Burr trimming device for blockboard

A blockboard and trimming device technology, which is applied in the direction of grinding drive devices, machine tools suitable for grinding the edge of workpieces, manufacturing tools, etc., can solve the problem of manual polishing that is time-consuming, labor-intensive, and harmful Health and other problems, to speed up the trimming efficiency, shorten the trimming time, and reduce the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

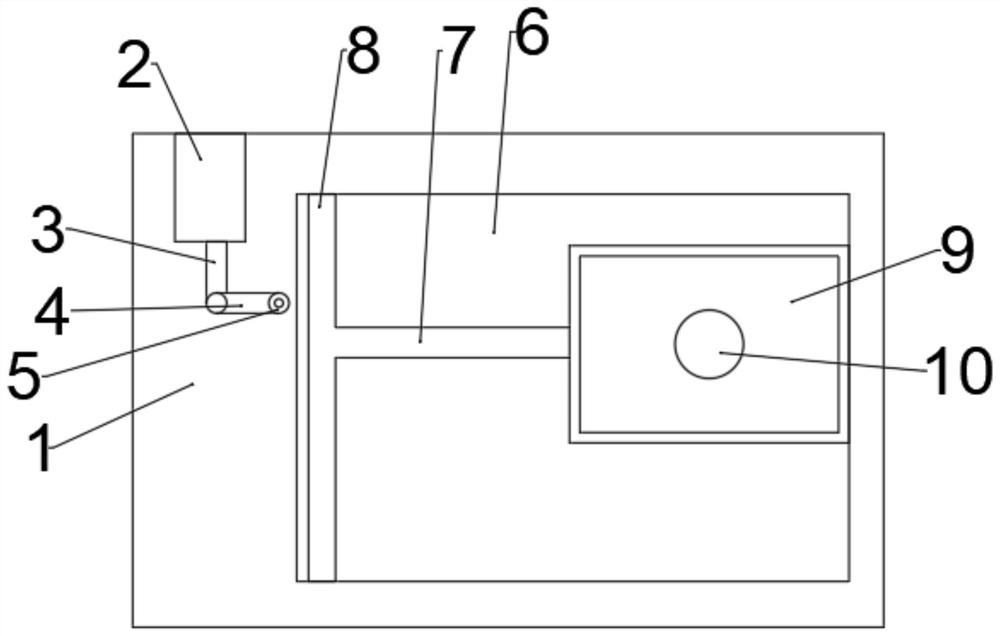

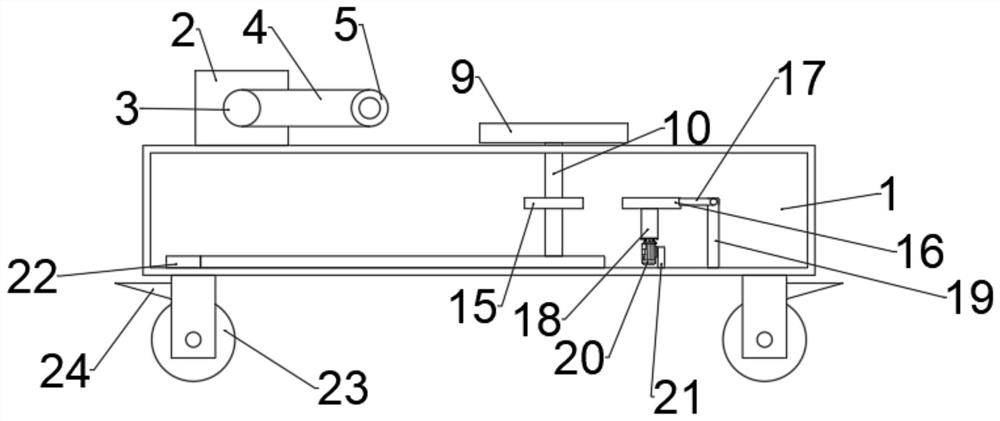

[0029] refer to Figure 1 ~ Figure 3 , a device for trimming rough edges of blockboards, comprising a bottom plate 1, a sliding cavity 6 is opened above the bottom plate 1, a placement plate 9 is slidingly connected to the inside of the sliding cavity 6, and a sliding shaft 10 is connected to the bottom of the positioning plate 9 by bolts, the sliding cavity The center of 6 is provided with a horizontal chute 7, and the left side of the sliding chamber 6 is provided with a vertical chute 8, the sliding shaft 10 slides in the horizontal chute 7 and the vertical chute 8, and the left rear bolt of the bottom plate 1 is connected with a hydraulic The first connecting rod 3 is connected with the bolt on the front side of the pipe 2 and the hydraulic pipe 2, and the end of the first connecting rod 3 away from the hydraulic pipe 2 is rotatably connected with the second connecting rod 4, and the end of the second connecting rod 4 away from the first connecting rod 3 The grinding wheel...

Embodiment 2

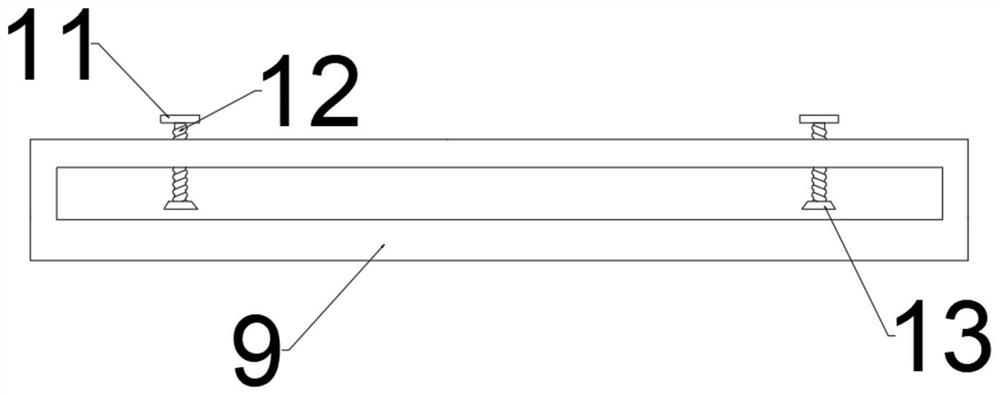

[0037] refer to Figure 4 , a blockboard trimming device, compared with Embodiment 1 in this embodiment, a connecting block 14 is connected to the upper bolt of the placing board 9, and the upper shell wall and the lower shell wall of the placing board 9 are hinged, and the connecting block 14 is provided with several threaded holes, under the condition of hinge, the upper shell wall of placing plate 9 can be opened, and the threaded holes on the connecting block 14 are used to carry out bolt connection, which is convenient for putting in and taking out planks from above, which is convenient Operators operate, increasing its practicability.

[0038] Working principle: In the case of hinge, the upper shell wall of the placement plate 9 can be opened, and the threaded holes on the connection block 14 can be used for bolt connection, which is convenient for the wooden board to be put in and out from above, which is convenient for the operator to operate and increase its practica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com