Machining method for 5-12 oz thick copper power circuit board drilling

A processing method and circuit board technology, which is applied in the field of circuit board processing, can solve the problems affecting the service life of the spindle, the machining accuracy and quality state, the hole shape and hole position, and the drill bit offset, so as to achieve shortened processing time and short friction time , Reduce the effect of equipment depreciation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

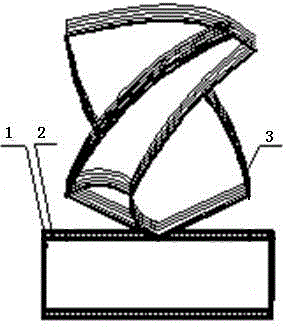

[0023] Embodiments, with reference to the accompanying drawings, a method for drilling a 5-12oz thick copper power supply circuit board is characterized in that the following steps are used:

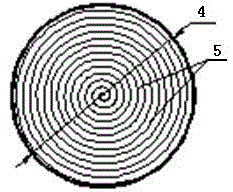

[0024] a. When the diameter of the drilled hole is greater than 2.0mm. Select a drill bit 3 with a diameter of φ1 of 1.55 mm, and use a CNC drilling machine to drill the first pre-drilled hole, the diameter of the first pre-drilled hole is φ.1.55 hole 4;

[0025] b. After the first pre-drilling hole diameter φ.1.55 hole 4 is drilled, when the difference between the designed drilling diameter and the first pre-drilling hole diameter of 1.55mm is greater than 0.45-0.6mm. When drilling the second pre-drilling hole, choose the drill bit diameter φ2 as 1.55mm plus 0.5mm, and drill the second pre-drilling hole;

[0026] c. Similarly, when the difference between the aperture of the second pre-drilling hole and the design aperture is greater than 0.45-0.6mm, the diameter of the drill bit φ3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com