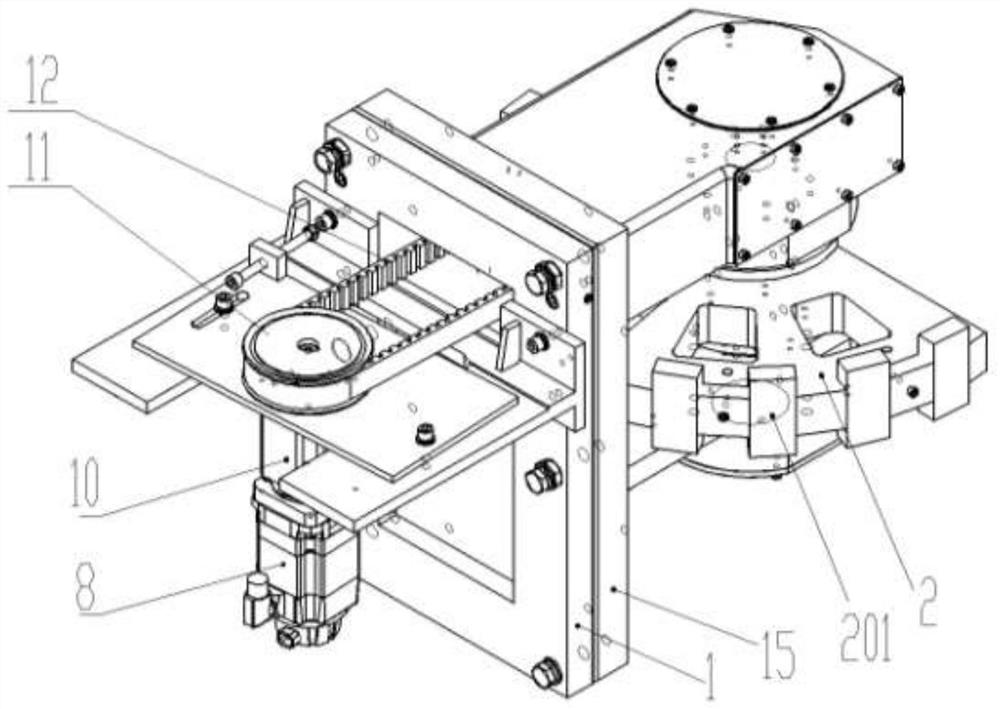

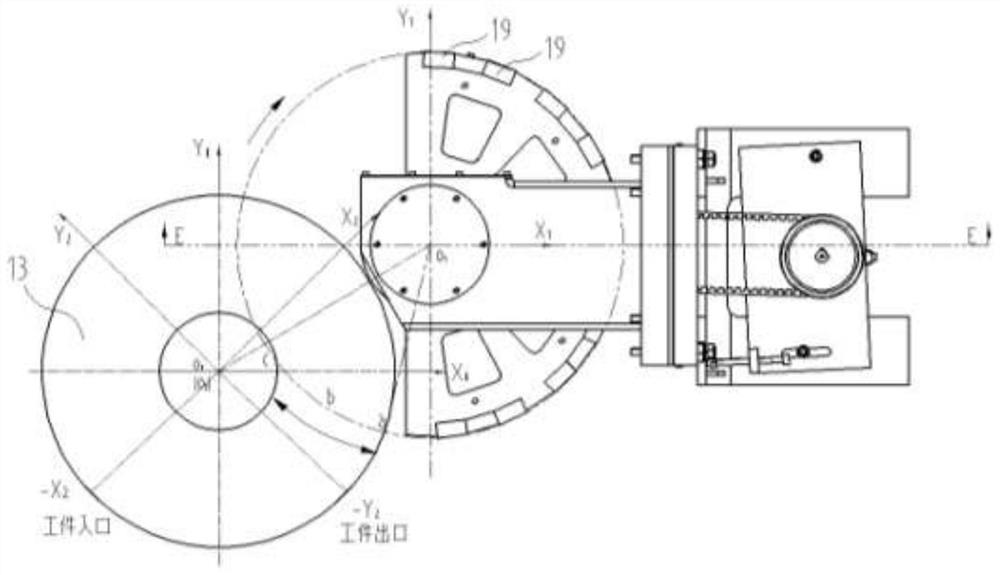

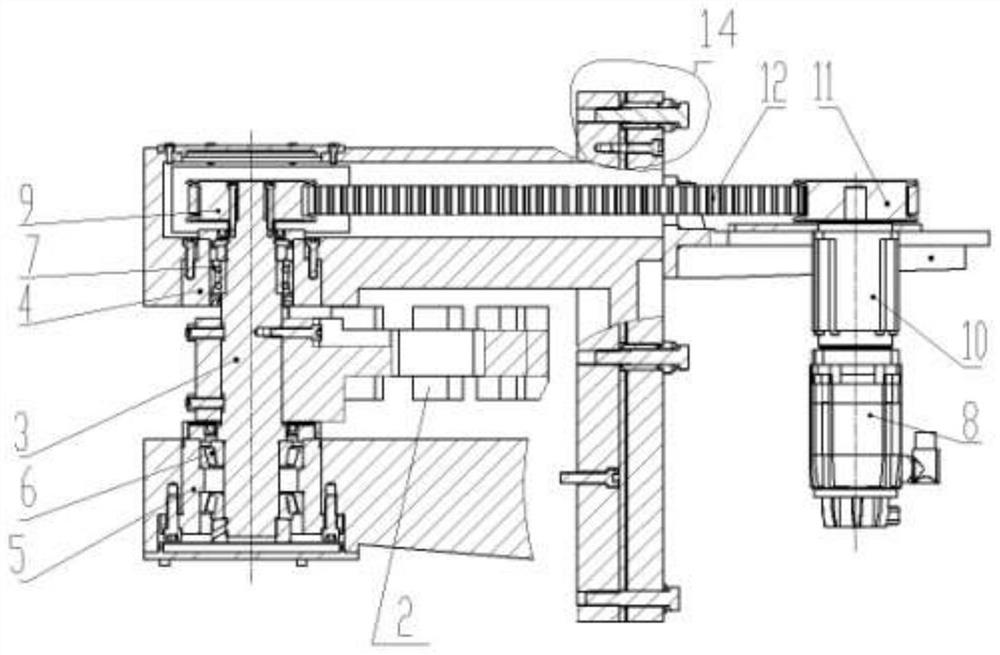

[0027] Such as Figure 1-3 As shown, the present embodiment includes the trimming seat body 1. The trimming seat body 1 has a flange seat and is fixed on the installation backing plate 15. The trimming seat body 1 is provided with a through hole, and the upper bearing seat 4 and the lower bearing seat 4 are arranged in the through hole. Bearing block 5 and trimming shaft 3, upper bearing block 4 is equipped with upper bearing 7, lower bearing block 5 is equipped with lower bearing 6, the upper and lower ends of trimming shaft 3 are respectively sleeved with upper bearing 7 and lower bearing 6, the trimming shaft 3 The upper end is equipped with synchronous belt pulley 9, and the middle part of trimming shaft 3 is connected with trimming disc 2 by screw, and this trimming disc 2 is semicircular, and the circumferential direction of tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com