Preparation method of diamond roller for efficiently trimming CBN grinding wheel

A diamond roller, high-efficiency technology, applied in the direction of metal processing equipment, manufacturing tools, grinding machine parts, etc., can solve the problems of unsatisfactory, frequent replacement, high defective rate, etc., to achieve reduced defective rate, convenient operation, The effect of long product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

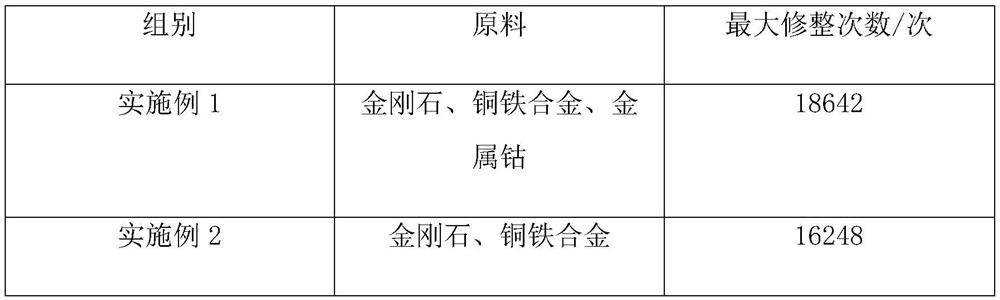

Embodiment 1

[0028] Embodiment 1: a kind of diamond roller preparation method of high-efficiency dressing CBN emery wheel mainly comprises the following steps:

[0029] S1: Raw material preparation

[0030] Get the diamond particle and copper-iron alloy powder that total mass is 56.5g, the mass ratio of diamond particle and copper-iron alloy powder is 13:37, and diamond particle is selected 30 grains / cm 2 The natural diamond or artificial diamond, the mass percent of copper and iron in the copper-iron alloy powder is 3:7, puts diamond particle and copper-iron alloy powder into the micro mixer and stirs for 10min to obtain mixed powder, then adds 2g lubricant in the mixed material, The lubricant is epoxy resin loaded with metal cobalt, continue stirring for 1 hour to obtain the mixed material, put the mixed material in a sealed bag, vacuum the sealed bag to 5Pa and save it for later use.

[0031] The total mass of diamond particles and copper-iron alloy powder is calculated through the joi...

Embodiment 2

[0039] Embodiment 2: a kind of diamond roller preparation method of high-efficiency dressing CBN emery wheel mainly comprises the following steps:

[0040] S1: Raw material preparation

[0041] Get the diamond particle and copper-iron alloy powder that total mass is 57g, the mass ratio of diamond particle and copper-iron alloy powder is 15:37, and diamond particle is selected 55 grains / cm 2 Natural diamond or artificial diamond, the mass percentage of copper and iron in the copper-iron alloy powder is 3:7, the diamond particles and the copper-iron alloy powder are put into a micro-mixer and stirred for 15 minutes to obtain a mixed powder, and then 2.5g of lubricant is added to the mixed material , the lubricant is epoxy resin loaded with metal cobalt, continue to stir for 1.5h to obtain the mixed material, put the mixed material in a sealed bag, vacuum the sealed bag to 6.5Pa and save it for later use.

[0042] The total mass of diamond particles and copper-iron alloy powder is...

Embodiment 3

[0050] Embodiment 3: a kind of diamond roller preparation method of high-efficiency dressing CBN emery wheel mainly comprises the following steps:

[0051] S1: Raw material preparation

[0052] Get the diamond particle and copper-iron alloy powder that total mass is 57.5g, the mass ratio of diamond particle and copper-iron alloy powder is 17:37, and diamond particle is selected 80 grains / cm 2 Natural diamond or artificial diamond, the mass percentage of copper and iron in the copper-iron alloy powder is 3:7, put diamond particles and copper-iron alloy powder into a micro mixer and stir for 20min to obtain a mixed powder, then add 3g of lubricant to the mixed material, The lubricant is epoxy resin loaded with metal cobalt, continue to stir for 2 hours to obtain the mixed material, put the mixed material in a sealed bag, vacuum the sealed bag to 8Pa and save it for later use.

[0053] The total mass of diamond particles and copper-iron alloy powder is calculated through the joi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com