Waterproof thin steel plate shearing machine with power adsorption

A technology of shearing machine and thin steel plate, applied in the direction of shearing device, shearing machine equipment, metal processing machinery parts, etc., can solve problems such as flanging, flanging of thin steel plate, pressing pit, etc., and achieves convenient operation and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

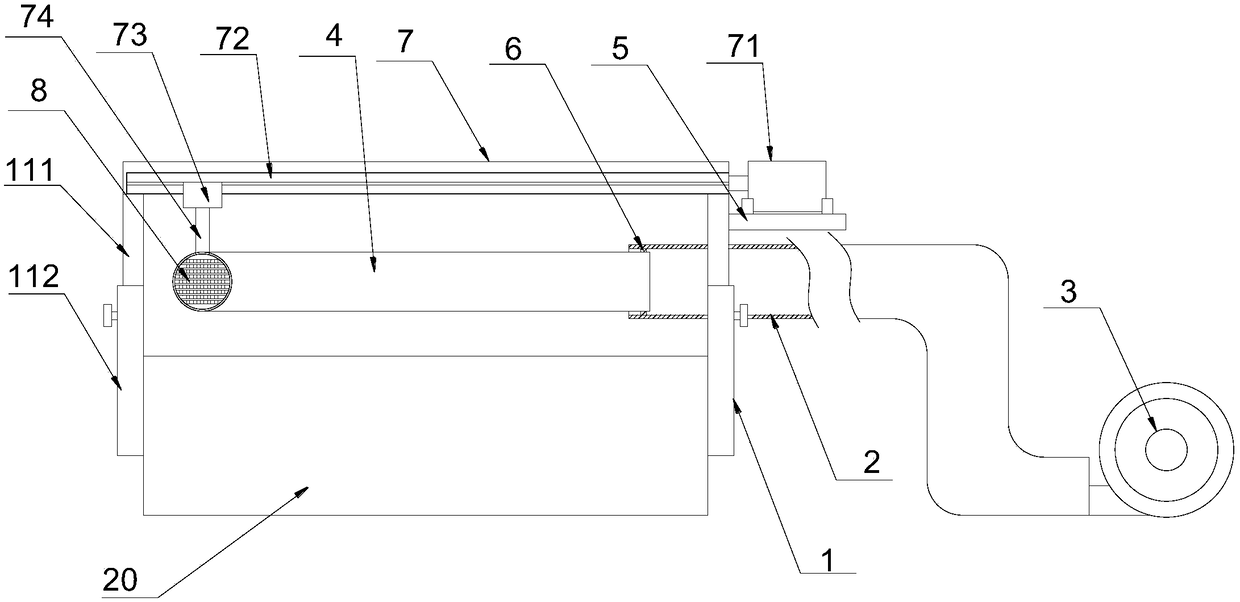

[0028] see Figures 1 to 4 , a waterproof thin steel plate shearing machine with powder suction, comprising a shearing machine main body 20, a shearing knife is arranged on the shearing machine main body 20, and a frame assembly 1 is arranged on both sides of the shearing machine main body 20 , a reciprocating mechanism 7 is arranged between the frame components 1, and the lower end of the reciprocating mechanism 7 is provided with an exhaust pipe-4, and the exhaust pipe-4 is arranged in an "L" shape, and the exhaust pipe-4 One end of the opening is provided with a brush assembly 8, and the other end is sleeved and slidably connected with the exhaust pipe two 2, and the end of the exhaust pipe two 2 is provided with an exhaust fan 3, and the brush assembly 8 is set in conflict with the shearing knife.

[0029] In the present invention, in the process of slitting thin steel plates, the reciprocating mechanism is started, thereby driving the exhaust pipe one to move left and rig...

Embodiment 2

[0032] see Figures 1 to 4 , a waterproof thin steel plate shearing machine with powder suction, comprising a shearing machine main body 20, a shearing knife is arranged on the shearing machine main body 20, and a frame assembly 1 is arranged on both sides of the shearing machine main body 20 , a reciprocating mechanism 7 is arranged between the frame components 1, and the lower end of the reciprocating mechanism 7 is provided with an exhaust pipe-4, and the exhaust pipe-4 is arranged in an "L" shape, and the exhaust pipe-4 One end of the opening is provided with a brush assembly 8, and the other end is sleeved and slidably connected with the exhaust pipe two 2, and the end of the exhaust pipe two 2 is provided with an exhaust fan 3, and the brush assembly 8 is set in conflict with the shearing knife.

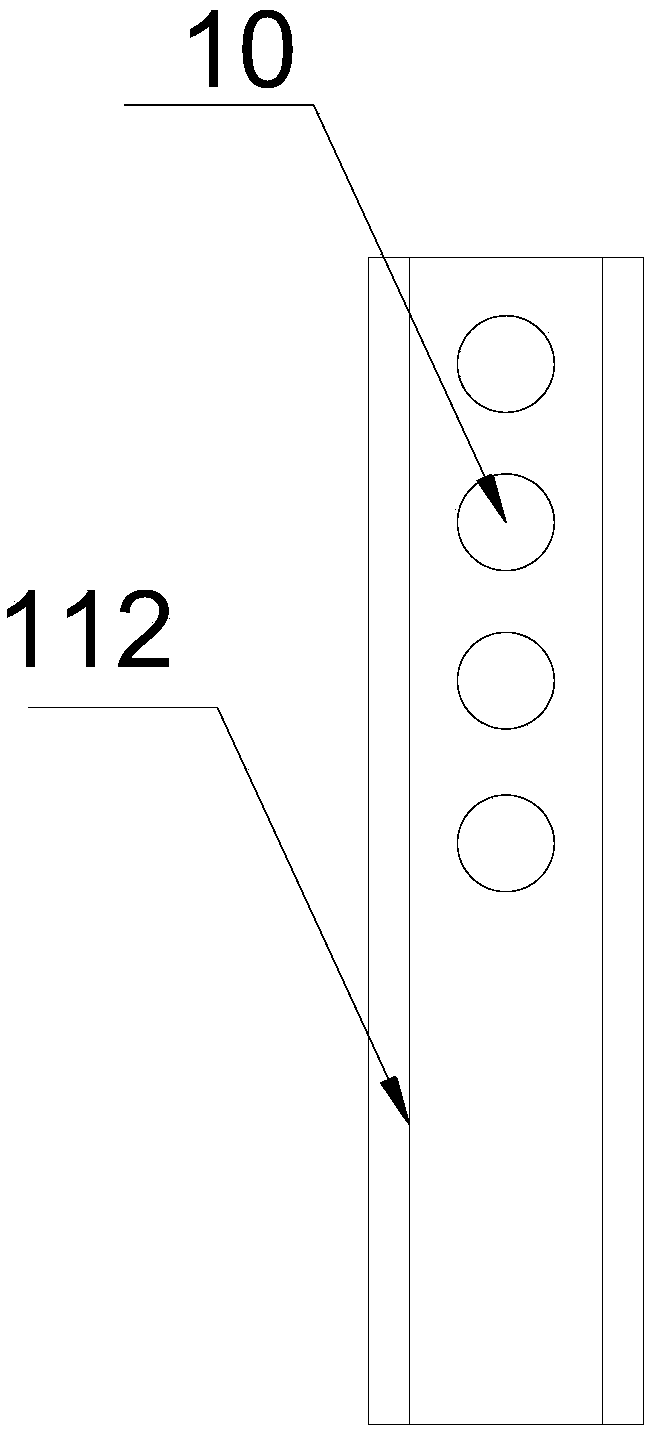

[0033] Reciprocating mechanism 7 comprises screw drive mechanism 7, and described lead screw drive mechanism 7 comprises screw mandrel 72 and slide block 73, and described slid...

Embodiment 3

[0038] see Figures 1 to 4 , a waterproof thin steel plate shearing machine with powder suction, comprising a shearing machine main body 20, a shearing knife is arranged on the shearing machine main body 20, and a frame assembly 1 is arranged on both sides of the shearing machine main body 20 , a reciprocating mechanism 7 is arranged between the frame components 1, and the lower end of the reciprocating mechanism 7 is provided with an exhaust pipe-4, and the exhaust pipe-4 is arranged in an "L" shape, and the exhaust pipe-4 One end of the opening is provided with a brush assembly 8, and the other end is sleeved and slidably connected with the exhaust pipe two 2, and the end of the exhaust pipe two 2 is provided with an exhaust fan 3, and the brush assembly 8 is set in conflict with the shearing knife.

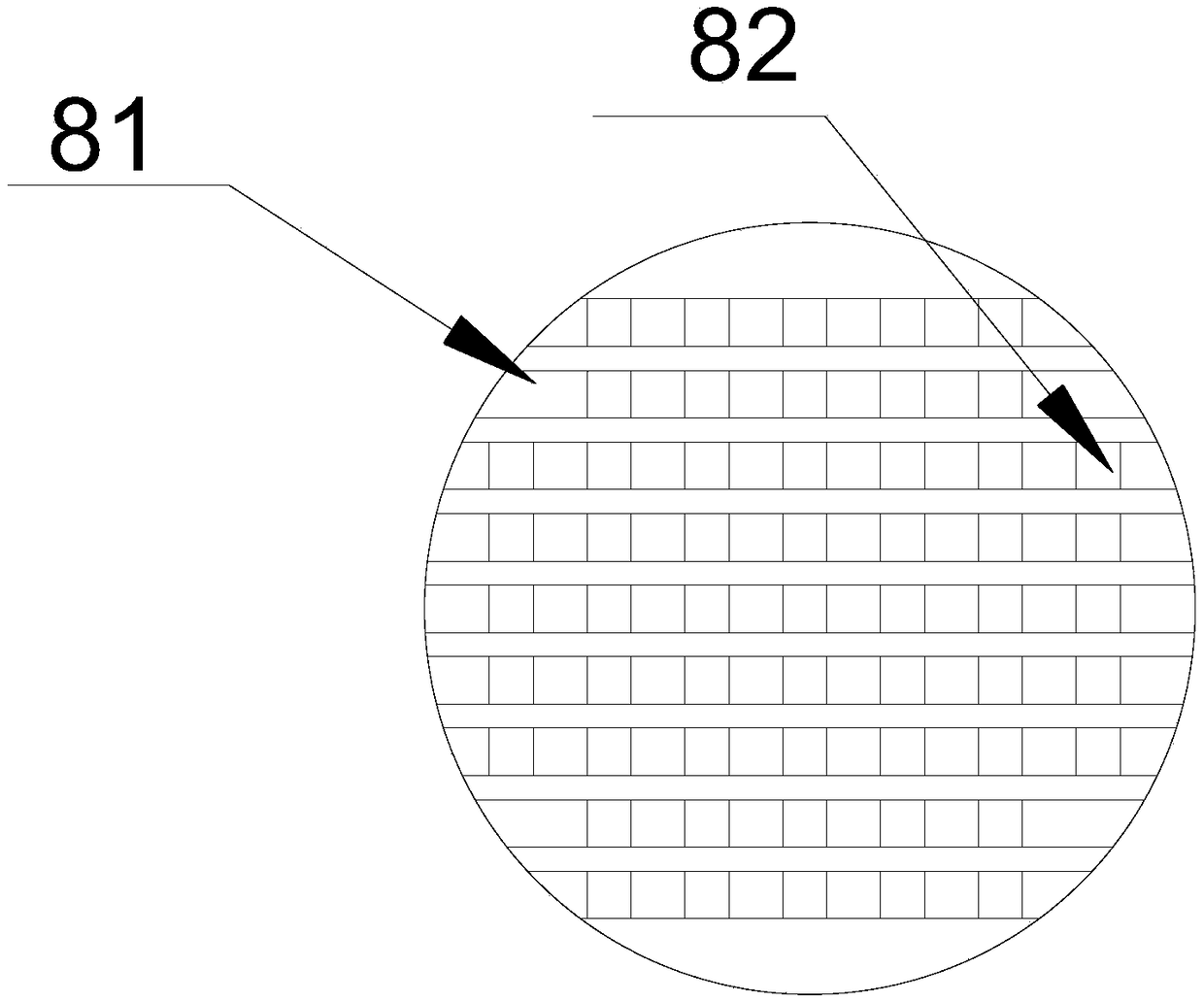

[0039] The brush assembly 8 includes a plurality of sets of installation strips 81 evenly arranged in the exhaust pipe-4, gaps are provided between each of the installation str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com