ITO membrane bending resistant characteristic test device

A technology of characteristic testing and testing device, which is applied in the direction of applying stable bending force to test the strength of materials, which can solve the problems of high frequency misjudgment and low reliability, and achieve the effect of improving the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

[0027] The structure of the ITO film bending resistance characteristic testing device of the present embodiment is as follows:

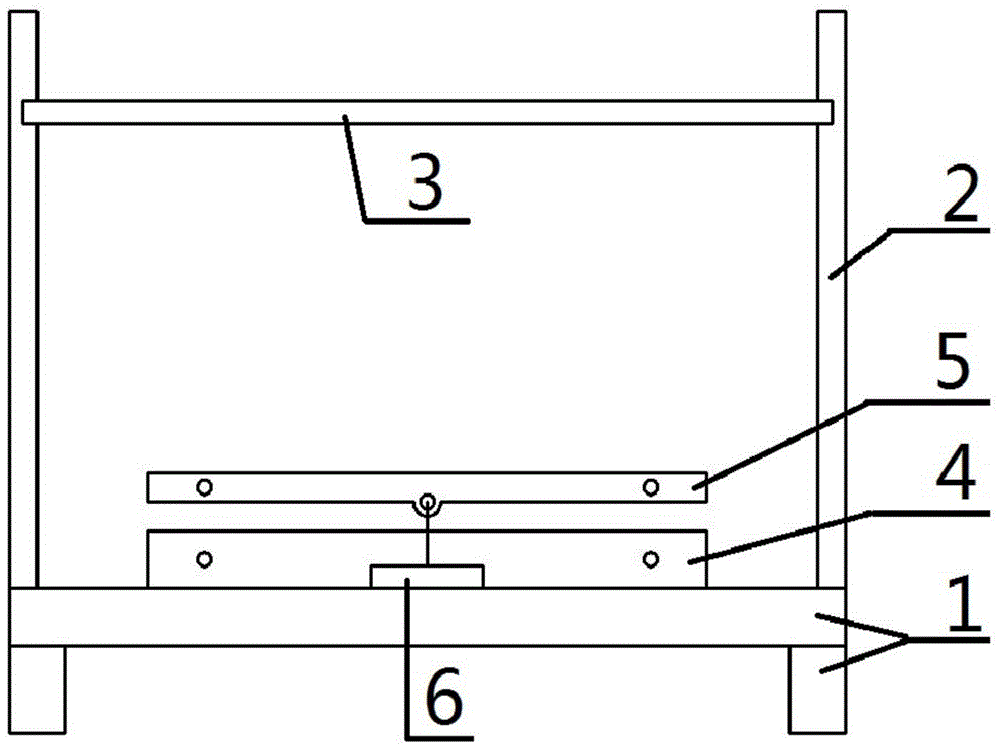

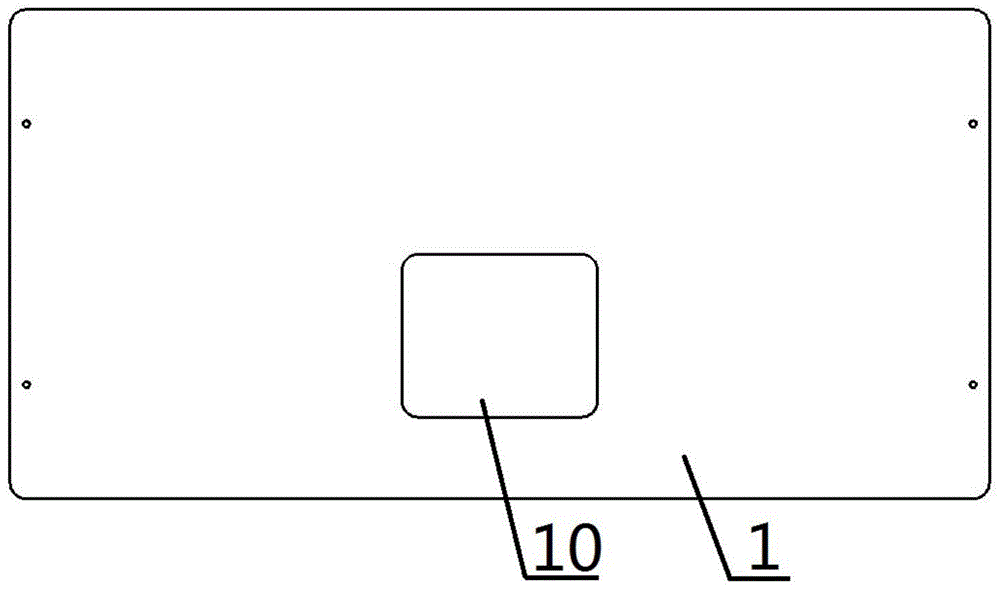

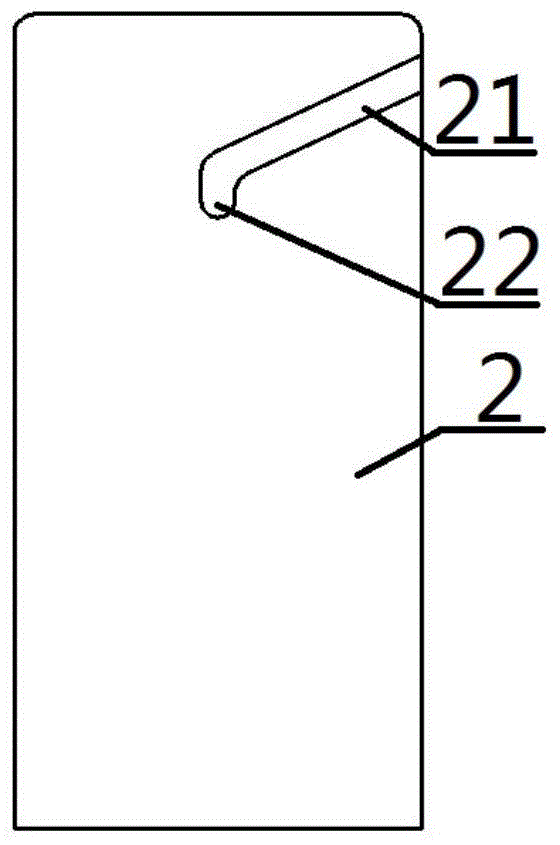

[0028] Please combine figure 1 It should be understood that the present embodiment provides a test device for bending resistance of an ITO film, which is used to bend an ITO film. The test device includes a base 1, two supporting side plates 2, a cylindrical rod 3, a first Fixing fixture 4 and a second fixing fixture 5, these support side plates 2 are arranged on both sides of the base 1 parallel to each other, the cylindrical rod 3 is fixed between the two support side plates 2 and is located on the base 1 Above, the first fixing fixture 4 is fixed on the base 1 and the clamping slot of the first fixing fixture 4 is parallel to the cylindrical rod 3. When in use, the ITO film bypasses the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com