Atomizing cold plasma jet generation device

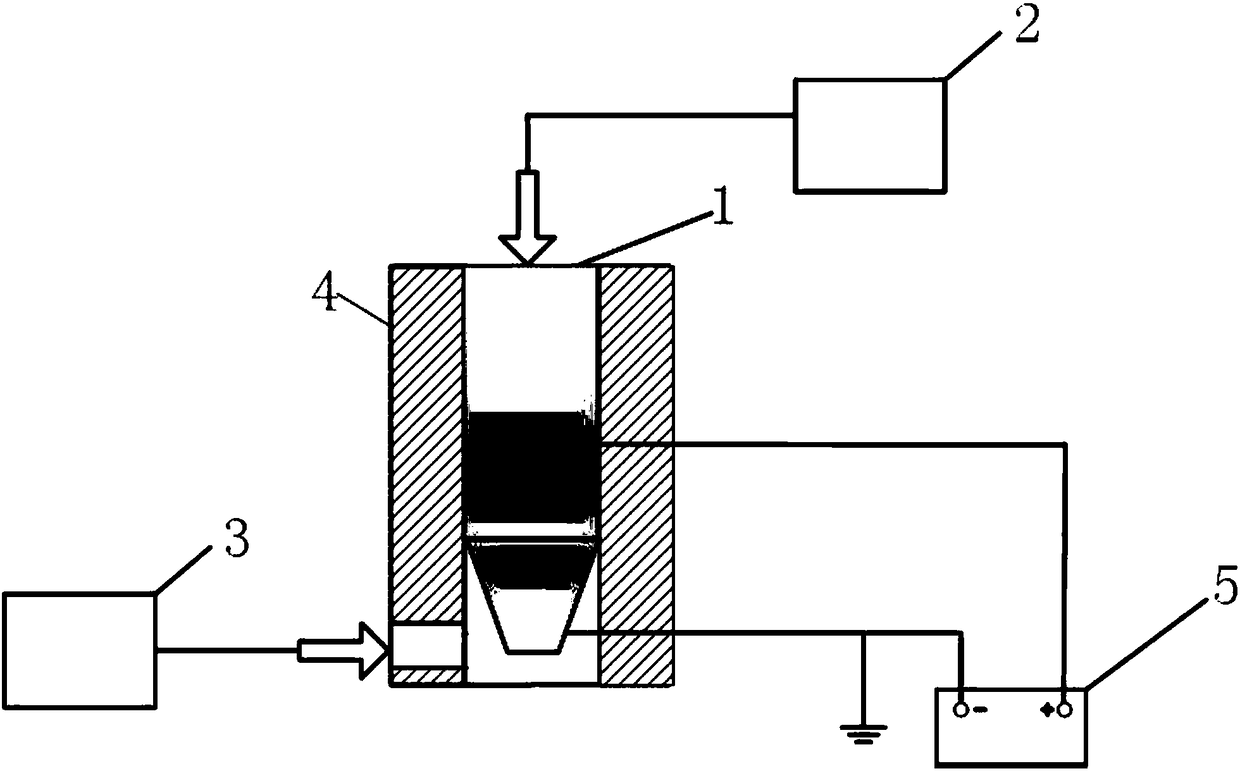

A cold plasma and generating device technology, applied in the direction of plasma, electrical components, etc., can solve the problems of difficult to achieve cooling and lubrication effect, limited cooling effect, difficult heat in cutting contact area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

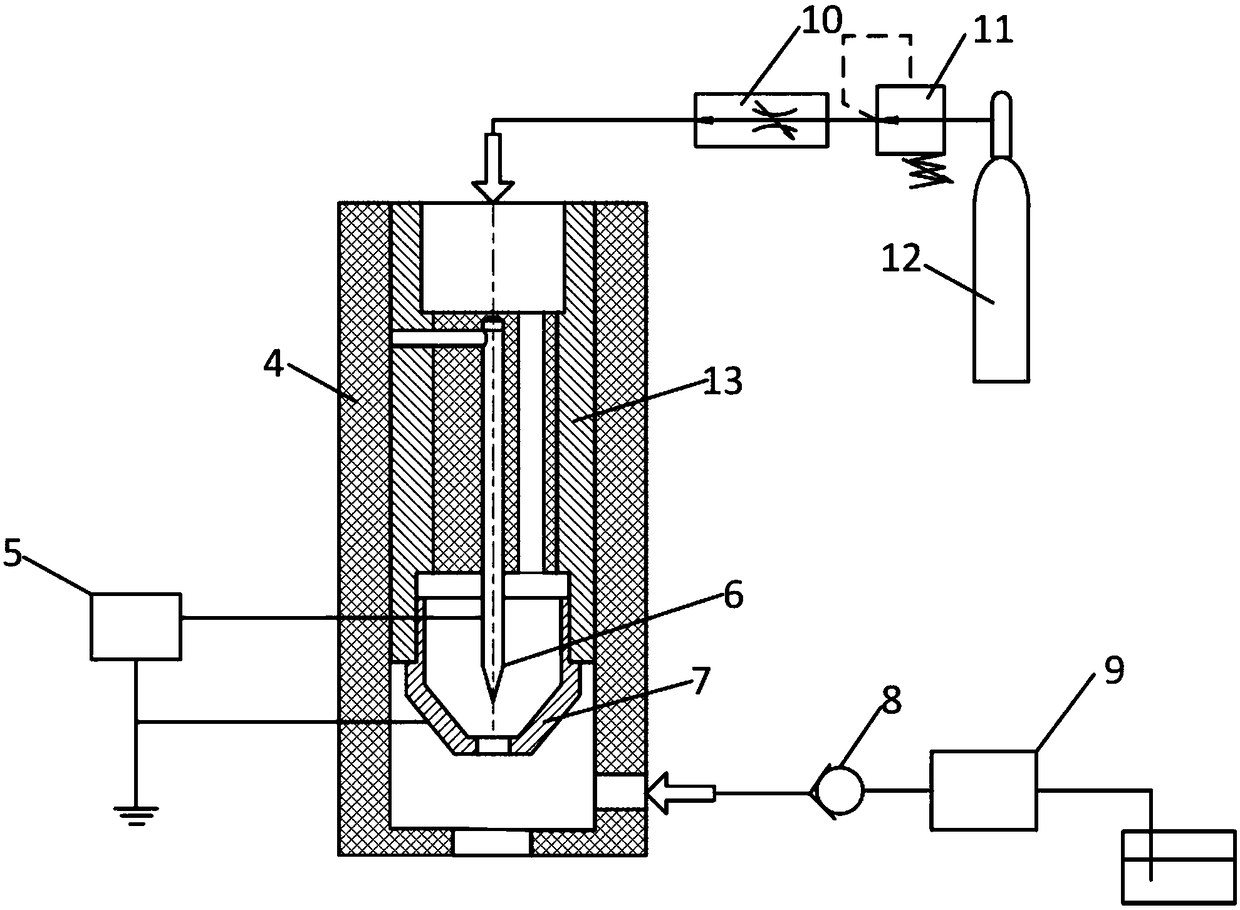

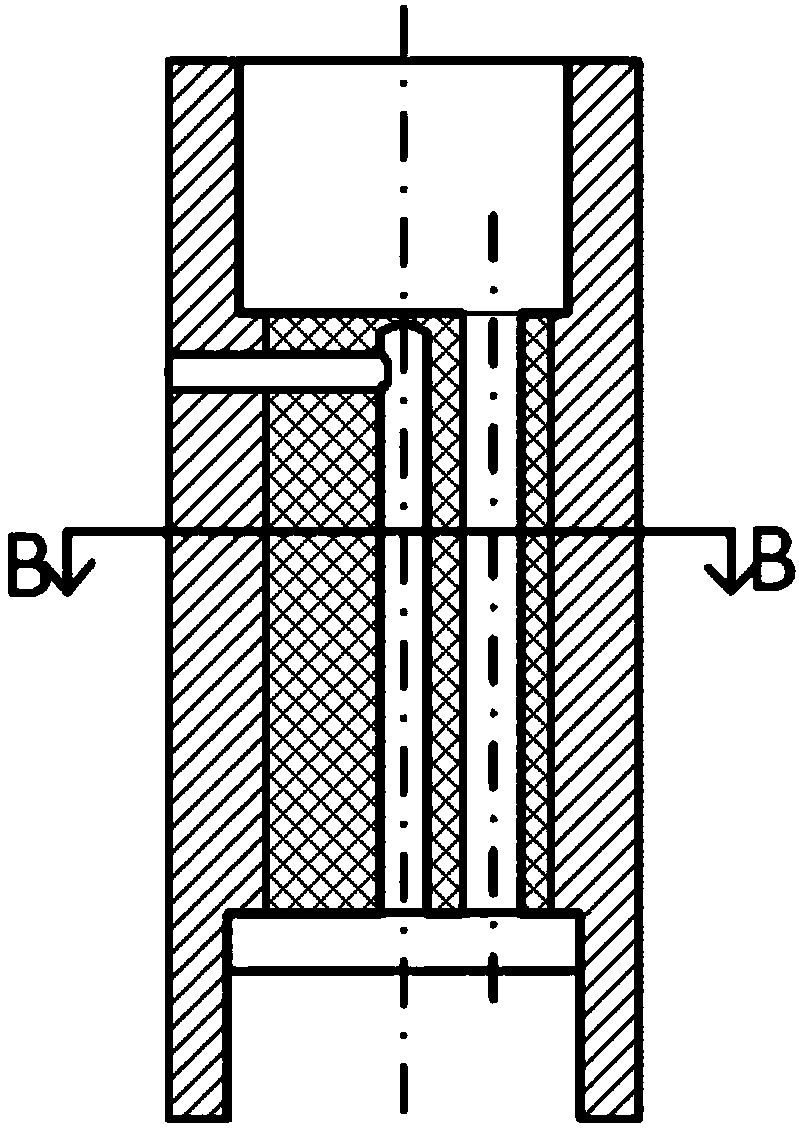

[0025] An atomized cold plasma jet generator, including working gas 12, gas pressure controller 11, and gas flow controller 10, which are sequentially connected through pipelines; the output end of gas flow controller 10 is connected to a cylindrical inner shell through pipelines The tail end of 13; the needle electrode 6 is fixed in the through hole in the center of the cylindrical inner shell 13, the nozzle electrode 7 is fixed on the front end of the cylindrical inner shell 13, and is coaxial with the needle electrode 6; the output end of the high voltage power supply 5 is connected to one end The needle electrode 6, the other end is connected to the nozzle electrode 7 and grounded. The working gas enters the cylindrical inner shell 13 from the tail end through the gas pressure controller 11 and the gas flow controller 10 at a stable flow rate from the working gas source 12, passes through the vent holes uniformly distributed around the needle electrode 6, and enters the noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com