Numerical-control relief grinding machine

A shovel grinding machine, lathe bed technology, applied in the field of numerical control processing equipment, can solve the problems of inability to guarantee the training of operators, complex and frequent operations, and shortage of skilled operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

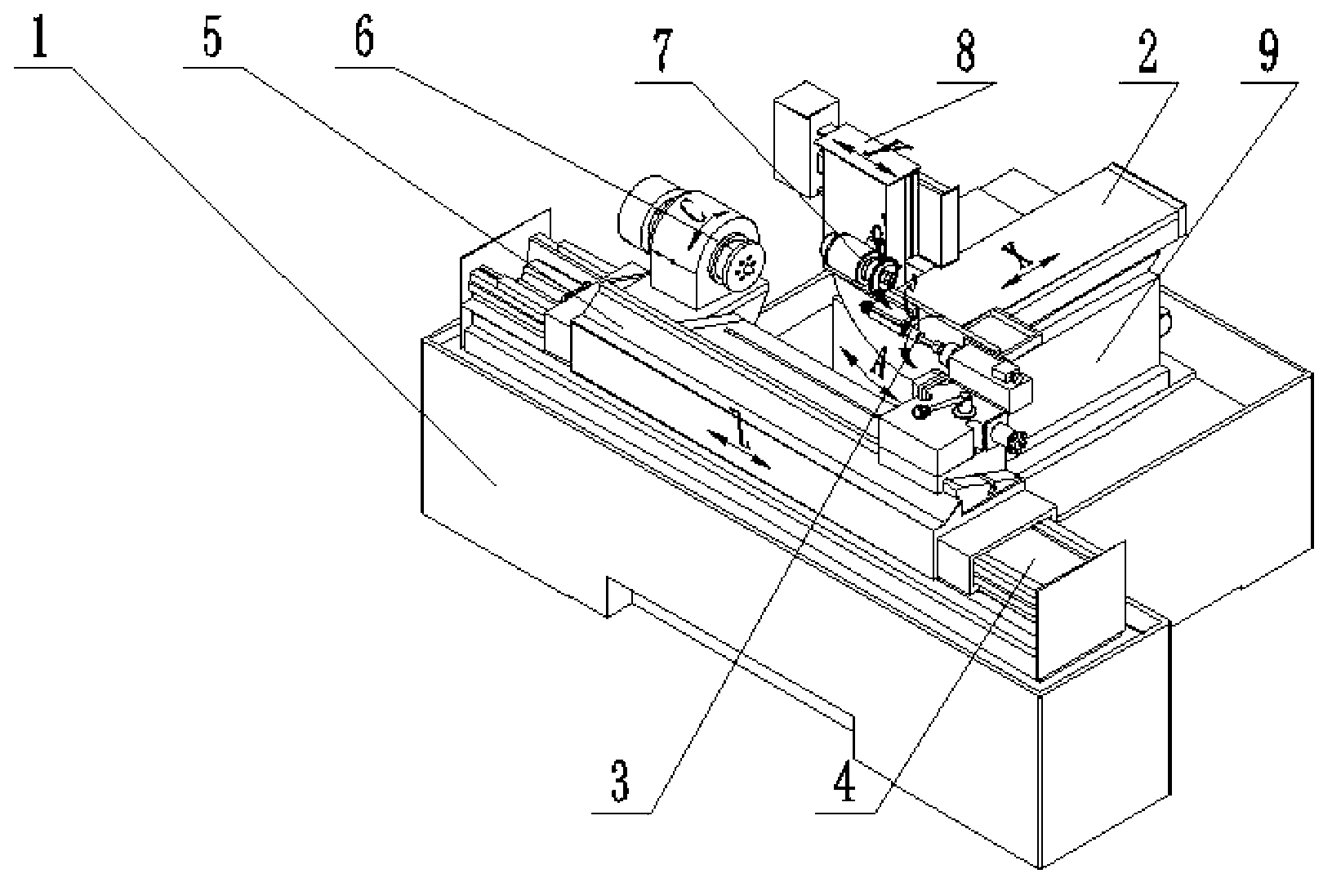

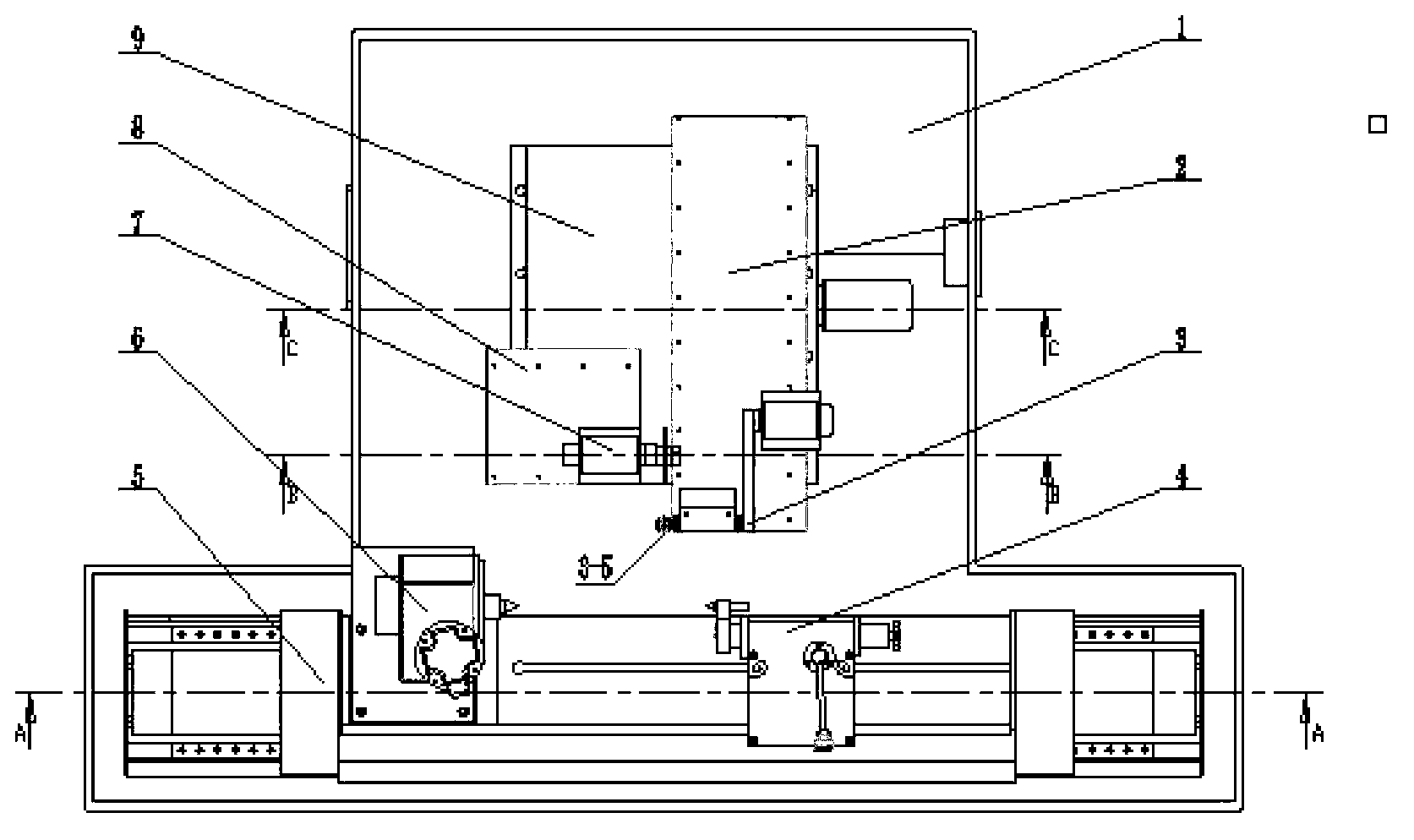

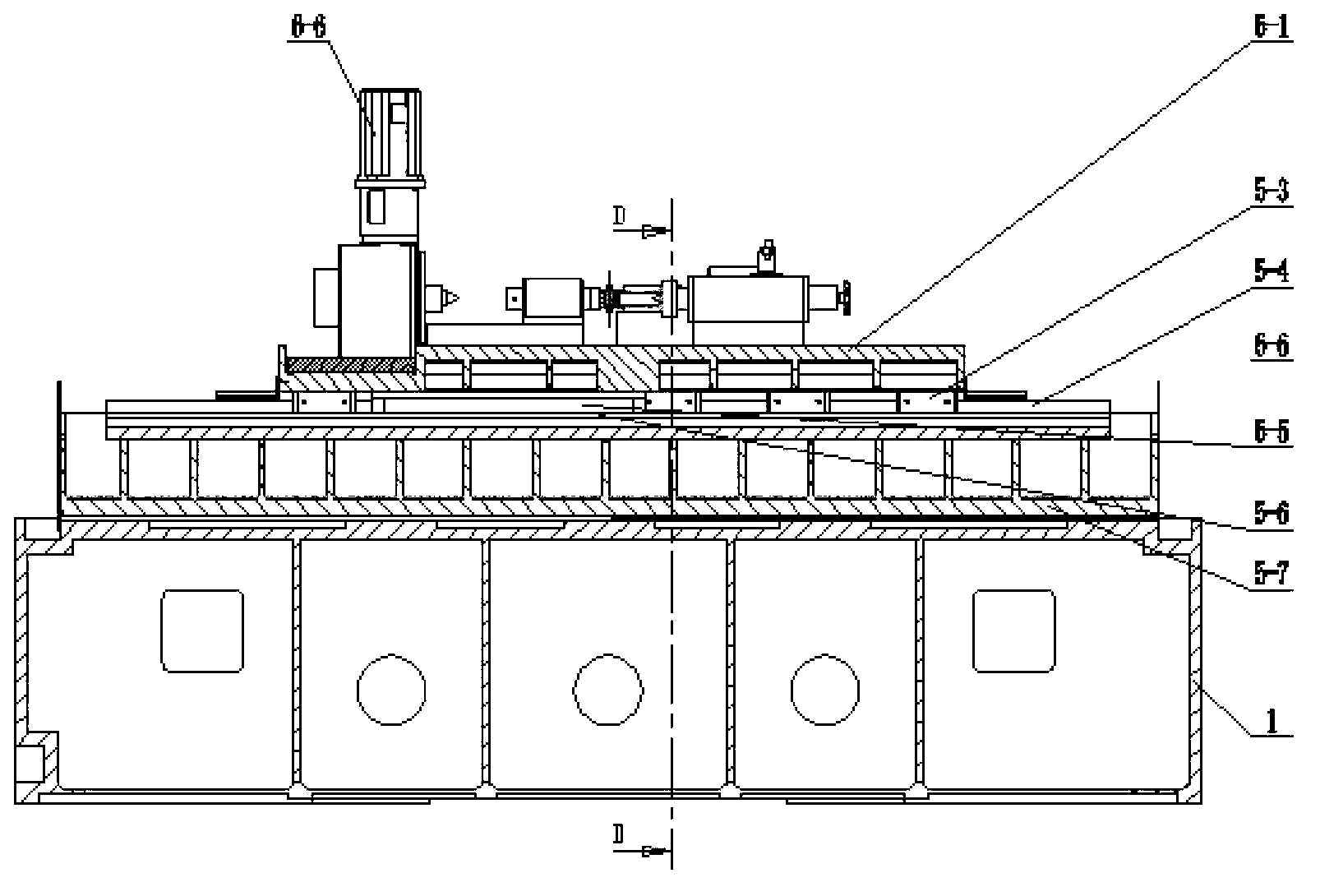

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0023] This example Figure 1 to Figure 8 As shown, a numerically controlled shovel grinder, which includes a cast-shaped zigzag-shaped lathe bed 1, said lathe bed 1 is provided with a Z-direction motion device 5 and a rotary table that move along the Z-direction of the lathe bed 1 Part 9, the Z-direction motion device 5 includes a Z-direction base 5-7, the Z-direction base 5-7 is arranged on the lathe bed 1, and the Z-direction base 5-7 is equipped with a motor 5-5 and a linear motor composed of a motor magnetic plate 5-6, the linear motor provides driving force to drive the Z-direction sliding table 5-1 to move along the linear guide rail 5-4 provided with the guide rail slider 5-3, the The Z-direction sliding table 5-1 is provided with an indexing part 6, a tailstock 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com