Integral extrusion forming method for asymmetrical assembly parts and apparatus thereof

A technology of extrusion forming and assembling parts, applied in the direction of metal extrusion dies, etc., can solve the problems of complex metal flow, inability to apply actual production, difficult engineering applications, etc., to achieve simple structure, stable work, reduction of mold tooling and The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation will be described in detail below in conjunction with the accompanying drawings (this embodiment is a further description of the present invention, rather than any limitation to the present invention).

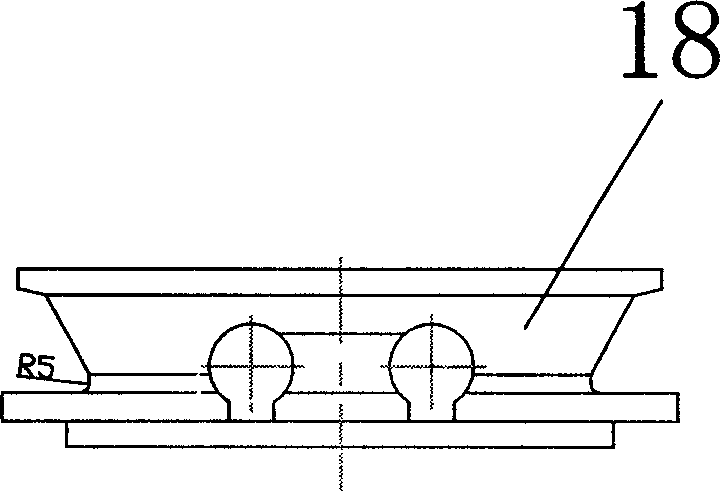

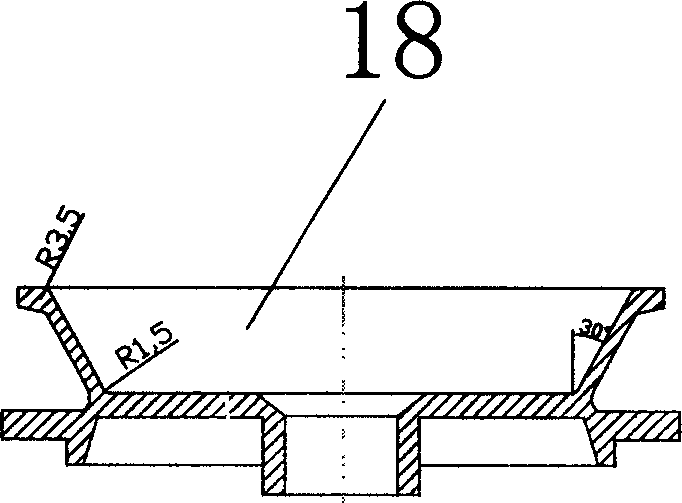

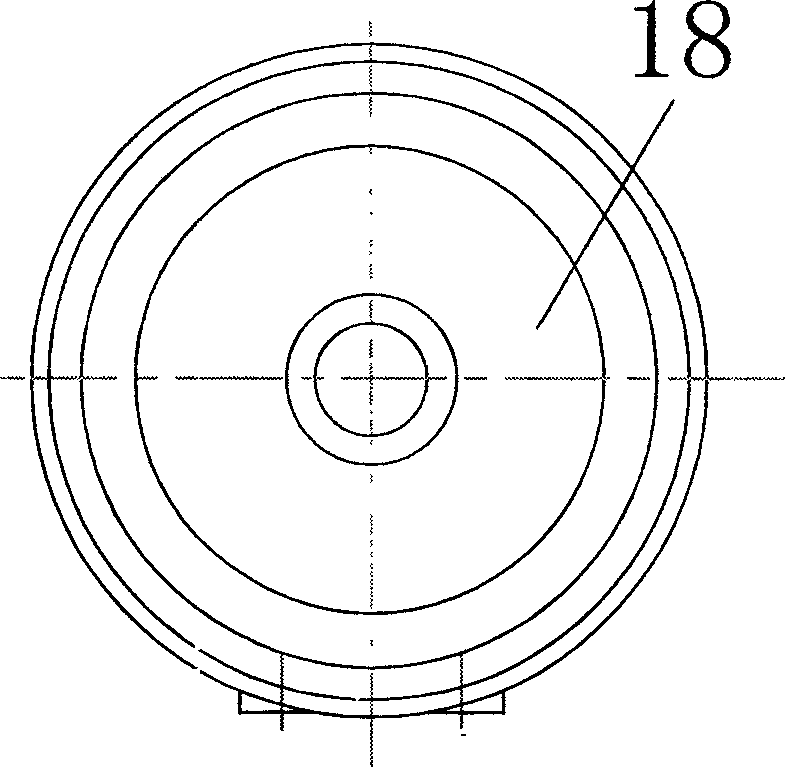

[0027] 1. A truck brake chamber bracket

[0028] figure 1 , figure 2 and image 3 As shown, the brake chamber bracket of a certain truck is a typical part of flange-shaped asymmetric combination; its shape and structure are relatively complex, with flanges on the upper and lower sides, and are irregular, and the side walls have asymmetrically distributed Boss. Reliability requirements are high. Magnesium alloy rods are difficult to process mechanically, with low material utilization and high cost; the casting method has a high scrap rate and poor reliability; and the strength and toughness are difficult to meet its requirements.

[0029] 2. Determine the material and extrusion blank

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com