Planetary milling cutter

A planetary and milling cutter technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problems of large plane processing efficiency that affects processing efficiency, large cutting amount affects processing efficiency, and large milling force. Cutting force, reducing cutting heat, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

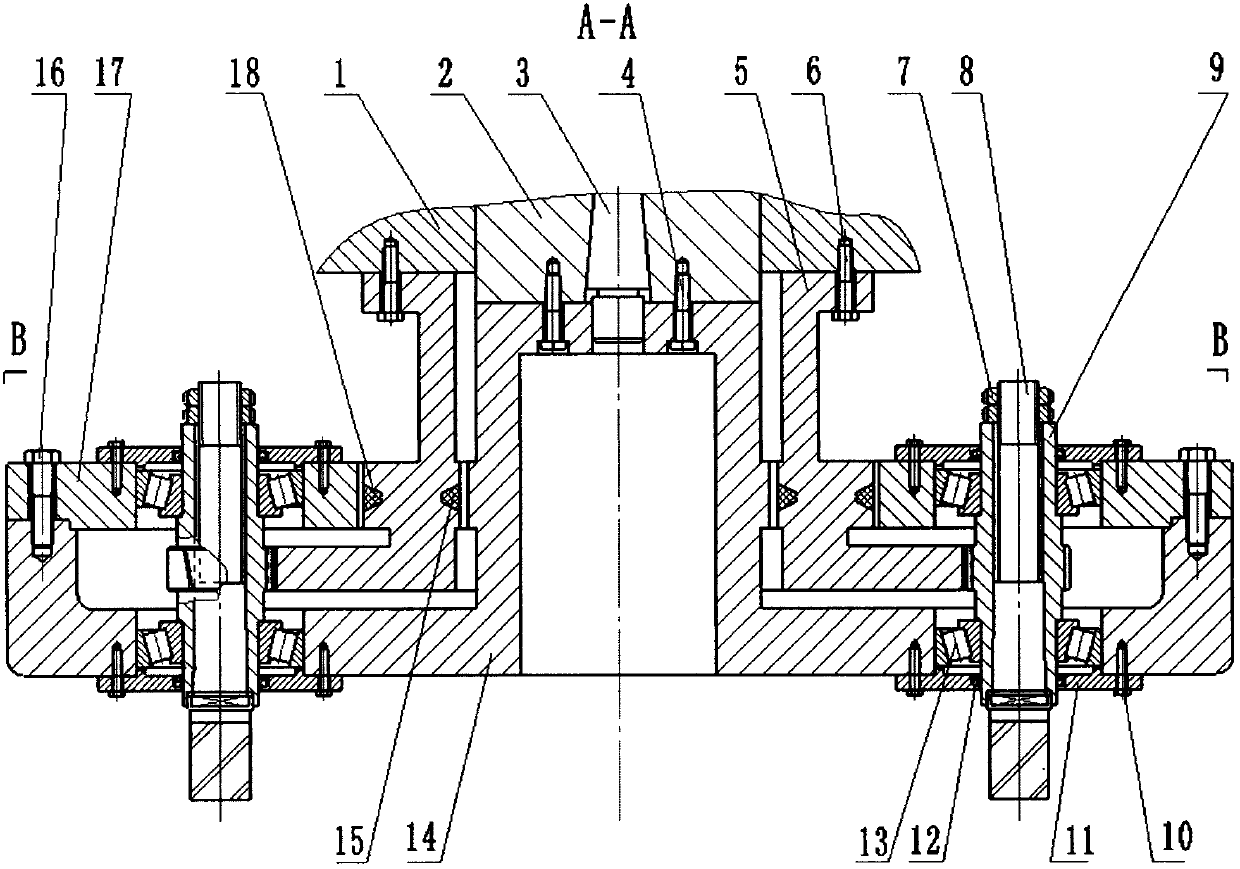

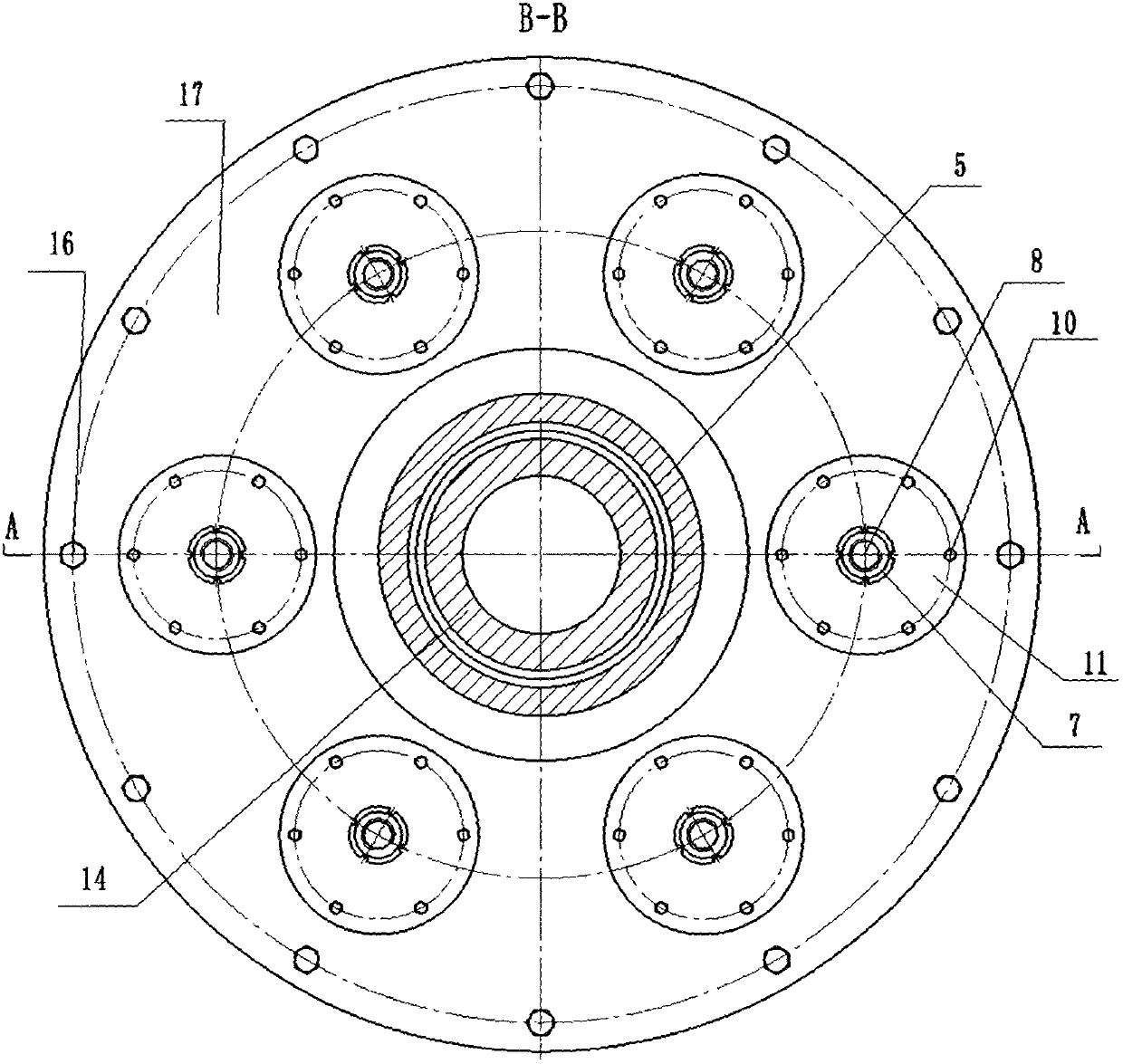

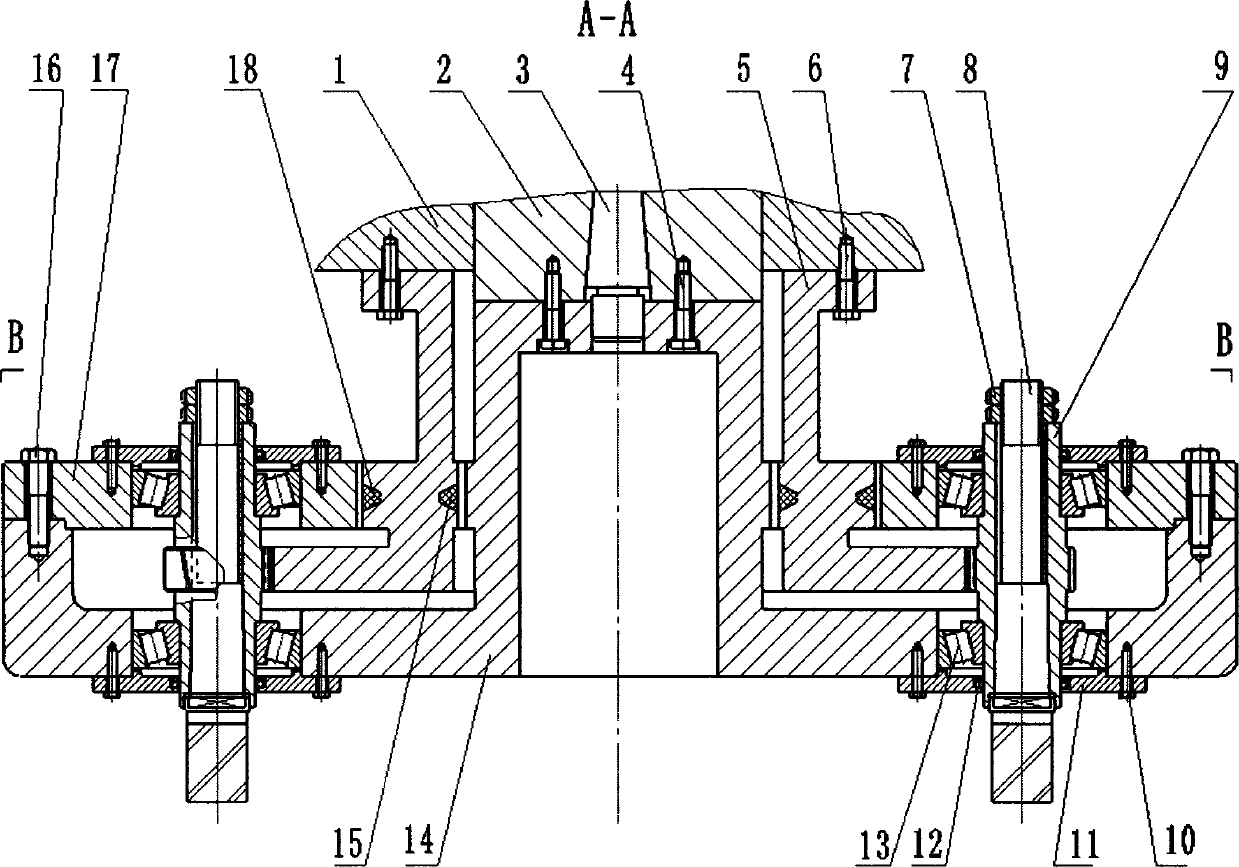

[0010] Planetary milling cutter see figure 1 , figure 2 , including spindle box 1, rotating spindle 2, positioning mandrel 3, fastening screw 4, center bracket 5, bracket bolt 6, round nut 7, split milling cutter shaft 8, planetary sleeve shaft 9, gland screw 10, bearing pressure Cover 11, oil seal 12, bearing 13, rotary cutter head 14, oil seal 15 in the support, bolt 16, cover plate 17 and oil seal 18 outside the support. In the present invention: the positioning mandrel 3 is located in the hole of the rotating main shaft 2 and the rotating cutter head 14, the rotating cutter head 14 is centered with the positioning mandrel 3, connected with the rotating main shaft 2 by the fastening screw 4, and the center support 5 is passed through the support bolt 6 is connected with the spindle box 1, the cover plate 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com