Method for cutting black metal by diamond tool

A diamond tool, ferrous metal technology, used in tool holder accessories, metal processing equipment, metal processing machinery parts, etc., to achieve the effects of easy operation, low macro temperature, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

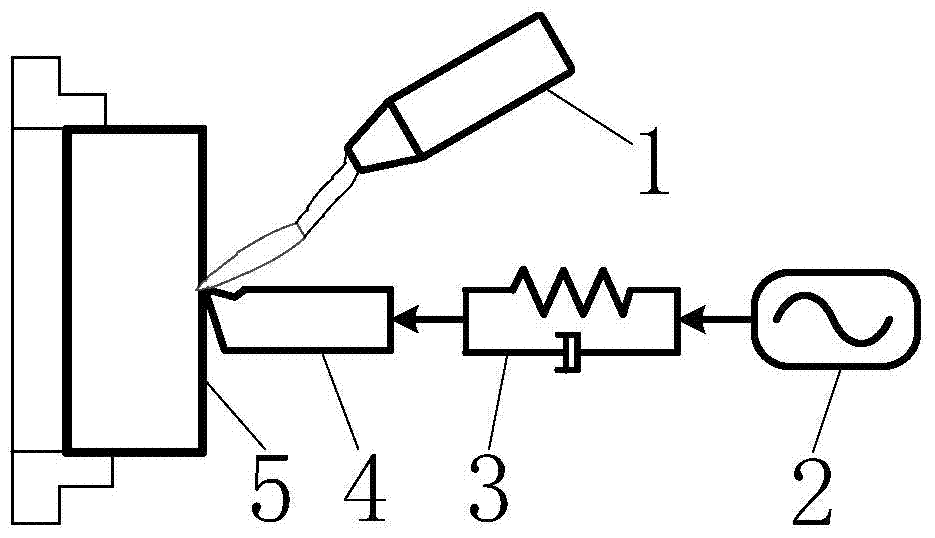

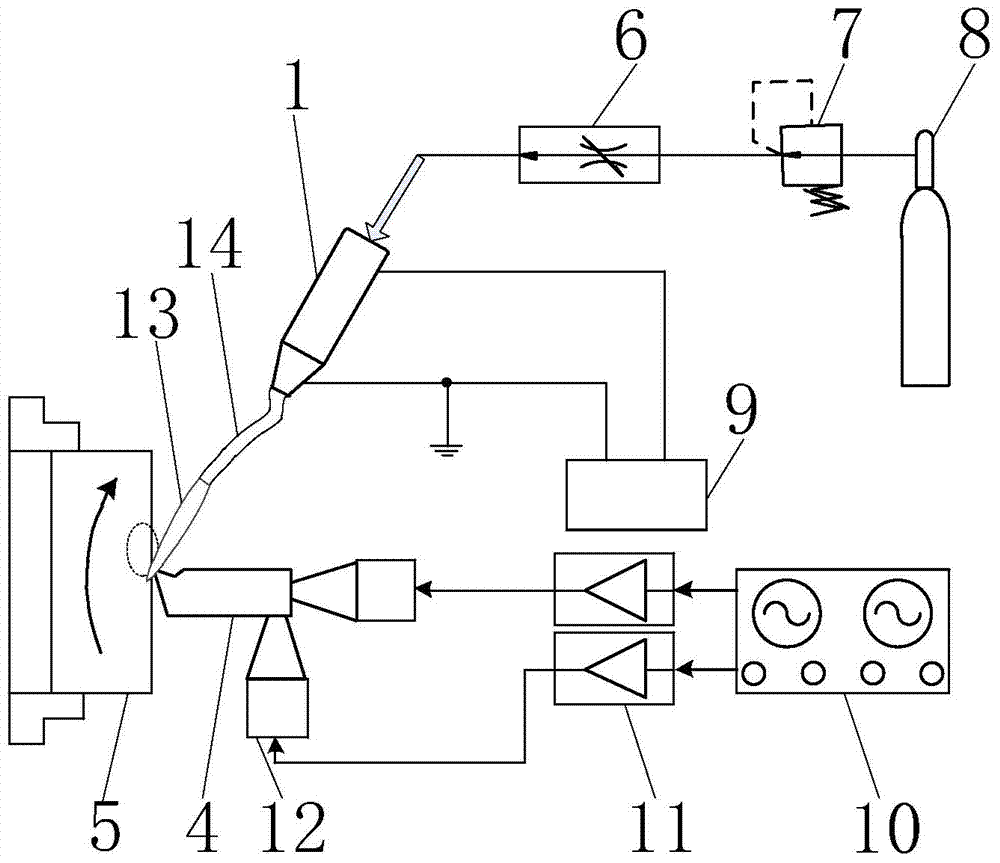

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The invention relates to a method for cutting ferrous metal with a diamond tool. The equipment using the method includes a cold plasma jet generating device and an ultrasonic vibration device.

[0021] The cold plasma generating device includes a graphite needle bare electrode cold plasma jet generator 1 , an adjustable flow meter 6 pressure reducing valve 7 , a working gas source 8 , a high voltage power supply 9 , and a conduit 14 .

[0022] Before cutting, connect these devices respectively according to the drawings: the working gas enters the graphite needle bare electrode cold plasma jet generator 1 from the working gas source 8 through the pressure reducing valve 7 and the adjustable flow meter 6; the high and low pressure of the high voltage power supply 9 The output terminals are respectively connected to the electrodes of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com