Differential stepless speed-regulation multimode hobbing machine tool

A stepless speed regulation, multi-mode technology, applied in the field of mechanical processing, can solve the problems of chip removal and chip breaking, reduced tool durability, increased cutting heat, etc., to achieve smooth chip removal, reduce cutting force, and reduce cutting hot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

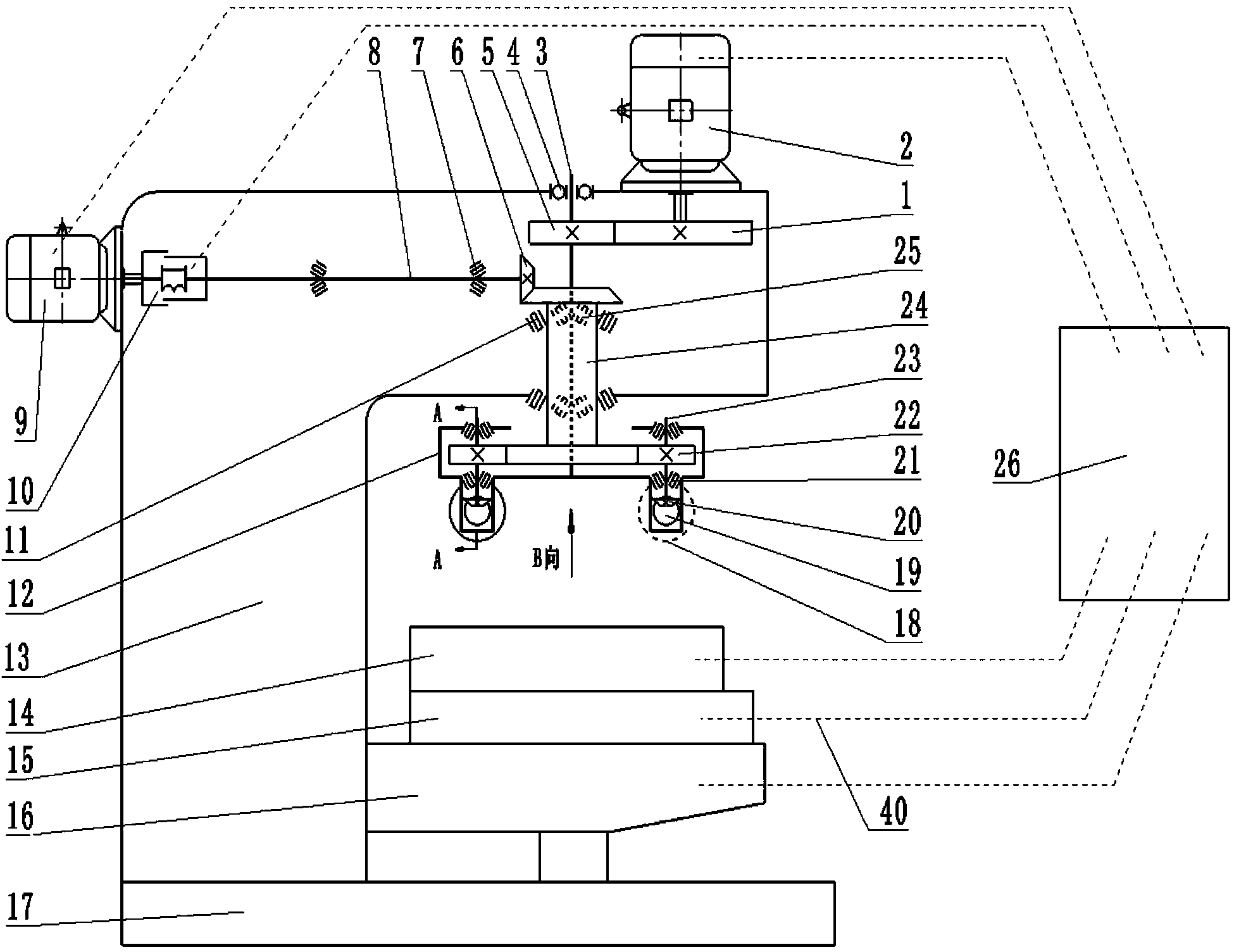

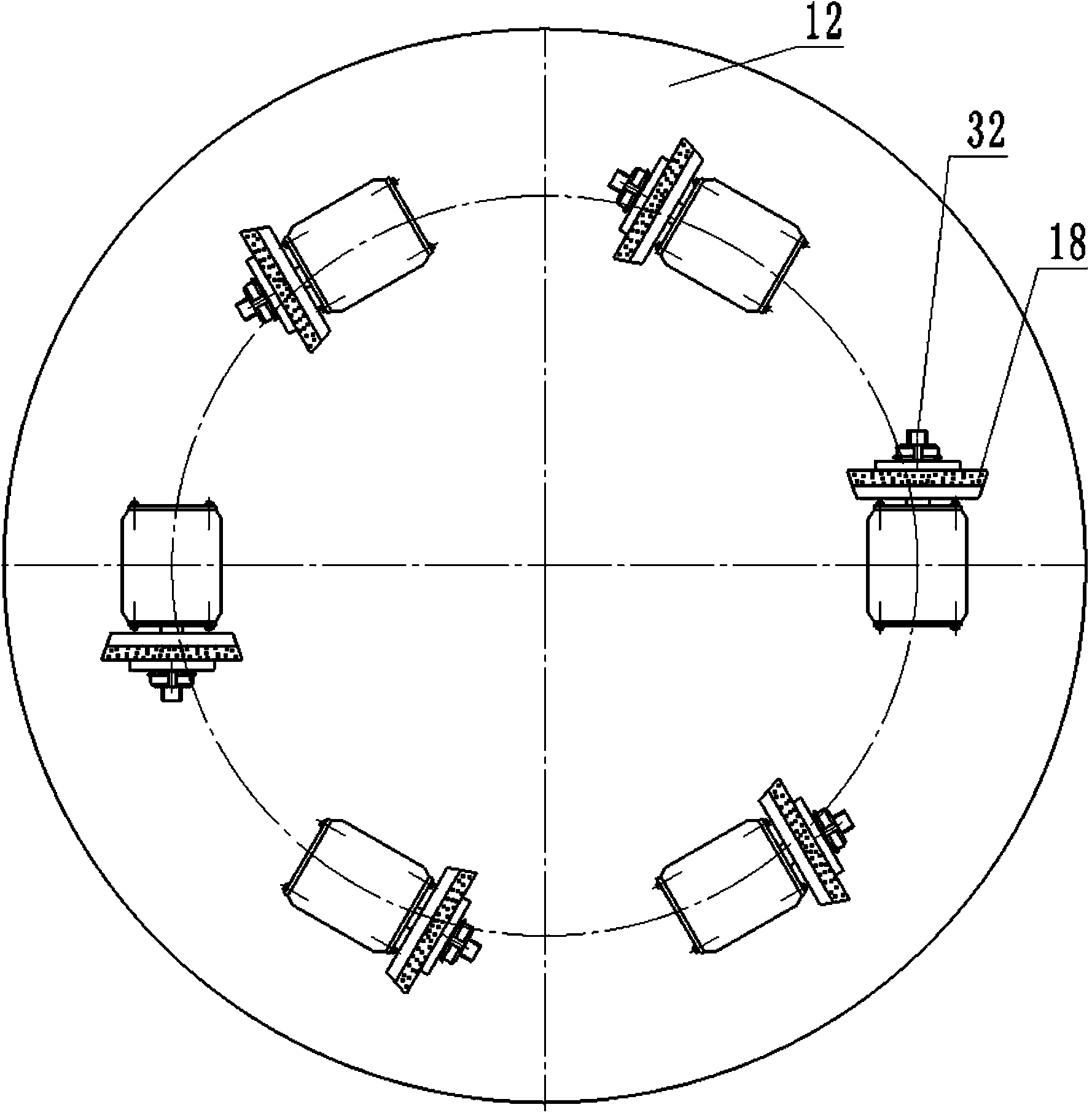

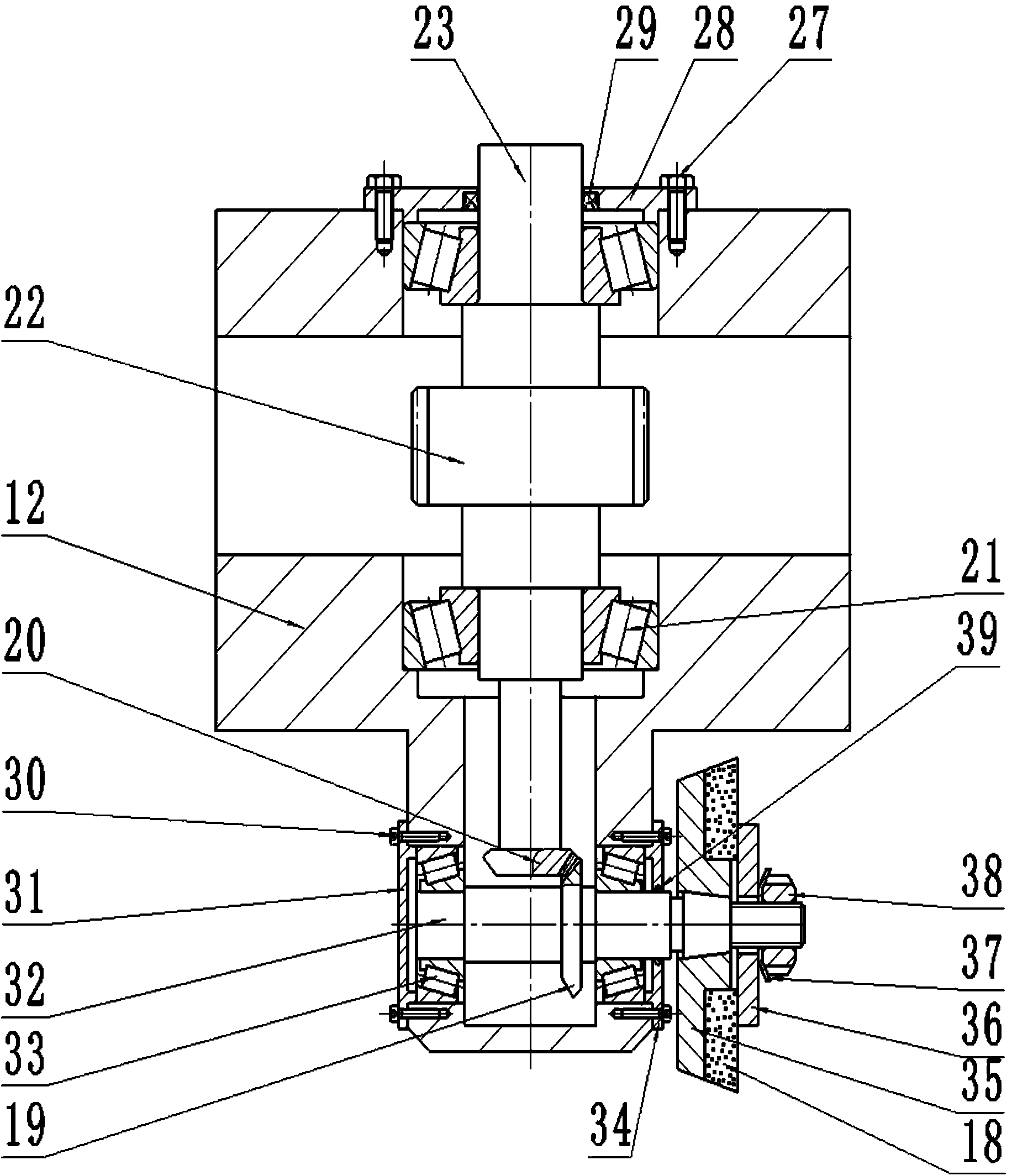

[0019] See attached figure 1 , a multi-mode hobbing and cutting machine tool with stepless differential speed regulation, which includes: a machine tool, a spindle speed regulating motor 2, a speed regulating motor 9, a rotary cutter head 12, a hobbing and cutting device, and a control drive system 26;

[0020] The machine tool includes: a bed 13 and a machine base 17; a machine lifter 16 is connected to the bed 13 and moves up and down along it; a longitudinal feed table 15 is located on the machine lifter 16 and moves left and right along it; 14 is located on the longitudinal feeding table 15 and moves along it;

[0021] The main shaft speed regulating motor 2 is fixedly installed on the bed 13, its output shaft is fixedly connected to the transmission gear 1, the transmission gear 1 meshes with the main shaft gear 5, the main shaft gear 5 is fixedly connected to the main shaft 3, and the main shaft 3 is installed on the bed through the bearing 4 on the main shaft 13;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com