Mask nose bridge strip performance detection equipment

A testing equipment and mask technology, applied in the field of mask nose bridge performance testing equipment, can solve the problem of not being able to detect the bending resistance of the mask nose bridge, and achieve the effects of convenient bending operation, avoiding flanging and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

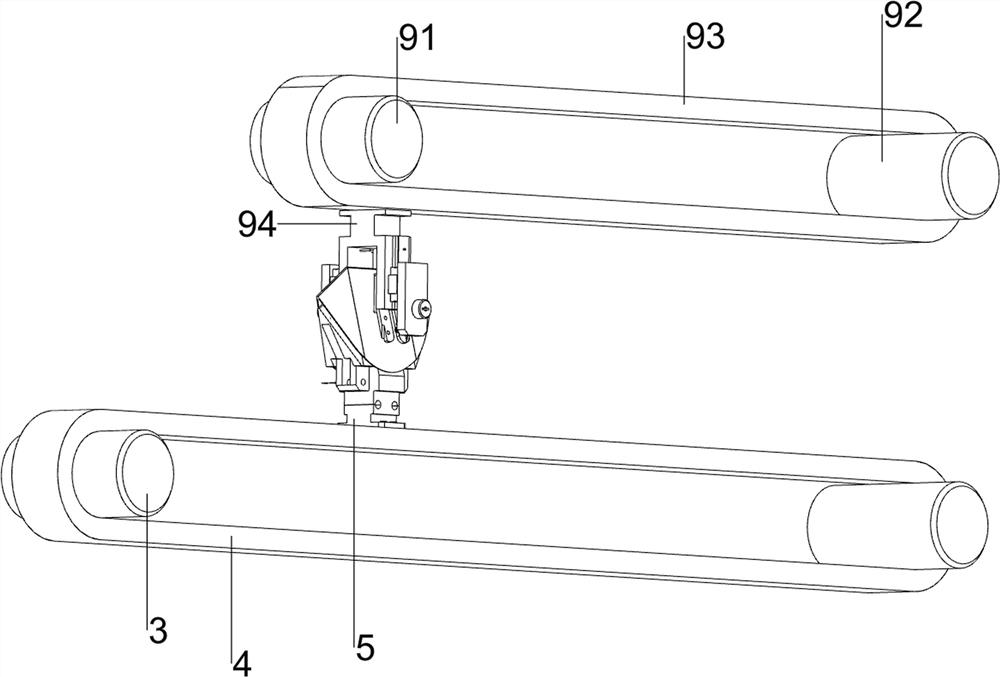

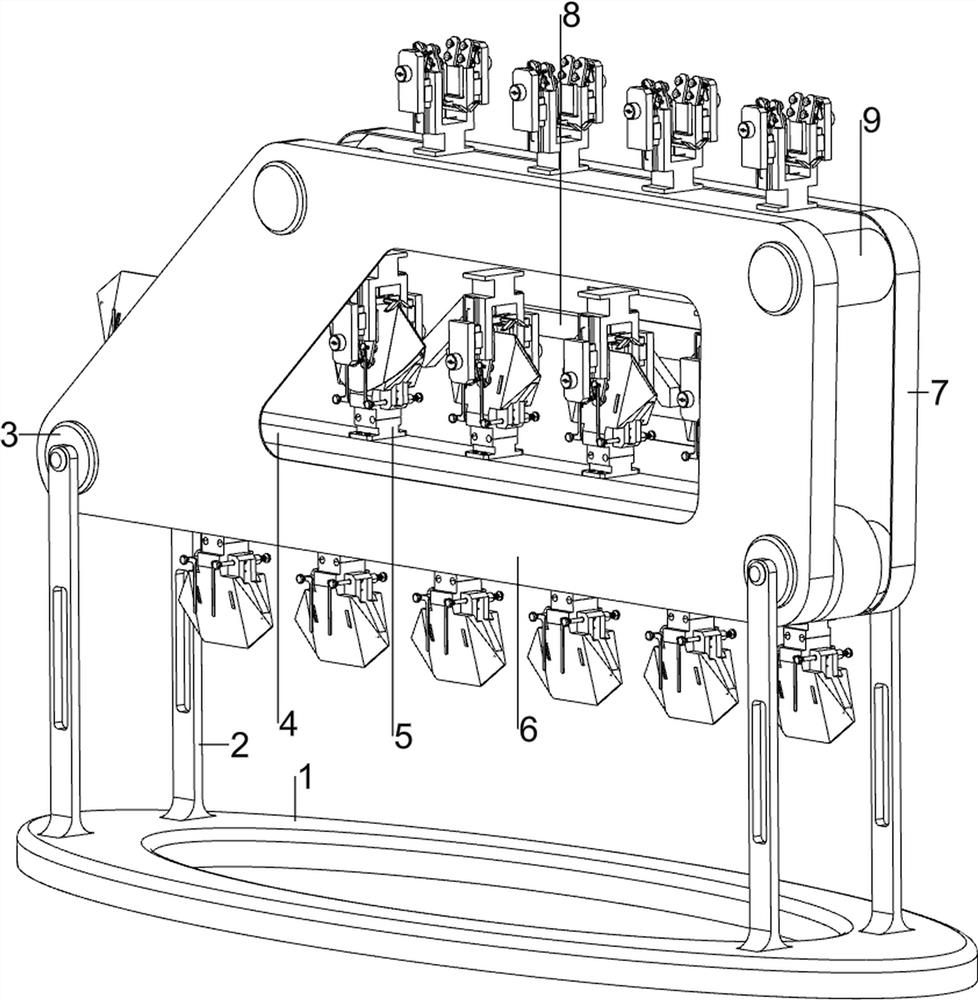

[0037] A mask nose bridge performance testing equipment, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, including support frame 1, support rod 2, first roller 3, first conveyor belt 4, mask mold 5, first shell 6, second shell 7, long rod 8, unqualified mask take-away mechanism 9 and In the nose bridge test mechanism 10, the top left and right sides of the support frame 1 are symmetrically welded with support rods 2 front and rear, and the upper parts of the two support rods 2 on the same side in the longitudinal direction are connected with a first roller 3 by means of bearings, and the first roller 3 A first conveyor belt 4 is wound in between, the mask molds 5 are evenly spaced on the first conveyor belt 4, a first shell 6 is rotatably connected between the front sides of the first rollers 3, and the rear sides of the first rollers 3 are connected. A second shell 7 is connected in a rotary manner, and a long rod 8 is provided in the middle of the first sh...

Embodiment 2

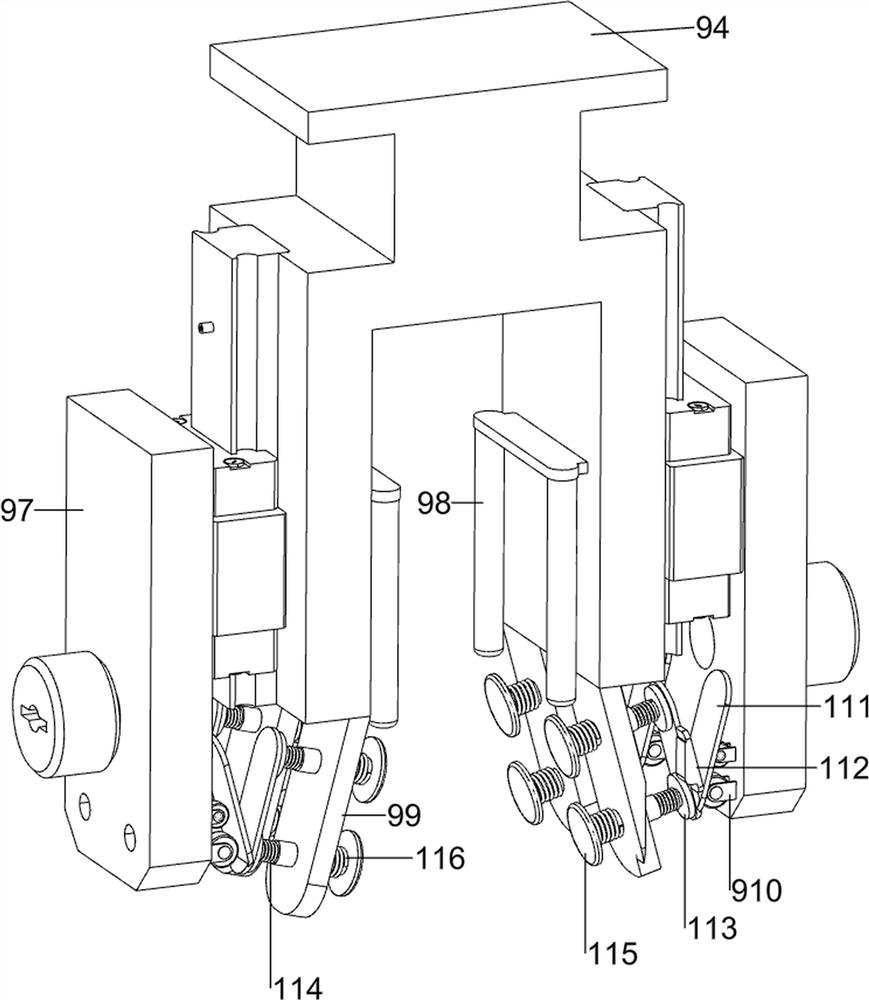

[0042] On the basis of Example 1, as Figure 4 and Figure 9 As shown, it also includes a mask fixing mechanism 11, and the mask fixing mechanism 11 includes a third fixing block 111, a first magnet 112, a first pressing frame 113, a first tension spring 114, a second pressing frame 115 and a second tension spring 116. The left and right sides of the first fixing block 99 are slidably provided with a second pressing frame 115. The second pressing frame 115 slides inward to fix both sides of the lower part of the mask. The inner side of the second pressing frame 115 is surrounded by a second tension spring 116. , the two ends of the second tension spring 116 are respectively connected with the second pressing frame 115 and the first fixing block 99, the outer side of the second pressing frame 115 is slidably provided with the first pressing frame 113, the first pressing frame 113 and the second pressing frame The first tension springs 114 are connected between the 115 . The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com