Full-automatic crankshaft oil hole machining numerical control machine tool

A technology of crankshaft oil holes and CNC machine tools, which is applied to automatic control devices, metal processing machinery parts, metal processing, etc., can solve the problems of increased crankshaft tip hole wear or bump damage, poor chamfering accuracy, and high labor intensity, etc., to achieve Avoid occupational skin diseases, reduce tool wear, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

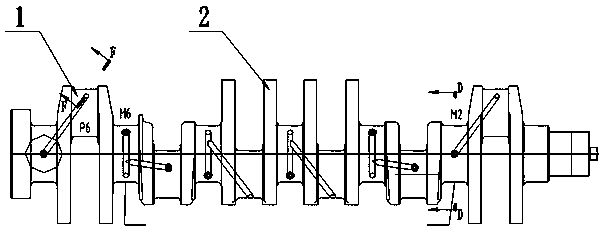

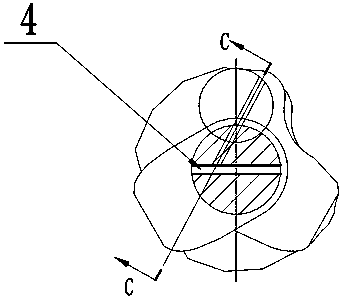

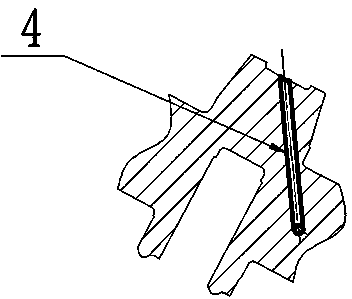

[0050] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 As shown, the present invention is mainly composed of a bed 14, a lateral slide 13, a turntable 12, a vertical column 10, a vertical slide 11, a vertical slide 9, an indexing and indexing fixture 7, and a crankshaft axial positioning fixture , Crankshaft radial positioning fixture, turret power head 8, tool monitoring, measurement and tool setting system, electrical control system, hydraulic control system 63, chip conveyor system, MQL lubrication system and machine tool protection; using turret power head 8. It can realize the automatic processing of drilling straight oil hole leading hole, drilling straight oil hole, drilling inclined oil hole leading hole, drilling inclined oil hole, strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com