Dicing knife trimming method for gallium arsenide wafer

A gallium arsenide, dicing technology, applied in other manufacturing equipment/tools, grinding machine parts, grinding/polishing equipment, etc., to reduce dressing time, reduce positive and back avalanches, and reduce poor use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

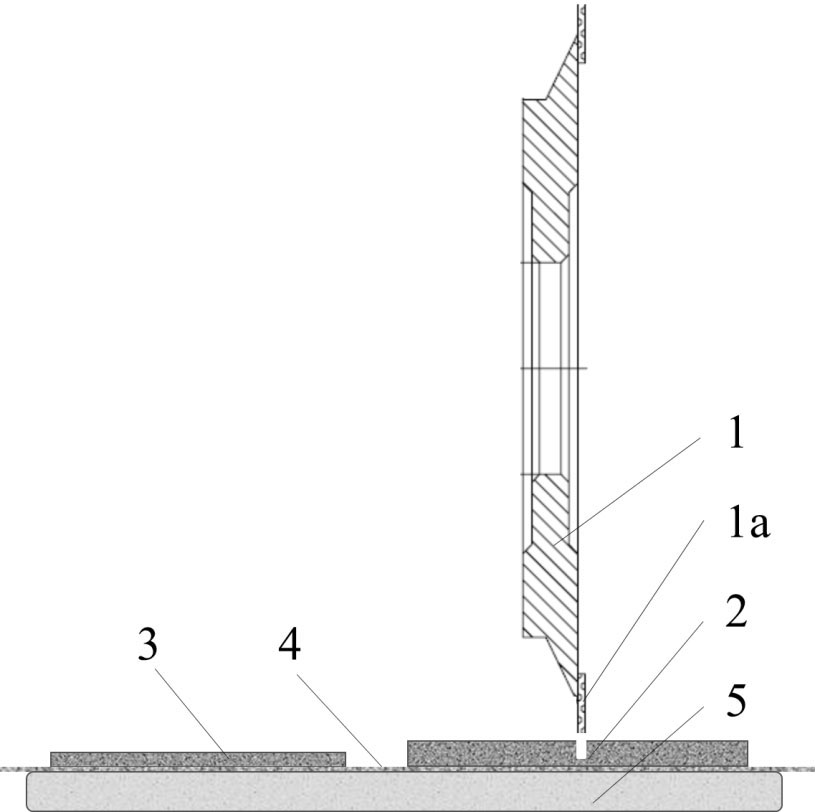

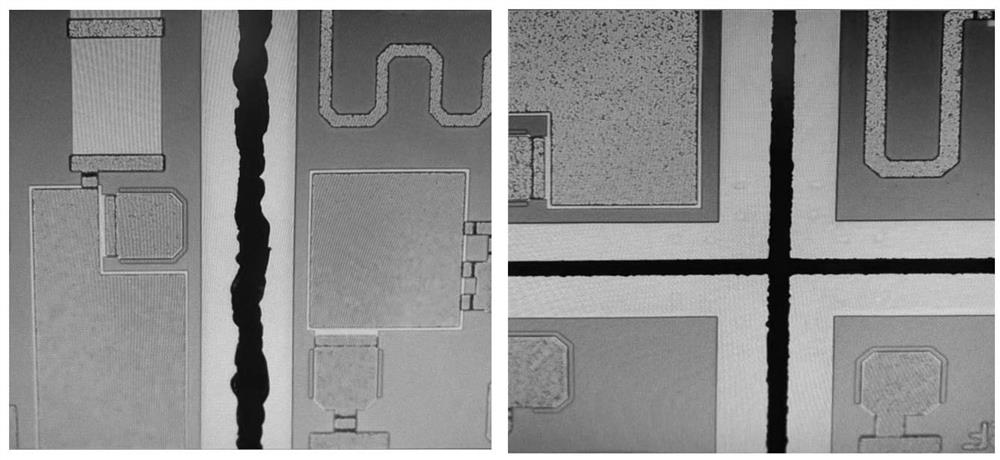

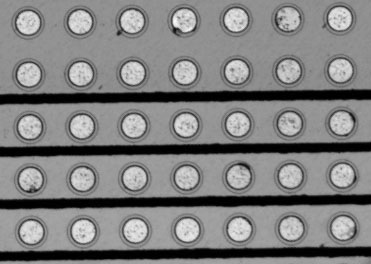

[0021] A method for repairing a gallium arsenide wafer with a dicing knife 1 proposed by the present invention, first uses a sharpening plate 2 to round the outer circle of the knife edge 1a, and then uses a gallium arsenide dummy 3 to sharpen the knife tip, so that the knife edge 1a The abrasive exposure of the tip is more suitable for cutting GaAs wafers. The second purpose is to test the performance of the blade for cutting GaAs. Ensure that the dicing knife 1 has a good initial cutting quality, and after adding 100% cutting performance inspection, the on-site cutting quality is more stable

[0022] The specific steps are: step 1, such as figure 1 As shown, the sharpening plate 2 is fixed on the suction cup 5 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com