Method of manufacturing heat sink plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

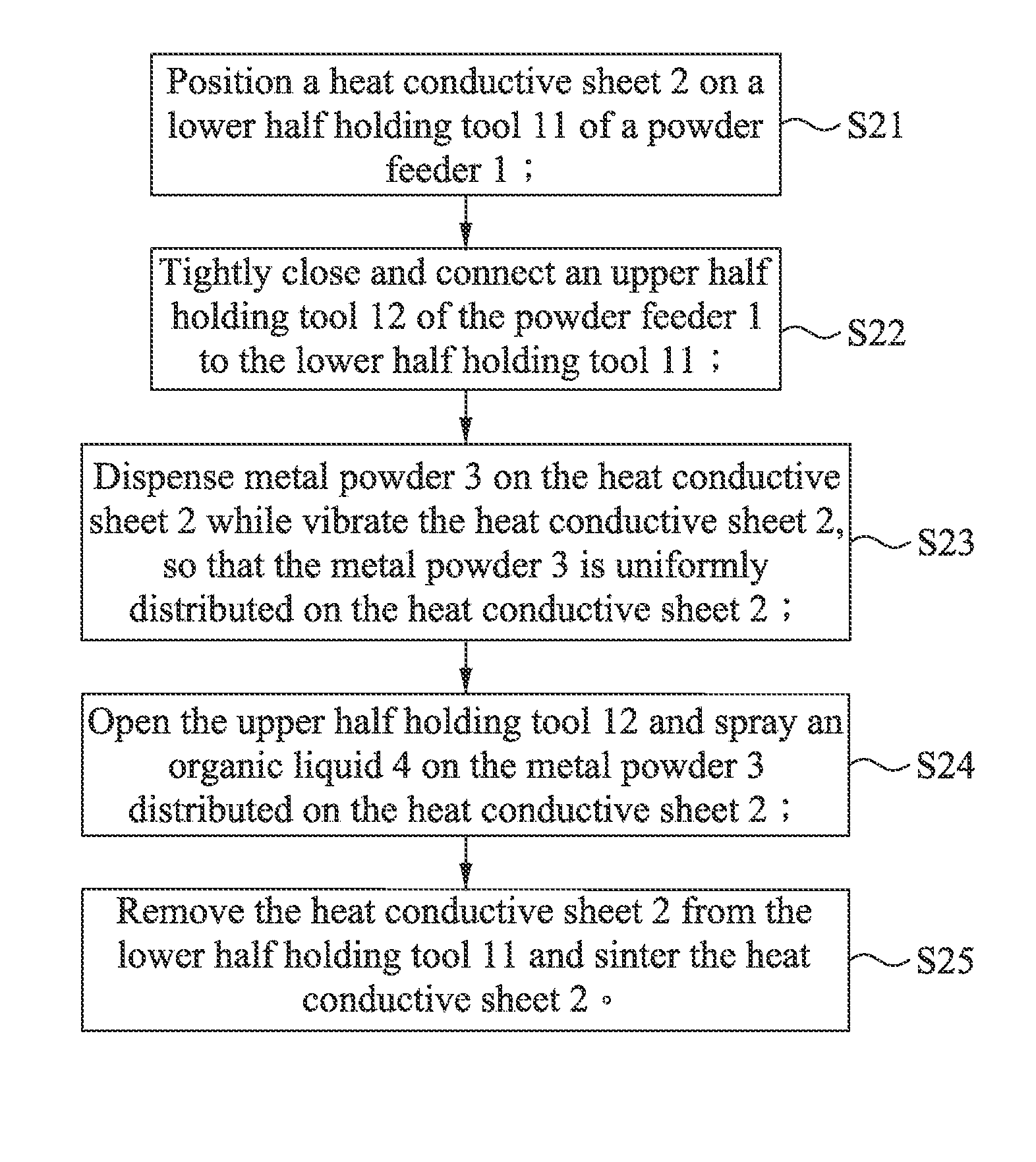

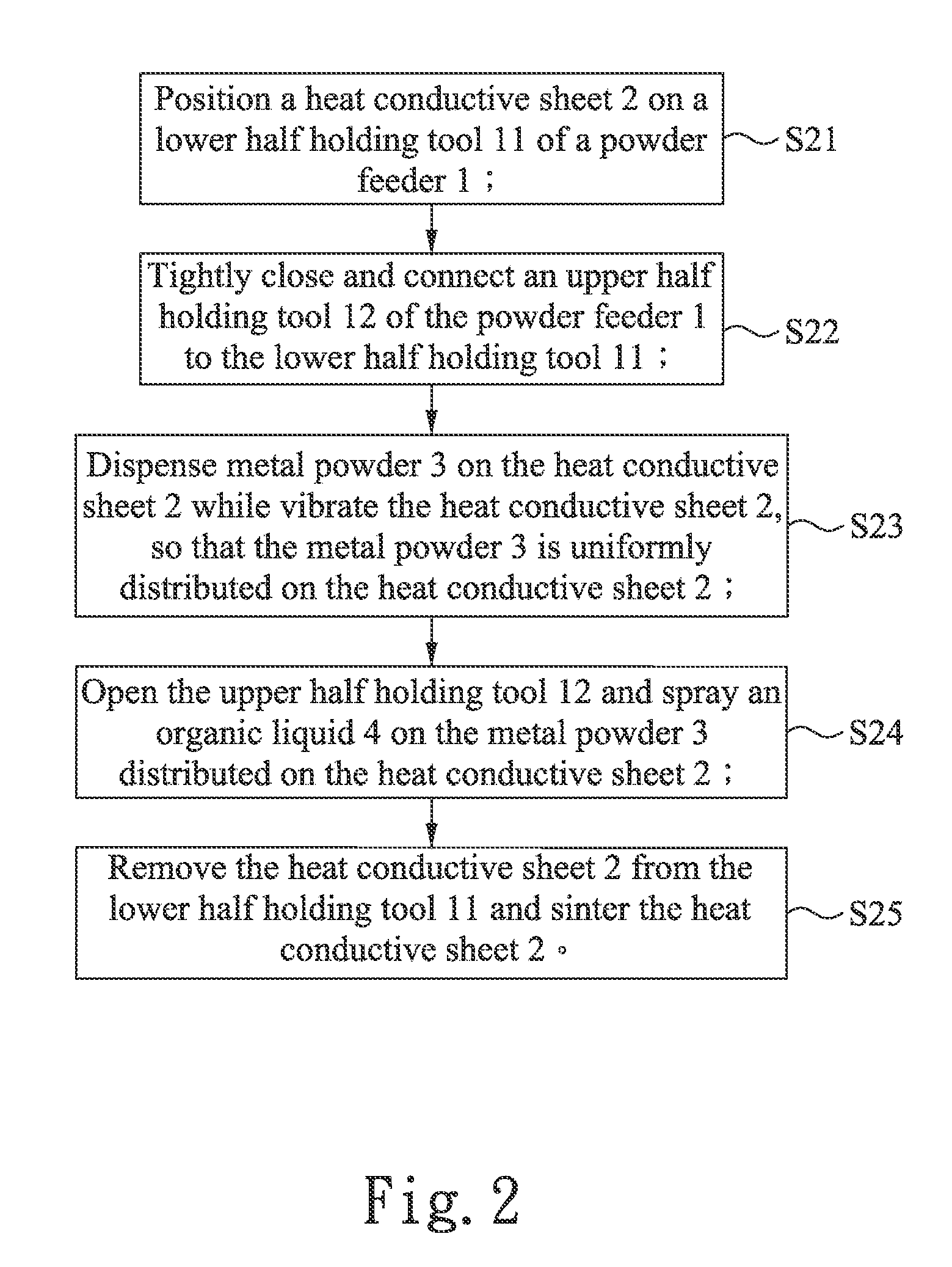

[0022]Please refer to FIG. 2 that is a flowchart showing the steps included in a method of manufacturing heat sink plate according to a first preferred embodiment of the present invention, and to FIGS. 4, 5, 6 and 8 that illustrate the manufacturing of a heat sink plate using the method shown in FIG. 2.

[0023]As shown in FIG. 2, the method of manufacturing heat sink plate according to the first preferred embodiment of the present invention includes the steps of:

positioning a heat conductive sheet 2 on a lower half holding tool 11 of a powder feeder 1 (step S21);

tightly closing and connecting an upper half holding tool 12 of the power feeder 1 to the lower half holding tool 11 (step S22);

dispensing metal powder 3 on the heat conductive sheet 2 while vibrating the heat conducting sheet 2, so that the metal powder 3 is uniformly distributed on the heat conductive sheet 2 (step S23);

opening the upper half holding tool 12 and spraying an organic liquid 4 on the metal powder 3 that has bee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com